/---

INSPECTION AND REPAIR

the bearings, crank pins and bear-

ing portions of the connecting rods.

the upper half of the bearing into

the connecting rod and lower half of the

bearing into the connecting rod cap.

NOTE:

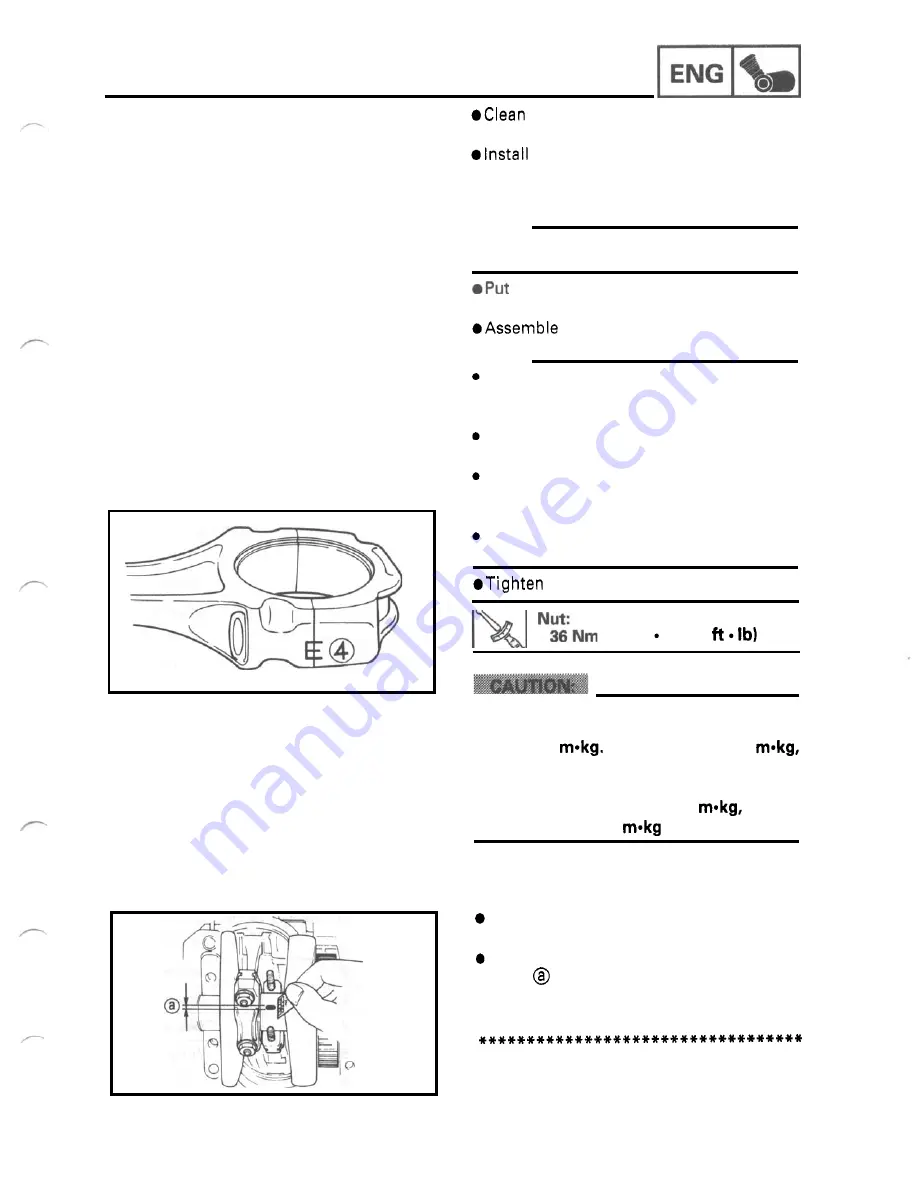

Align the projection of the bearing with the

notch of the cap and connecting rod.

a

piece of Plastigauge® on the crank

the connecting rod halves.

pin.

NOTE:

Do not move the connecting rod or crank-

shaft until the oil clearance measurement

has been completed.

Apply molybdenum disulfide grease

to

the bolts, threads and nut seats.

Make sure the "Y" marks on the connect-

ing rods face the left side of the crank-

shaft.

Make sure that the letters on both compo-

nents align to from

a

perfect character.

the nuts.

(3.6 m kg,

25

I

Tighten to full torque specificationwithout

pausing. Apply continuous torque between

3.0

and

3.8

Once you reach 3.0

DO NOT STOP TIGHTENING until final

torque is reached. If tightening is inter-

rupted between 3.0 and 3.8

loosen

nut to lessthan 3.0

and start again.

Remove

the

connecting rods and bear-

ings.

Measure the compressed Plastigauge®

width

on each crank pin.

If oil clearance is out of specification,

select

a

replacement bearing.

- 9 -

Summary of Contents for VMX12H

Page 1: ...VMXl2N NC K KC...

Page 2: ...LIT 11616 10 12...

Page 22: ...VAMAHA MOTOR CO LTD PRINTEDI N U S A...

Page 23: ...E LIT 11616 08 77...

Page 44: ...CIRCUIT DIAGRAM ELECTRICAL CIRCUIT DIAGRAM I I 1...

Page 48: ...VAMAHA MOTOR CO LTD PRINTED IN U S A...

Page 49: ...I LIT I1616 06 08...

Page 56: ...TO IWATA JAPAN PRINTED IN U S A...

Page 57: ...LIT 1...

Page 64: ...IWATA JAPAN PRINTED IN U S A...

Page 65: ...I Serr ice L 1616 04 67...

Page 206: ...ENGINE ASSEMBLY AND ADJUSTMENT MEMO 3 82...

Page 304: ...CIRCUIT DIAGRAM I I ELECTRICAL CIRCUIT DIAGRAM w w 7 1...

Page 308: ...ELECTRIC STARTING SYSTEM I I ELECTRIC STARTING SYSTEM CIRCUIT DIAGRAM 7 5...

Page 320: ...CHARGING SYSTEM CHARGING SYSTEM CIRCUIT DIAGRAM 7 17...

Page 325: ...MEMO 7 22...

Page 326: ...IGNITION SYSTEM IGNITION SYSTEM CIRCUIT DIAGRAM 7 23...

Page 334: ...LIGHTING SYSTEM LIGHTING SYSTEM CIRCUIT DIAGRAM 7 31...

Page 339: ...MEMO 7 36...

Page 340: ...SIGNAL SYSTEM SIGNAL SYSTEM CIRCUIT DIAGRAM 7 37...

Page 348: ...COOLING SYSTEM COOLING SYSTEM CIRCUIT DIAGRAM 7 45...

Page 354: ...FUEL PUMP SYSTEM FUEL PUMP SYSTEM CIRCUIT DIAGRAM 7 51...

Page 362: ...V BO O ST SYSTEM V BO O ST SYSTEM CI RCUI T DI AG RAM...

Page 390: ...LUBRICATION DIAGRAMS LUBRICATION AGRAMS LUBRICATION DIAGRAM 8 20...

Page 391: ...LUBRICATION DIAGRAMS LUBRICATION DIAGRAM 2 8 21...

Page 392: ...LUBRICATION AGRAMS LUBRICATION DIAGRAM 8 22...

Page 393: ...LUBRICATION DIAGRAMS LUBRICATION DIAGRAM 4...

Page 401: ...CABLE ROUTING CANISTER PIPE ROUTING To carburetor To fuel tank TO Canister...

Page 403: ...m...