–59–

CARBURETORS

CARB

NOTE:

NOTE:

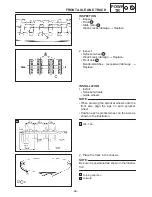

3. Install:

Return springs

1

Hook the spring hooks

2

to the projections on

the connecting lever

3

and carburetor body

4

,

while twisting the spring clockwise approxi-

mately 315 degrees.

Carburetors

FUEL LEVEL ADJUSTMENT

1. Measure:

Fuel level

a

Out of specification

Adjust.

Fuel level

a

(From the bore center):

40

42 mm (1.56

1.64 in)

Measurement and adjustment steps:

Place the machine on a level place.

Attach the fuel level gauge (90890-01312,

YM-01312-A)

1

to the float chamber nozzle.

Use the adapter (outside diameter ø6 hose)

2

when attaching the fuel level gauge.

Loosen the drain screw

3

and start the en-

gine.

Place the tube along the seam line

4

of the

carburetor body.

Measure the fuel level

a

with gauge.

If the fuel level is incorrect, adjust the fuel level.

Remove the carburetor.

Inspect the valve seat and needle valve.

If either is worn, replace them both.

If both are fine, adjust the float height by bend-

ing the float tang

5

on the float.

Recheck the fuel level.

Summary of Contents for SX500D

Page 1: ...SUPPLEMENTARY SERVICE MANUAL ...

Page 85: ... 81 CABLE ROUTING SPEC CABLE ROUTING 500 ...

Page 87: ... 83 CABLE ROUTING SPEC ...

Page 89: ... 85 CABLE ROUTING SPEC ...

Page 91: ... 87 CABLE ROUTING SPEC ...

Page 93: ... 89 CABLE ROUTING SPEC ...

Page 95: ... 91 CABLE ROUTING SPEC ...

Page 97: ... 93 CABLE ROUTING SPEC CABLE ROUTING 600 700 ...

Page 99: ... 95 CABLE ROUTING SPEC ...

Page 101: ... 97 CABLE ROUTING SPEC ...

Page 103: ... 99 CABLE ROUTING SPEC ...

Page 105: ... 101 CABLE ROUTING SPEC ...

Page 107: ... 103 CABLE ROUTING SPEC ...

Page 109: ... 105 CABLE ROUTING SPEC ...

Page 112: ...WIRING DIAGRAM ...

Page 114: ...WIRING DIAGRAM ...