–53–

CYLINDER HEAD AND CYLINDER

ENG

NOTE:

If out if specification, replace piston and pis-

ton rings as a set.

3rd step:

Calculate the piston-to-cylinder clearance

with the following formula:

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

If out of specification, rebore or replace cylin-

der, and replace piston and piston rings as a

set.

Piston-to-cylinder clearance:

600: 0.065

0.070 mm

(0.0026

0.0028 in)

Limit 0.1 mm (0.004 in)

700: 0.070

0.075 mm

(0.0028

0.0030 in)

Limit 0.1 mm (0.004 in)

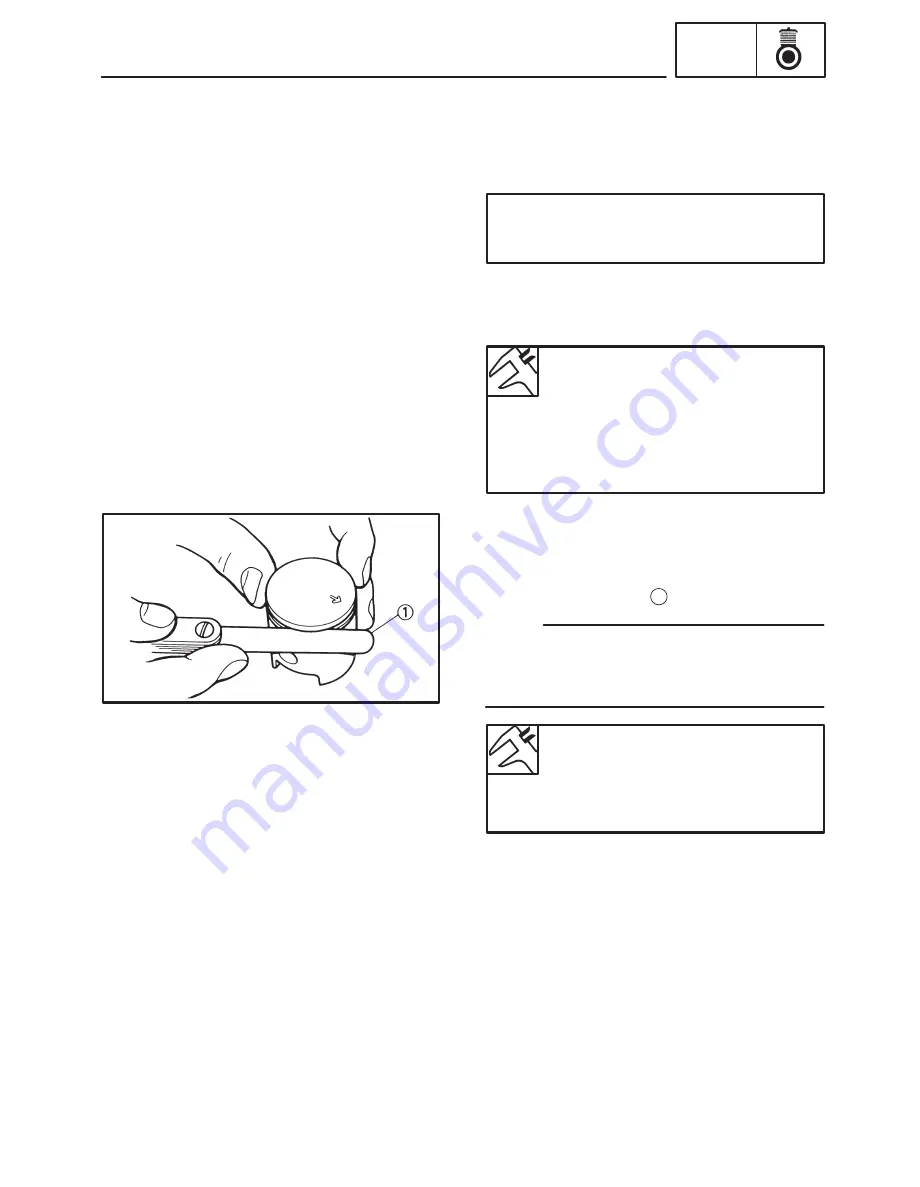

2. Measure:

Side clearance (piston rings)

Out of specification

Replace piston

and / or rings.

Use a feeler gauge

1

.

Eliminate the carbon deposits from the piston

ring grooves and rings before measuring the

side clearance.

Side clearance (600, 700)

Top: 0.02

0.06 mm

(0.0008

0.0024 in)

2nd: 0.02

0.06 mm

(0.0008

0.0024 in)

Summary of Contents for SX500D

Page 1: ...SUPPLEMENTARY SERVICE MANUAL ...

Page 85: ... 81 CABLE ROUTING SPEC CABLE ROUTING 500 ...

Page 87: ... 83 CABLE ROUTING SPEC ...

Page 89: ... 85 CABLE ROUTING SPEC ...

Page 91: ... 87 CABLE ROUTING SPEC ...

Page 93: ... 89 CABLE ROUTING SPEC ...

Page 95: ... 91 CABLE ROUTING SPEC ...

Page 97: ... 93 CABLE ROUTING SPEC CABLE ROUTING 600 700 ...

Page 99: ... 95 CABLE ROUTING SPEC ...

Page 101: ... 97 CABLE ROUTING SPEC ...

Page 103: ... 99 CABLE ROUTING SPEC ...

Page 105: ... 101 CABLE ROUTING SPEC ...

Page 107: ... 103 CABLE ROUTING SPEC ...

Page 109: ... 105 CABLE ROUTING SPEC ...

Page 112: ...WIRING DIAGRAM ...

Page 114: ...WIRING DIAGRAM ...