For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

165/273

(13) Assemble the parts after cleaning and greasing has been completed.

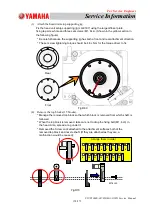

First, the spring is attached onto the nozzle shaft. Before it, apply grease (Daphne

Eponex No. 1) on the two locations on the both side as shown in the figure, after the

cleaning.

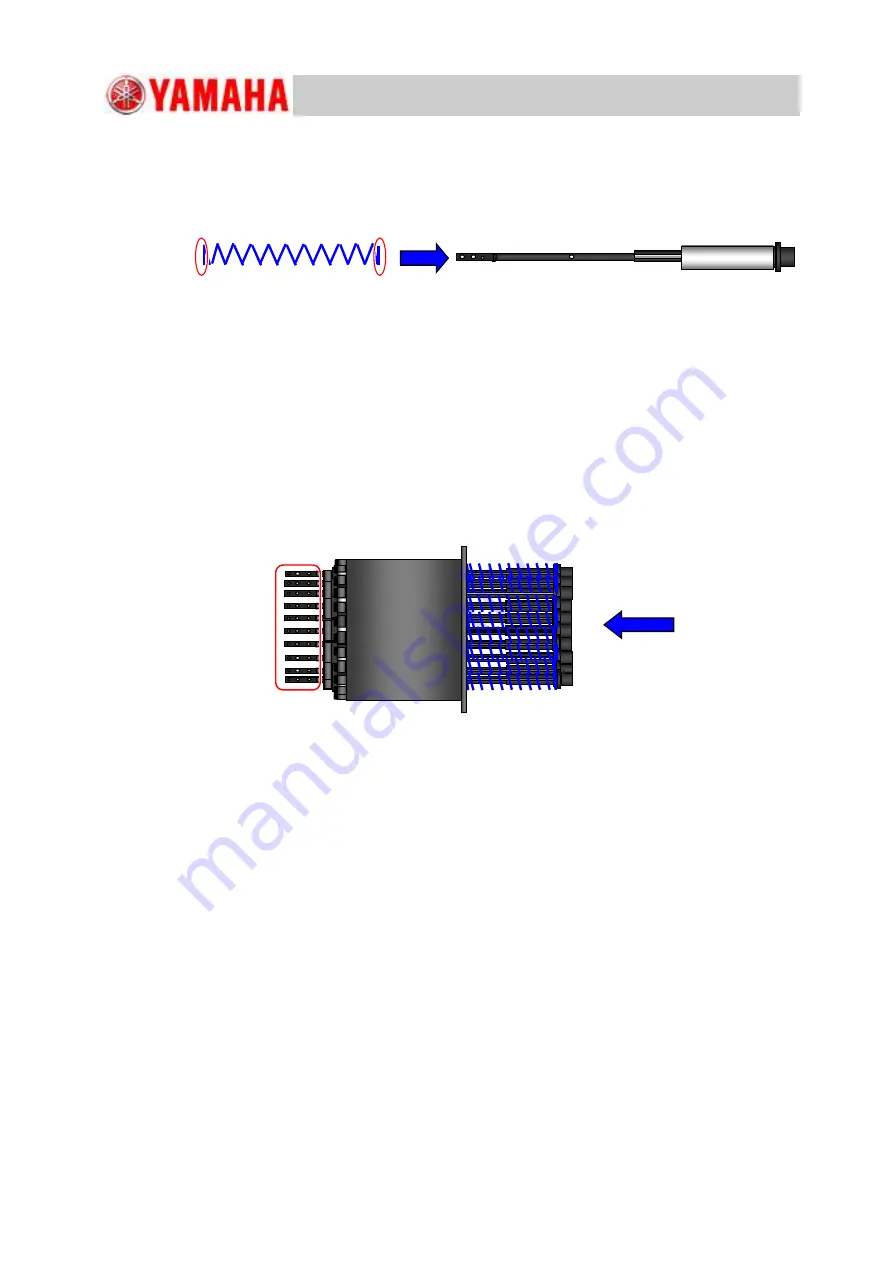

(14) Insert the nozzle shaft into the outer casing, taking care of the correct direction of the

nozzle shaft.

* Make sure that the outer casing has the same serial No. as that of the nozzle shaft.

* Do not insert the nozzle shaft forcibly.

(This is to avoid damage that might result in the damage to the V-packing or the V-

packing coming off).

* After the nozzle shaft insertion, if any excessive grease is attached to the nozzle

shaft (in the location framed in red in the following figure), wipe it out using a cloth,

etc.

(15) Then, assemble the nozzle shaft assembly using the reverse procedure of the

disassembling.

Attach the "Head Attachment Supporting Jig" to the nozzle shaft assembly using the

Large Diffusing Plate set tapped hole, as shown in the following figure.

* Unless the "Head Attachment Supporting Jig" is held securely, the M1. 6L4 bolt

might be tightened on the slant and thread might be damaged. Be careful.

* Before the attachment, confirm the No. 1 nozzle position.

(16) Clean the packing holder insertion section in the DD motor unit using a cotton

applicator, etc., dipped in alcohol.

(17) Insert the 15 packing holders into the DD motor using the "Packing Holder Insertion

Supporting Jig".

* Pay attention to the insertion direction of the packing holder.

(18) Insert the nozzle shaft assembly gently into the DD motor unit straight from the lower

side, so that no load is given to the nozzle shaft.

Apply grease onto both ends of the spring.

Fig.D79

Fig.D80