5-82

E

POWR

1

2

3

4

5

6

7

8

9

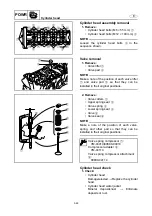

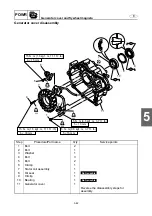

Generator cover disassembly

Step

Procedure/Part name

Q

’

ty

Service points

1

Bolt

2

2

Bolt

1

3

Washer

1

4

Bolt

3

5

Bolt

2

6

Clamp

1

7

Stator coil assembly

1

8

Oil seal

1

Not reusable

9

Circlip

1

10

Bearing

1

Not reusable

11

Generator cover

1

Reverse the disassembly steps for

assembly.

8

9

10

11

3

2

1

7

4

6

5

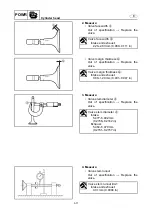

LT

242

A

A

A

A

E

LT

242

15 N

·

m (1.5 kgf

·

m, 11.1 ft

·

lb)

6

×

15 mm

5 N

·

m (0.5 kgf

·

m, 3.7 ft

·

Ib)

5

×

15 mm

LT

242

5 N

·

m (0.5 kgf

·

m, 3.7 ft

·

Ib)

5

×

10 mm

15 N

·

m (1.5 kgf

·

m, 11.1 ft

·

lb)

6

×

30 mm

LT

242

EP

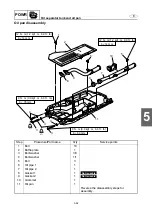

Summary of Contents for WaveRunner FX SHO

Page 1: ...SERVICE MANUAL FX SHO WaveRunner F1W 28197 1K 11 FX Cruiser SHO LIT 18616 03 12 LIT186160312 ...

Page 58: ...1 53 E GEN INFO MEMO Technical tips ...

Page 82: ...2 23 E SPEC MEMO Cable and hose routing ...

Page 110: ...3 27 E CHK ADJ MEMO General ...

Page 243: ...5 118 E POWR 1 2 3 4 5 6 7 8 9 MEMO Cooling water ...

Page 275: ...6 30 E JET PUMP 1 2 3 4 5 6 7 8 9 MEMO Intermediate housing ...

Page 353: ...E ELEC 1 2 3 4 5 6 7 8 9 7 76 MEMO Indication system ...

Page 410: ...8 55 E HULL HOOD MEMO Deck and hull ...

Page 429: ...9 18 E TRBL ANLS 1 2 3 4 5 6 7 8 9 MEMO Engine unit trouble analysis ...

Page 431: ......

Page 432: ...YAMAHA MOTOR CORPORATION USA Printed in USA Jan 2008 0 0 1 CR E ...