PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

6

EAU02939

Checking the front fork

The condition and operation of the front

fork must be checked as follows at the

intervals specified in the periodic main-

tenance and lubrication chart.

To check the condition

EW000115

WARNING

@

Securely support the motorcycle so

that there is no danger of it falling

over.

@

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation

1. Place the motorcycle on a level

surface and hold it in an upright

position.

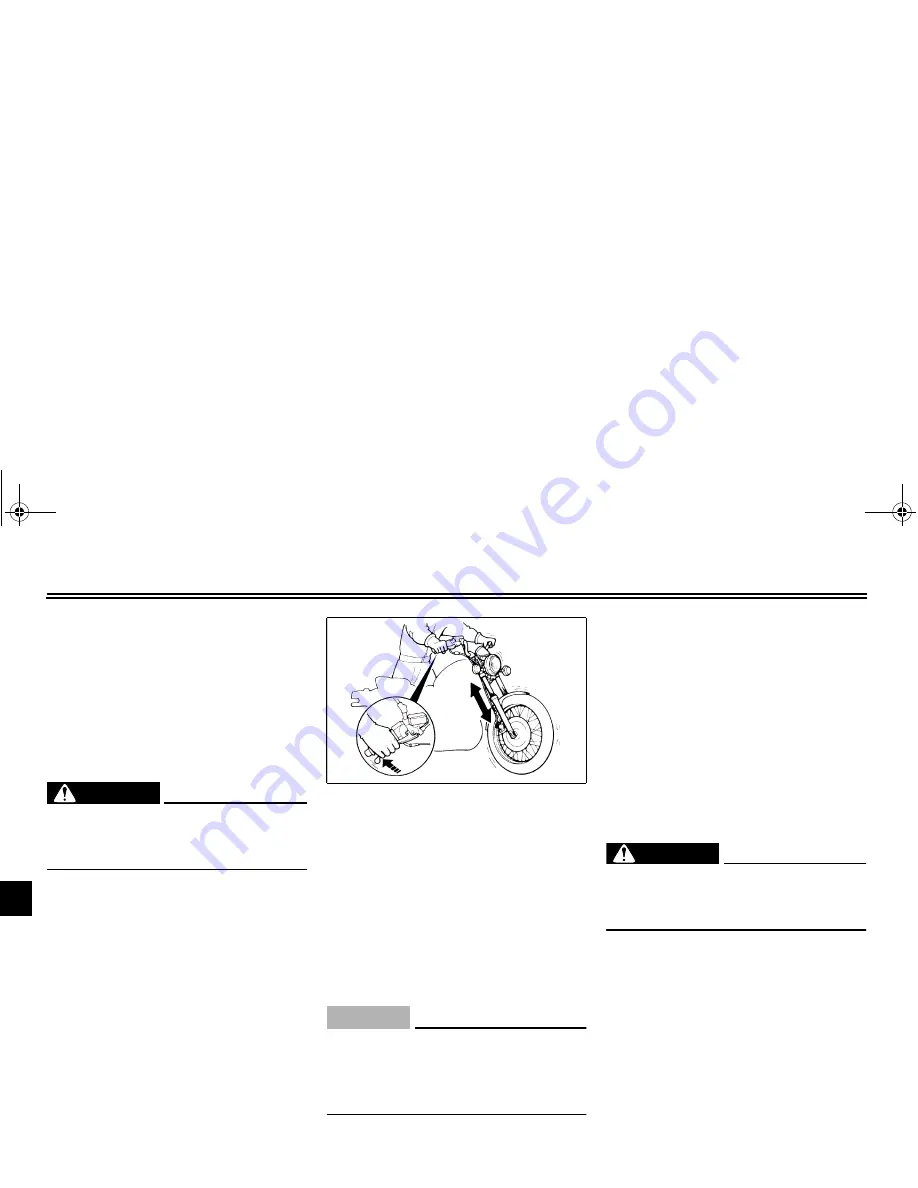

2. While applying the front brake,

push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

EC000098

CAUTION:

@

If any damage is found or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

@

EAU00794

Checking the steering

Worn or loose steering bearings may

cause danger. Therefore, the operation

of the steering must be checked as fol-

lows at the intervals specified in the pe-

riodic maintenance and lubrication

chart.

1. Place a stand under the engine to

raise the front wheel off the

ground.

EW000115

WARNING

@

Securely support the motorcycle so

that there is no danger of it falling

over.

@

E_3bt.book Page 27 Thursday, September 7, 2000 10:01 AM

Summary of Contents for Virago XV535

Page 1: ...3BT 28199 E7 OWNER S MANUAL XV535 ...

Page 2: ...H_5KS_Toc0 fm Page 2 Monday August 21 2000 11 11 AM ...

Page 8: ...E_3bt book Page 2 Thursday September 7 2000 10 01 AM ...

Page 30: ...E_3bt book Page 3 Thursday September 7 2000 10 01 AM ...

Page 76: ...E_3bt book Page 39 Thursday September 7 2000 10 01 AM ...

Page 94: ...H_5KS_Toc0 fm Page 2 Monday August 21 2000 11 11 AM ...

Page 95: ...H_5KS_Toc0 fm Page 2 Monday August 21 2000 11 11 AM ...

Page 96: ...PRINTED IN JAPAN 2000 7 0 2 1 CR E PRINTED ON RECYCLED PAPER YAMAHA MOTOR CO LTD ...