For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

44/273

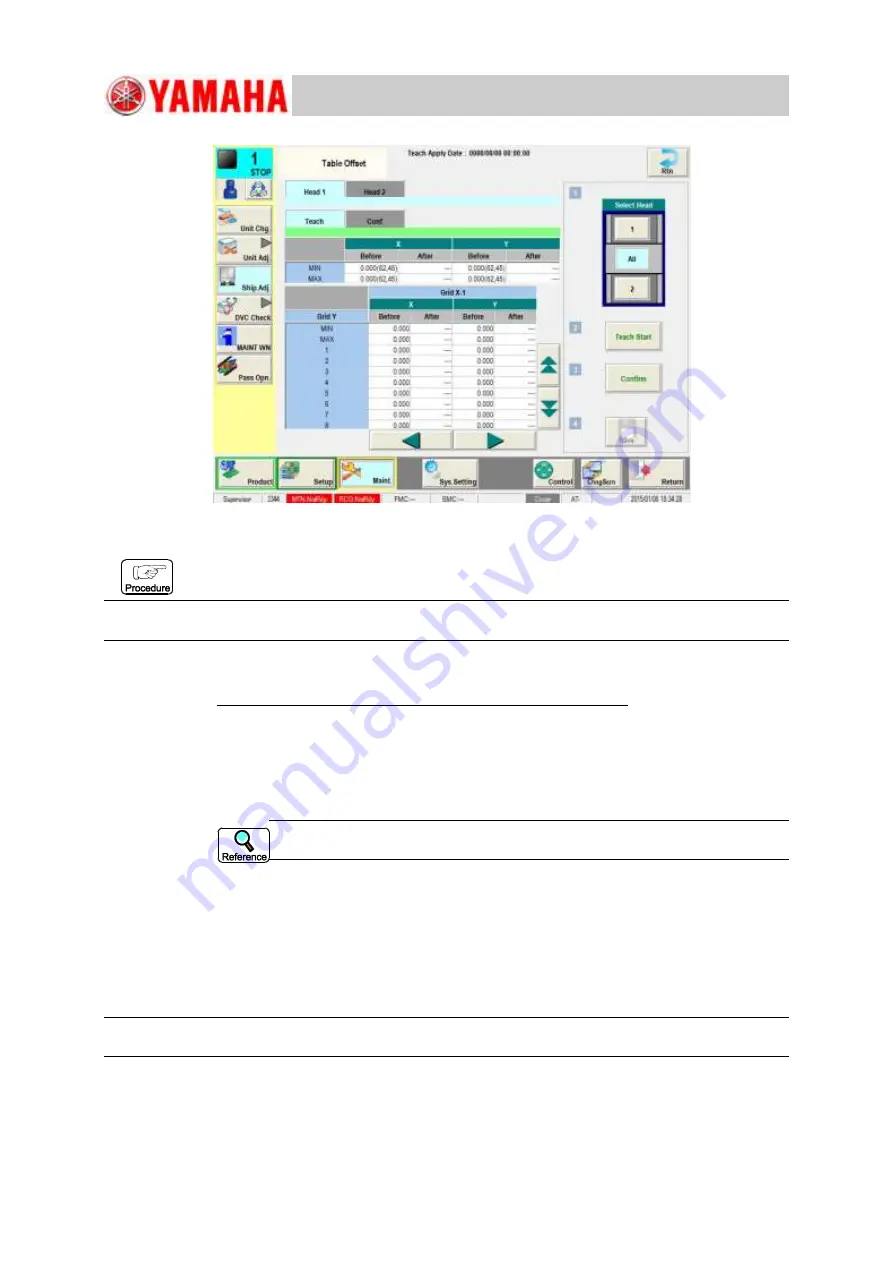

Fig. A37

Teaching Procedure

Glass Jig PCB Clamping Procedure

Note:

Unless the support jig and support pins are not removed, the glass jig PCB might be broken.

(1)

Make sure that nothing is attached on the backup table.

(2) Make sure that the PP data PCB size X is 280 mm or smaller. In the case of 280mm

or larger, change the pattern program to one for the PP data with the PCB size of

280 mm or smaller.

(3) Enable the debug mode and press the [Maint.] button in the operation window and

press the [Unit Adj.] button. Then, zero each of the "L-Conveyor", "Conveyor" and

"R-Conveyor" in the "Conveyor" tab sheet.

Refer to "Change Procedure to Debug Mode" for the procedure to transfer to

the debug mode.

(4) Perform the setting so that "619.1" is added to the SW data and "597.1" is deleted.

(5) Change the conveyor width.

Enter the value of "430" in the "Tgt Wd" text box and "0.3" in the "Clearance" text

box on the "CONVEYOR" tab sheet.

(6) Set the Z-clamp pressure to "0.1Mpa" so as not to break the glass jig PCB.

(7) Place the PEC recognition calibration jig onto the upstream side stopper position

manually.

Note:

Press the PEC recognition calibration jig reference onto the machine reference side manually.