8-18

ESU00180

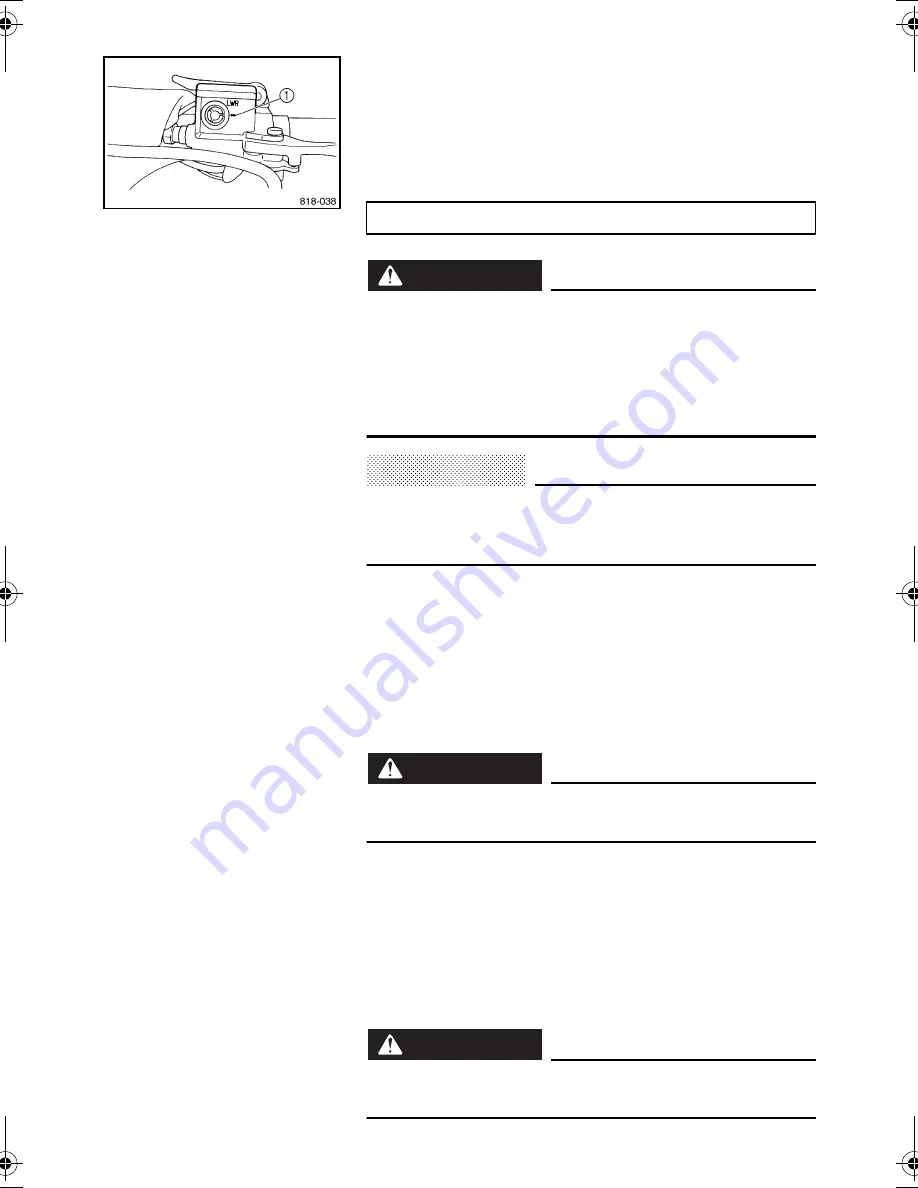

Checking the brake fluid level

Place the snowmobile on a level surface. Check that the

brake fluid is above the lower level and replenish when

necessary.

1

Lower level

WARNING

@

Be careful that water does not enter the master cylin-

der when refilling. Water will significantly lower the

boiling point of the fluid and may result in vapor

lock.

If the brake fluid level goes down, consult a Yamaha

dealer.

@

CAUTION:

@

Brake fluid may deteriorate painted surfaces or plas-

tic parts. Never spill any fluid. If any is spilled, clean

it up immediately.

@

ESU00181

Brake fluid replacement

Brake fluid replacement is necessary when the following

components are replaced during the periodic mainte-

nance or if they are damaged or leaking.

a. All oil seals of the master cylinder and caliper cylinder

b. The brake hose

WARNING

@

Make sure that the brake fluid and the above parts

are replaced by a Yamaha dealer.

@

ESU00183

Suspension

The suspension can be adjusted to suit rider preference.

A softer setting, for example, may provide greater rider

comfort, while a harder setting may allow more precise

handling and control over certain types of terrain or riding

conditions.

WARNING

@

Be sure to have a Yamaha dealer make this adjust-

ment.

@

Specified brake fluid: DOT 4

U8EK11.book Page 18 Thursday, April 25, 2002 5:10 PM

Summary of Contents for SXV70H

Page 1: ...OWNER S MANUAL SNOWMOBILE SXV70H SXV70ERH SXV70MH 8EK 28199 11 LIT 12628 02 27 ...

Page 2: ......

Page 8: ...1 1 ESU00004 1 YAMAHA MOTOR CORPORATION U S A SNOWMOBILE LIMITED WARRANTY CW 01E ...

Page 9: ...1 2 CW 02E ...

Page 10: ...1 3 CW 03E ...

Page 11: ...1 4 ESU00005 YAMAHA EXTENDED SERVICE Y E S CW 10E ...

Page 13: ...2 2 4 SXV70M 5 SXV70M 6 SXV70M ...

Page 17: ... MEMO ...

Page 93: ... MEMO ...

Page 96: ... MEMO ...

Page 97: ......

Page 98: ...PRINTED ON RECYCLED PAPER PRINTED IN JAPAN 2002 04 2 6 2 CR E YAMAHA MOTOR CO LTD ...