PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

6

Battery storage

●

When the motorcycle will not be

used for a month or longer, re-

move the battery, fully charge it

and store it in a cool, dry place.

Completely recharge the battery

before reinstallation.

●

If the battery will be stored for

longer than two months, check the

specific gravity of the fluid at least

once a month and fully recharge

the battery when it is too low.

●

Always make sure the connec-

tions are correct when putting the

battery back in the motorcycle.

Make sure the breather hose is

properly connected and is not

damaged or obstructed.

EAU01307

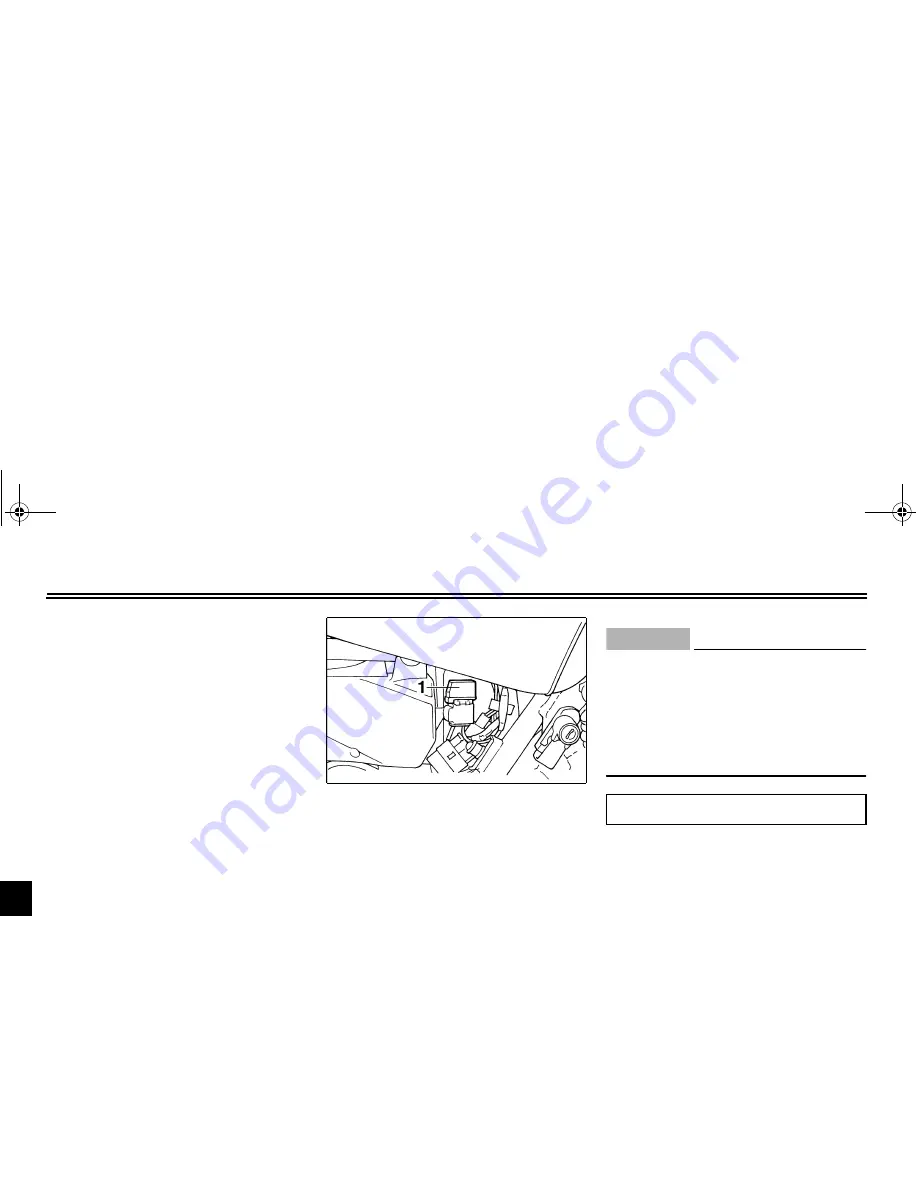

Fuse replacement

The fuse is located behind panel B.

(See page 6-5 for panel removal and

installation procedures.) If the fuse is

blown, turn off the main switch and the

switch of the circuit in question. Install a

new fuse of proper amperage. Turn on

the switches and see if the electrical

device operates. If the fuse immediate-

ly blows again, consult a Yamaha deal-

er.

EC000103

CAUTION:

@

Do not use fuses of higher amper-

age rating than those recommend-

ed. Substitution of a fuse of

improper rating can cause extensive

electrical system damage and pos-

sibly a fire.

@

1. Fuse box

Specified fuse:

20 A

E_3mw.book Page 28 Monday, February 5, 2001 9:54 AM