4-24

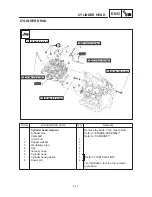

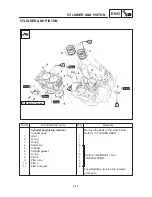

CYLINDER AND PISTON

ENG

NOTE:

CAUTION:

NOTE:

REMOVAL

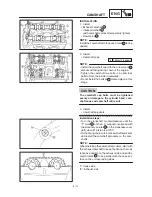

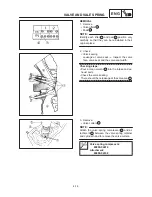

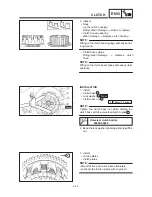

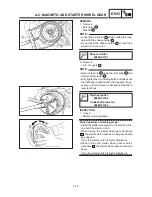

1. Remove:

Piston circlips 1

Piston pins 2

Pistons 3

Before removing the piston pin clip, cover the

crankcase with a clean rag to prevent the piston

pin clip from falling into the crankcase cavity.

Put identification marks on each piston head for

reference during reinstallation.

Before removing the piston pin, deburr the clip

groove and pin hole area. If the piston pin groove

is deburred and piston pin is still difficult to re-

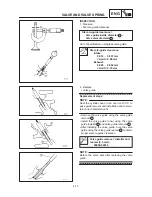

move, use the piston pin puller 4 .

Piston pin puller:

90890-01304

Do not use a hammer to drive the piston pin

out.

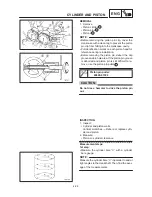

INSPECTION

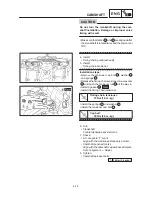

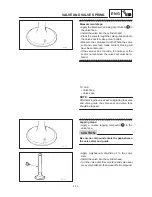

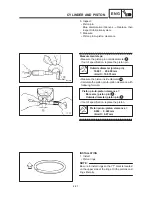

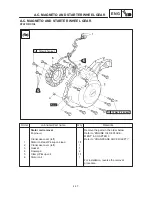

1. Inspect:

Cylinder and piston walls

Vertical scratches

Rebore or replace cylin-

der and piston.

