INSP

ADJ

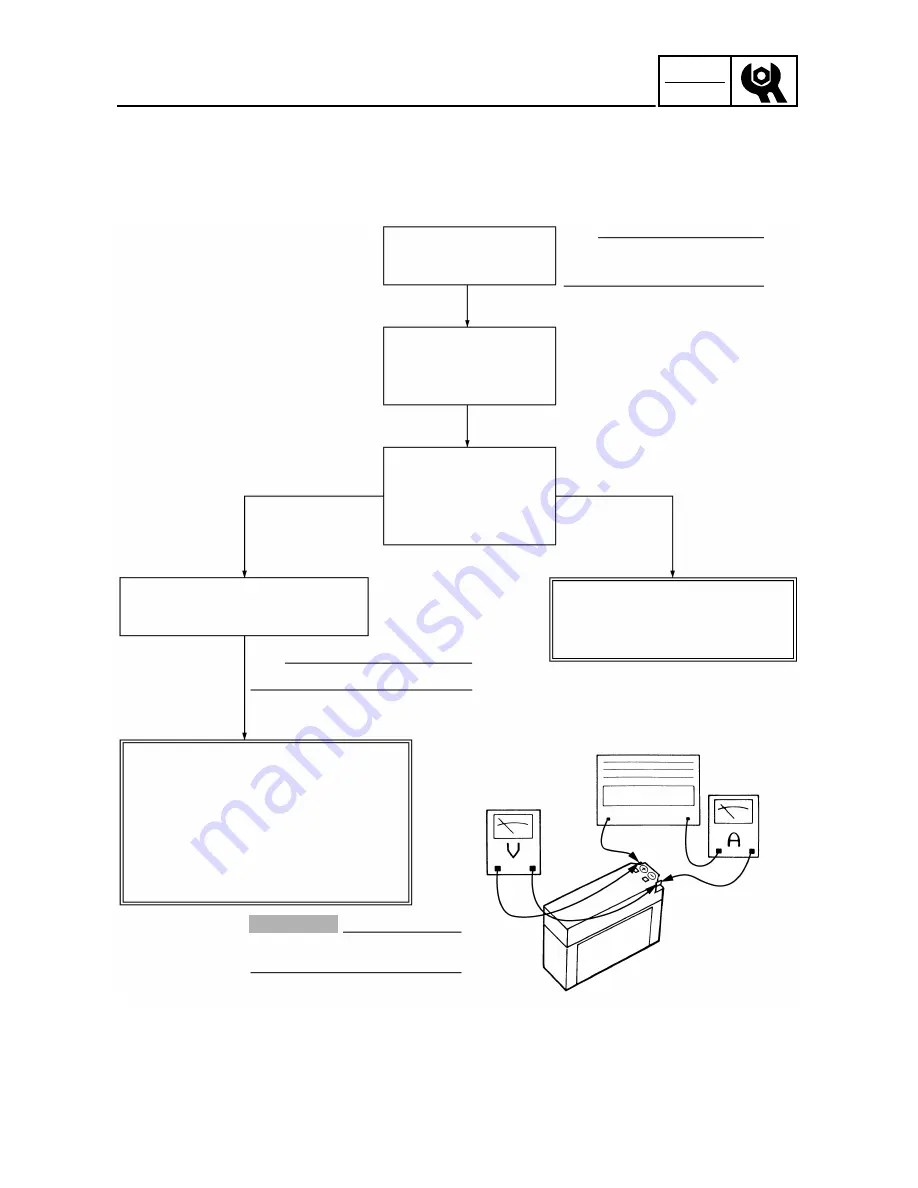

CONTROLE ET RECHARGE DE LA BATTERIE (TT-R90E)

Méthode de charge à l’aide d’un chargeur à tension constante

Mesurer la tension en circuit

ouvert avant de charger.

Connecter un chargeur et un

ampèremètre à la batterie et

lancer la charge.

L’ampérage est-il supérieur

à l’ampérage standard de

charge indiqué sur la batte-

rie ?

Recharger la batterie jusqu’à ce que la

tension de charge atteigne 15 V.

N.B.:

Régler le temps de charge pour un maximum de

20 heures.

Laisser reposer la batterie pendant 30 minutes

avant de mesurer sa tension en circuit ouvert.

12,8 V

→

La charge est terminée.

12,0 à 12,7 V

→

Il est nécessaire de recharger.

Moins de 12,0 V

→

Changer la batterie.

Les chargeurs à ampérage constant ne convien-

nent pas pour recharger les batteries MF.

Ce type de chargeur ne permet pas de

charger une batterie MF. Il est recom-

mandé d’utiliser un chargeur à tension

variable.

N.B.:

Laisser reposer la batterie pendant

30 minutes avant de mesurer sa tension

en circuit ouvert.

Chargeur

Ampèremètre

Voltmètre

OUI

NON

ATTENTION:

3 - 26

Summary of Contents for TT-R90(T)

Page 45: ...GEN INFO MEMO...

Page 57: ...GEN INFO MEMO...

Page 109: ...SPEC MEMO...

Page 319: ...ELEC MEMO...

Page 331: ...ELEC MEMO...

Page 347: ...ELEC MEMO...

Page 353: ...ELEC MEMO...

Page 363: ......