4 - 81

ENG

CONNECTING RODS AND PISTONS

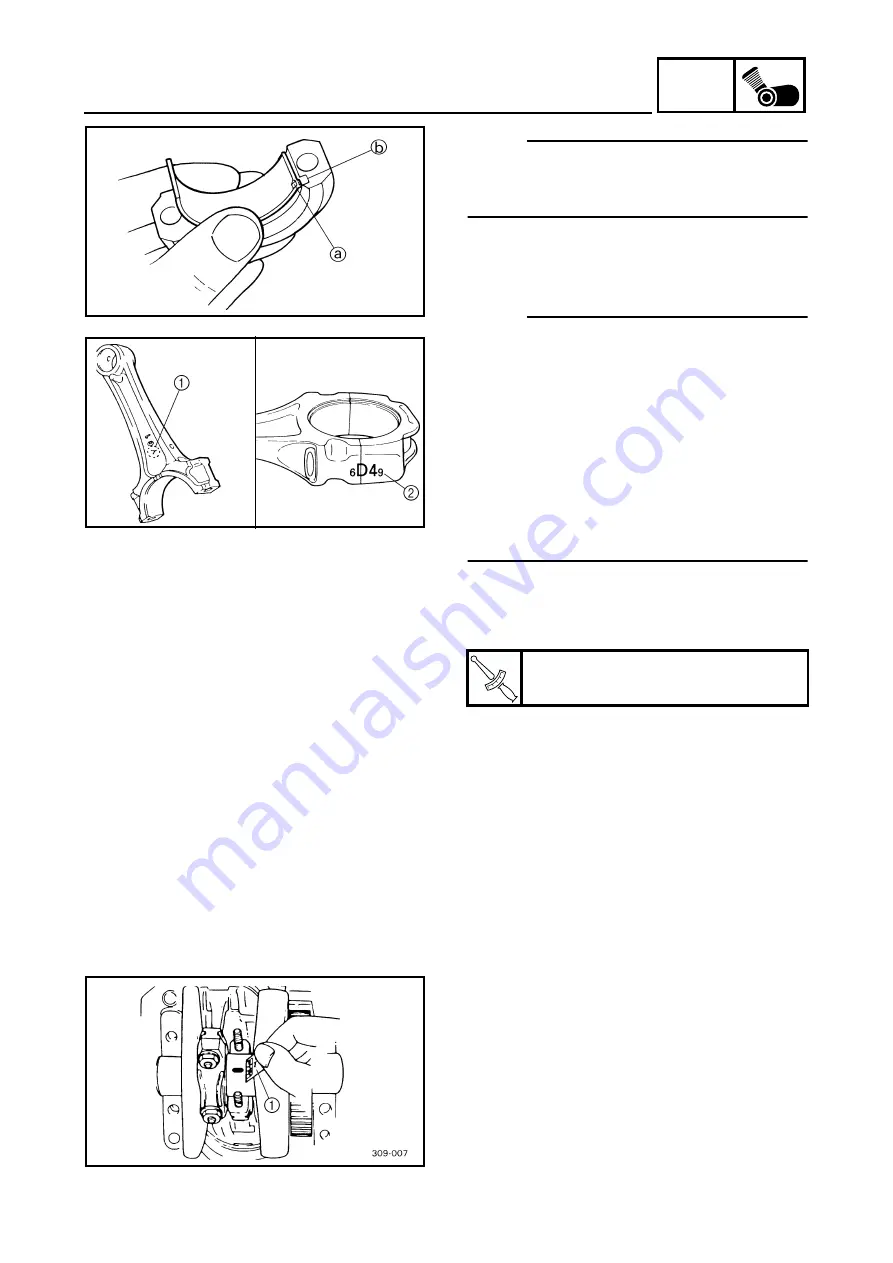

NOTE:

@

Align the projections

a

on the big end bear-

ings with the notches

b

in the connecting rod

and connecting rod cap.

@

c. Put a piece of Plastigauge

®

on the crank-

shaft pin.

d. Assemble the connecting rod halves.

NOTE:

@

• Do not move the connecting rod or crank-

shaft until the clearance measurement has

been completed.

• Lubricate the bolts threads and nut seats

with molybdenum disulfide grease.

• Make sure the “Y” mark

1

on the connecting

rod faces towards the left side of the crank-

shaft.

• Make sure the characters

2

on both the con-

necting rod and connecting rod cap are

aligned.

@

e. Tighten the connecting rod nuts.

Refer to “INSTALLING THE PISTONS AND

CYLINDERS”.

f. Remove the connecting rod and big end

bearings.

Refer to “REMOVING THE CONNECTING

RODS AND PISTONS”.

T

R

.

.

Connecting rod nut

36 Nm (3.6 m • kg)

g. Measure the compressed Plastigauge

®

width

1

on the crankshaft pin. If the crank-

shaft-pin-to-big-end-bearing clearance is

out of specification, select replacement big

end bearings.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Summary of Contents for VMX12 2001

Page 1: ...VMX12 2001 3LRD AE1 SERVICEMANUAL ...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1 ...

Page 11: ...GEN INFO ...

Page 21: ......

Page 22: ...SPEC 2 ...

Page 24: ...SPEC ...

Page 52: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Camshaft 2 Main gallery 3 Crankshaft 4 Oil level switch ...

Page 54: ...2 30 SPEC OIL FLOW DIAGRAMS 1 Crankshaft 2 Oil pipe 3 Oil filter ...

Page 65: ...CHK ADJ 3 ...

Page 125: ......

Page 126: ...ENG 4 ...

Page 130: ...ENG ...

Page 236: ......

Page 237: ...COOL 5 ...

Page 239: ...COOL ...

Page 258: ...CARB 6 ...

Page 260: ...CARB ...

Page 272: ......

Page 273: ...CHAS 7 ...

Page 389: ......

Page 390: ...ELEC 8 ...

Page 396: ...8 4 ELEC SWITCHES ...

Page 417: ...8 25 ELEC STARTER MOTOR 3 Install O rings 1 bolts 2 New T R 5 Nm 0 5 m kg ...

Page 445: ...TRBL SHTG 9 ...