For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

20/273

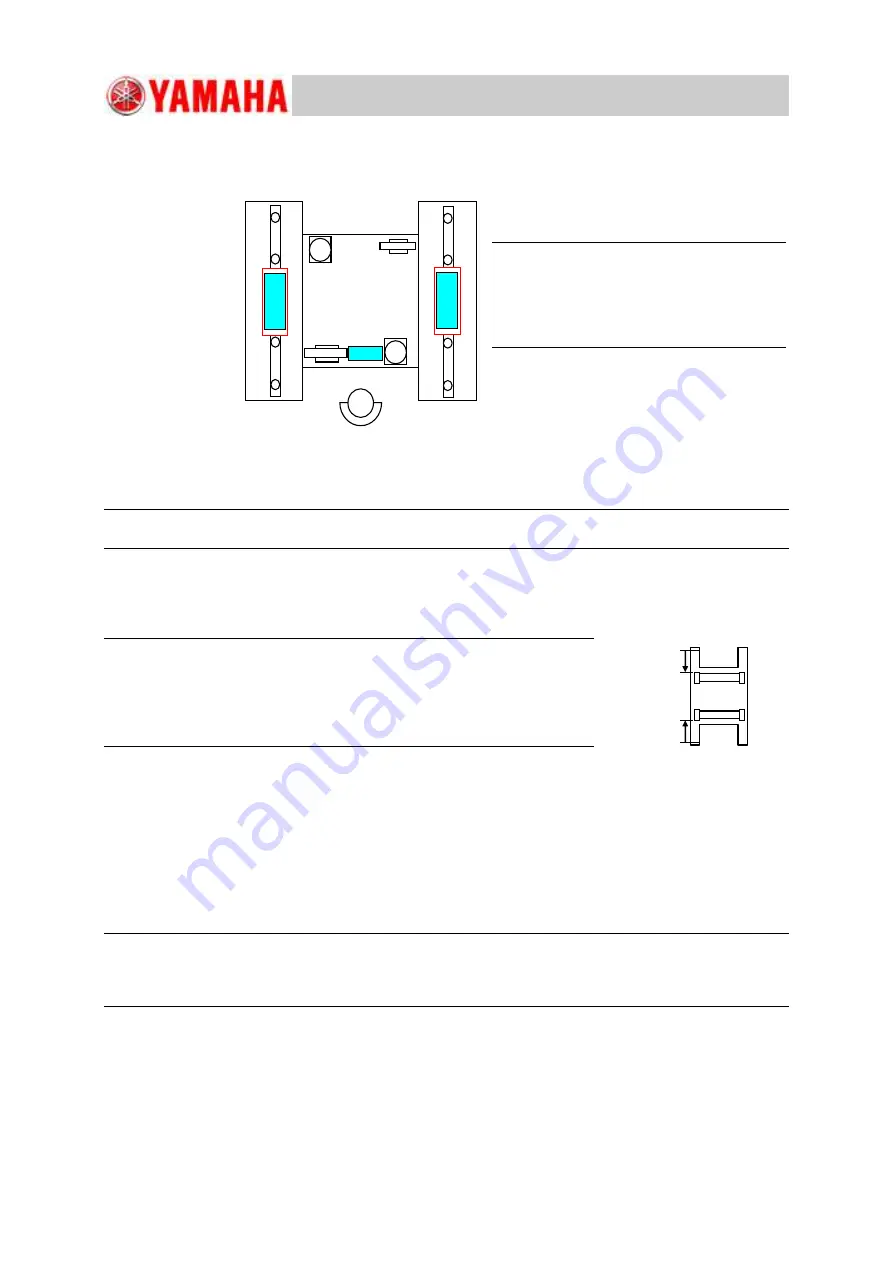

(1.2) Place the leveling instruments as shown in Fig. A14. Roughly level-adjust

(within #1 to #3 scale mark) the machine in the location close to the machine

installation place and then, place the machine temporarily.

Fig. A14

(1.3)

Using the pendulum movement, bring the machine to the installation position.

Note:

Using the "Sliding Sheet" for moving the machine close to the installation position facilitates the work.

(4)

Refer to the "Fixtures Removal Check List" adhered to the machine, and remove the

fixtures.

Note:

When the fixtures have been removed, move the Beams 1 and 2 to the

position about 450mm from the mechanical stopper. This position shall

be the basic position for the leveling adjustment. When the machine is to

be moved according to these conditions, pay particular attention to the

level vial not to drop it.

(5)

Level the machine.

(5.1)

Leveling (Refer to Fig. A16).

Direction Y: The leveling is performed using the level vials A and C.

(Standard Value: +/- one scale mark = within 2/100 mm)

Direction X : The leveling is performed using the level vial B.

(Standard Value: +/- one scale mark = within 2/100 mm)

Lock the four legs and perform the fine adjustment so that the conditions of

the level vials A, B and C, are not changed from before.

Note:

Do not adjust the level at the adjustment section using the hook spanner in the main machine frame

section (Adjustment at the above adjustment section is performed only immediately after the

assembling).

Now, the main machine installation operation is completed.

A

C

B

450 mm

450 mm

Note:

(a) The leveling instrument block jig to be

placed on the linear guide is required

(b) Confirm that the linear guide cap is

securely set (not projected).

Fig. A15