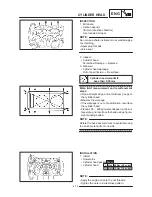

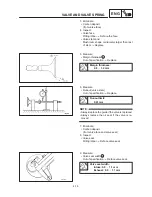

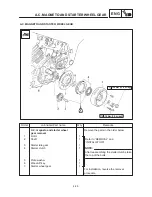

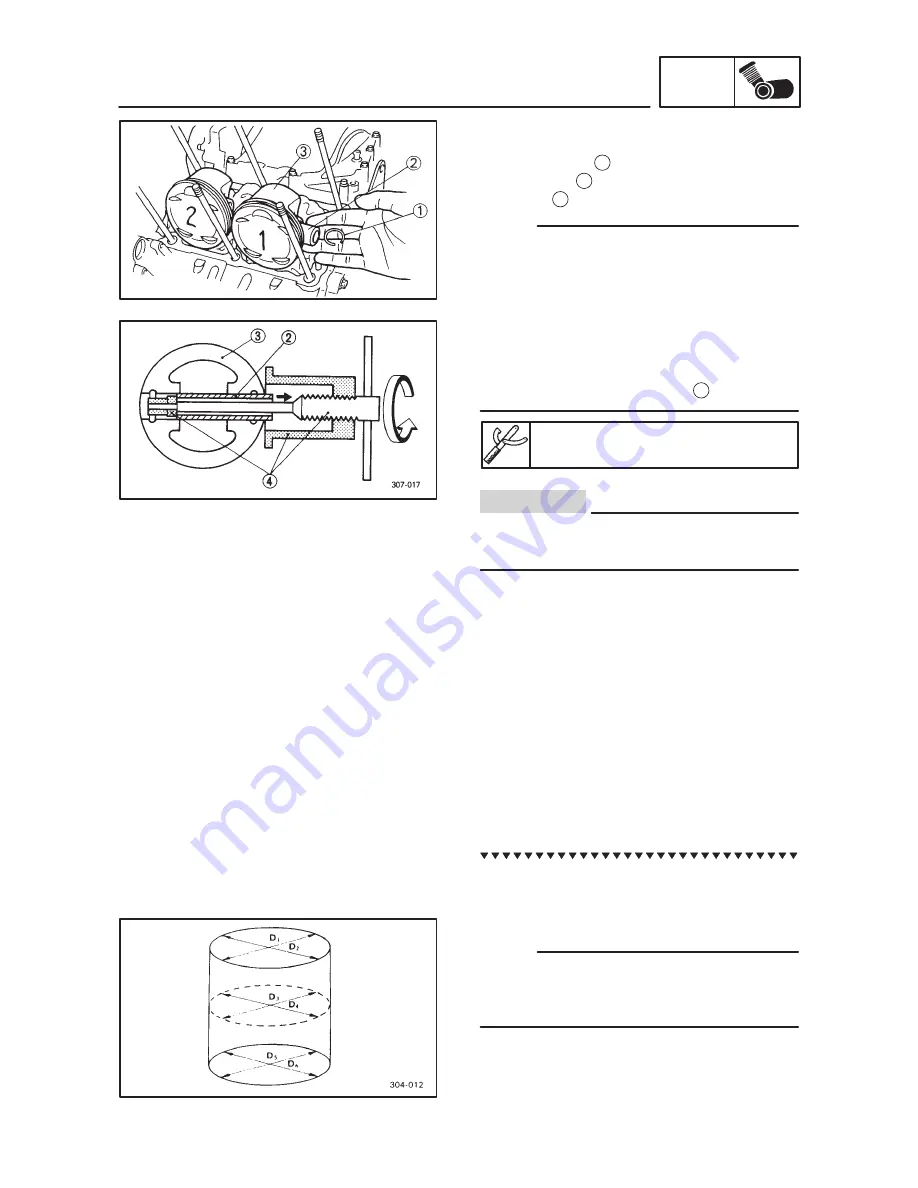

2. Measure:

Piston-to-cylinder clearance

Measurement steps:

1st step:

Measure the cylinder bore “C” with a cylinder

bore gauge.

Measure the cylinder bore “C” in parallel to and at

right angles to the crankshaft. Then, find the aver-

age of the measurements.

Summary of Contents for TDM850 1996

Page 1: ......

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 20: ...SPEC 2 ...

Page 22: ...SPEC ...

Page 45: ...2 23 LUBRICATION DIAGRAMS SPEC 1 Cylinder head 2 Rear balancer 3 Crankshaft 4 Drain bolt ...

Page 46: ...2 24 LUBRICATION DIAGRAMS SPEC 1 Main axle 2 Drive axle ...

Page 56: ...SPEC ...

Page 57: ...INSP ADJ 3 ...

Page 121: ...INSP ADJ ...

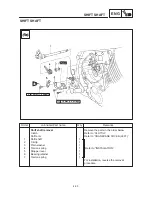

Page 122: ...ENG 4 ...

Page 192: ...ENG ...

Page 193: ...COOL 5 ...

Page 195: ...COOL ...

Page 204: ...CARB 6 ...

Page 206: ...CARB ...

Page 214: ...CARB ...

Page 215: ...CHAS 7 ...

Page 273: ...CHAS ...

Page 274: ...ELEC 8 ...

Page 276: ...ELEC ...

Page 306: ...8 30 LIGHTING SYSTEM ELEC ...

Page 307: ...8 31 SIGNAL SYSTEM ELEC SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 322: ...ELEC ...

Page 323: ...TRBL SHTG 9 ...

Page 325: ...TRBL SHTG ...