PERIODIC MAINTENANCE AND MINOR REPAIR

6-31

6

that the breather hose is properly

routed, in good condition, and not

obstructed.

CAUTION:

ECA10600

If the breather hose is positioned in

such a way that the frame is ex-

posed to electrolyte or gas expelled

from the battery, the frame could

suffer structural and external dam-

ages.

EAU23600

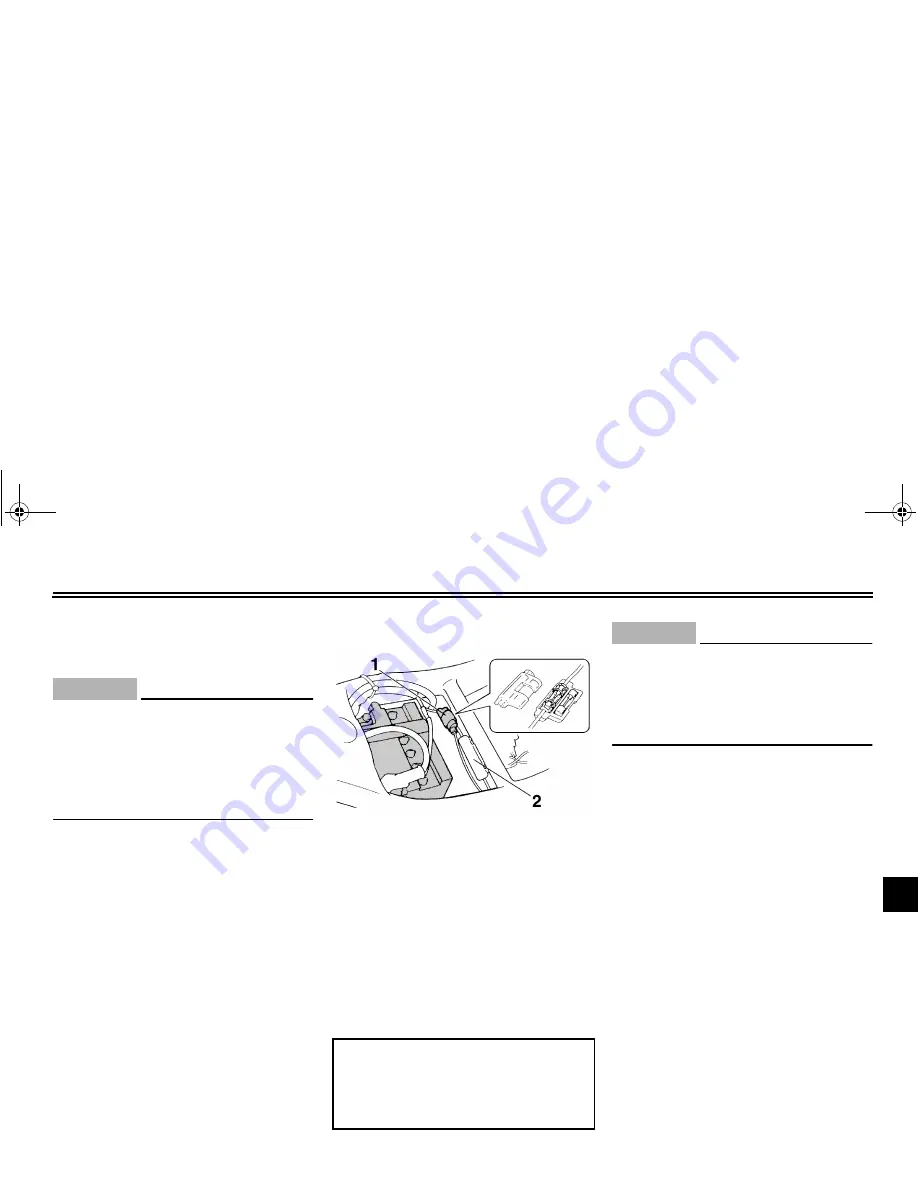

Replacing the fuses

The main fuse and the signaling sys-

tem fuse holders are located under the

rider seat. (See page 3-8.)

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage.

CAUTION:

ECA10640

Do not use a fuse of a higher amper-

age rating than recommended to

avoid causing extensive damage to

the electrical system and possibly a

fire.

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows

again, have a Yamaha dealer

check the electrical system.

1. Main fuse

2. Signaling system fuse

Specified fuses:

Main fuse:

20.0 A

Signaling system fuse:

10.0 A

U2UJ1DE0.book Page 31 Thursday, May 13, 2004 11:59 PM

Summary of Contents for VIRAGO XV250T

Page 1: ...2UJ 28199 1D LIT 11626 18 21 XV250T XV250TC OWNER S MANUAL ...

Page 2: ...EAU10041 U2UJ1DE0 book Page 1 Thursday May 13 2004 11 59 PM ...

Page 90: ...CONSUMER INFORMATION 9 8 9 U2UJ1DE0 book Page 8 Thursday May 13 2004 11 59 PM ...

Page 95: ...PRINTED IN JAPAN 2004 05 0 6 1 CR E PRINTED ON RECYCLED PAPER YAMAHA MOTOR CO LTD ...