5-59

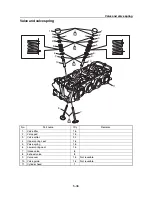

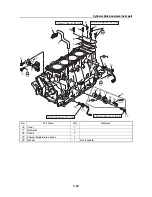

Generator cover

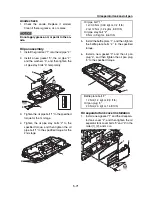

3.

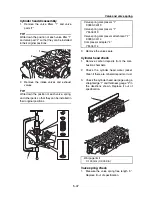

Hold the flywheel magneto “1” using the

special service tools “2” and “3”, and then

loosen the special nut “4”.

TIP:

• Loosen the special nut “4” until it can no lon-

ger be turned.

• Use a hexagon bit socket “5” with a length of

150 mm (5.91 in) or more and a width across

flats of 12 mm.

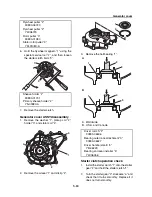

4.

Hold the flywheel magneto “1” using the

special service tools “2” and “3”, and then

remove the transfer shaft “4” using the

special service tool “5”.

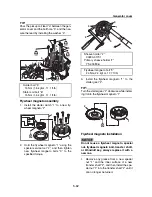

5.

Remove the flywheel magneto “1” and

Woodruff key using the special service

tools “2” and “3”.

Shaft holder “2”

90890-06721

Shaft holder “2”

YW-06721

Drive handle “3”

90890-06722

Drive handle “3”

YW-06722

4

3

2

2

1

1

5

5

Shaft holder “2”

90890-06721

Shaft holder “2”

YW-06721

Drive handle “3”

90890-06722

Drive handle “3”

YW-06722

Crankshaft holder “5”

90890-06732

Crankshaft holder “5”

YW-06562

3

2

2

1

1

5

5

4

4

2

1

3

Summary of Contents for Waverunner VXS VX1800

Page 1: ...SERVICE MANUAL WaveRunner VXS VX1800 F2W VXR VX1800A F2W F2W 28197 ZU 11 ...

Page 12: ...How to use this manual 1 7 UP Upside YDIS Yamaha Diagnostic System Abbreviation Description ...

Page 40: ...Technical tips 1 35 MEMO ...

Page 163: ...Oil separator tank and oil pan 5 72 3 4 4 4 4 4 9 4 1 5 6 10 11 7 2 3 8 ...

Page 180: ...Crankcase connecting rod and piston 5 89 MEMO ...

Page 204: ...6 23 Intermediate housing Intermediate housing bolt 2 17 Nm 1 7 kgf m 12 5 ft lb 1 2 3 ...

Page 205: ...Intermediate housing 6 24 MEMO ...

Page 251: ...Indication system 7 44 MEMO ...

Page 278: ...8 25 Exhaust system 6 Install the band Rubber hose clamp 2 3 5 Nm 0 35 kgf m 2 58 ft lb ...

Page 290: ...Deck and hull 8 37 MEMO ...

Page 312: ...Engine unit troubleshooting 9 21 MEMO ...

Page 313: ...A Appendix Wiring diagram A 1 How to use the wiring diagram A 1 VXS VXR A 2 ...

Page 317: ......

Page 318: ...Mar 2015 CR E ...