EAA01024

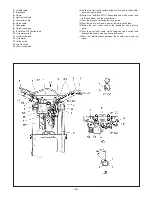

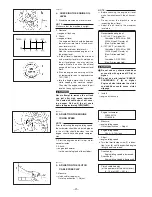

F. ADJUSTING THE FRONT

BRAKE

1. Measure:

D

brake lever position (a)

(distance (a) from the throttle grip to

the brake lever)

Out of specification

>

Adjust.

Brake lever position

(distance (a) from the throttle grip

to the brake lever)

Standard position:

95 mm (3.74 in)

Extent of adjustment:

76 ~ 97 mm (2.99 ~ 3.82 in)

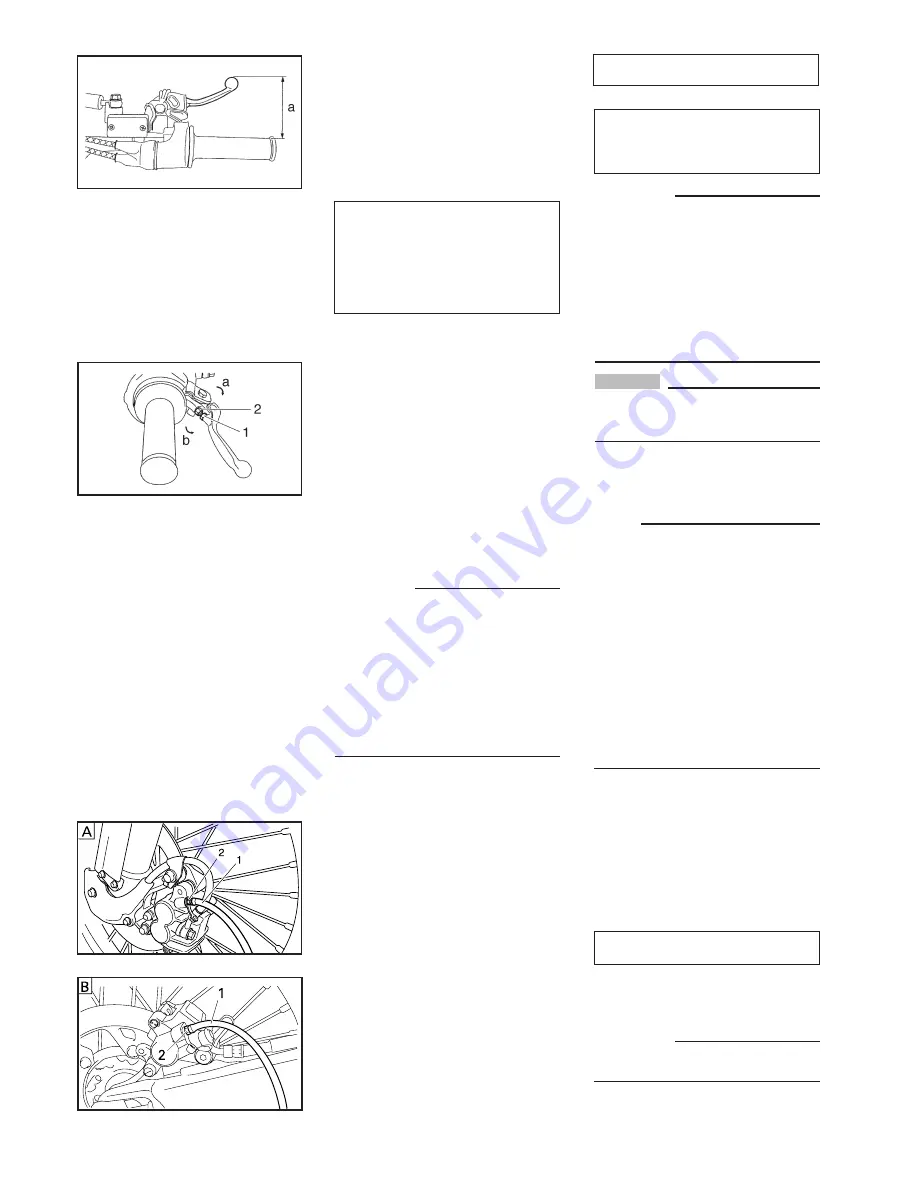

2. Adjust:

D

brake lever position

(distance (a) from the throttle grip to

the brake lever)

a. Loosen the locknut (1).

b. Turn the adjusting bolt (2) in direction

(a) or (b) until the specified brake lever

position is obtained.

c. Tighten the locknut.

Direction (a):

Brake lever distance is increased.

Direction (b):

Brake lever distance is decreased.

W

A soft or spongy feeling in the brake

lever can indicate the presence of air in

the brake system. Before the vehicle is

operated, the air must be removed by

bleeding the brake system. Air in the

brake system will considerably reduce

braking performance and could result

in loss of control and possibly an acci-

dent. Therefore, check the brake sys-

tem and bleed if necessary.

CAUTION:

After adjusting the brake lever posi-

tion, make sure that there is no brake

drag.

EAA01034

G. BLEEDING THE HYDRAULIC

BRAKE SYSTEM

W

Bleed the hydraulic brake system

whenever:

D

The system was disassembled,

D

A brake hose was loosened or

removed,

D

The brake fluid level is very low,

D

Brake operation is faulty.

A dangerous loss of braking perfor-

mance may occur if the brake system

is not properly bled.

1. Remove:

D

diaphragm

D

protector (rear brake)

NOTE:

D

Be careful not to spill any brake fluid or

allow the brake master cylinder reser-

voir to overflow.

D

When bleeding the hydraulic brake

system, make sure that there is always

enough brake fluid before applying the

brake. Ignoring this precaution could

allow air to enter the hydraulic brake

system, considerably lengthening the

bleeding procedure.

D

If bleeding is difficult, it may be neces-

sary to let the brake fluid settle for a

few hours. Repeat the bleeding proce-

dure when the tiny bubbles in the hose

have disappeared.

2. Bleed:

D

hydraulic brake system

a. Add the recommended brake fluid to

the proper level.

b. Install the brake master cylinder reser-

voir diaphragm.

c. Connect a clear plastic hose (1) tightly

to the bleed screw (2).

(A) Front brake

(B) Rear brake

d. Place the other end of the hose into a

container.

e. Slowly squeeze the brake lever several

times and release it.

f. Fully squeeze the brake lever and do

not release it.

g. Loosen the bleed screw. This will

release the tension and cause the

brake lever to contact the throttle grip.

h. Tighten the bleed screw and then

release the brake lever.

i. Repeat steps (e) to (h) until all of the

air bubbles have disappeared from the

brake fluid in the plastic hose.

j. Tighten the bleed screw to specifica-

tion.

Bleed screw:

6 Nm (0.6 m

d

kg, 4.3 ft

d

lb)

k. Fill the reservoir to the proper level.

Refer to "CHECKING THE BRAKE

FLUID LEVEL".

W

After bleeding the hydraulic brake sys-

tem, check the brake operation.

3. Install:

D

diaphragm

D

protector (rear brake)

-19-

Locknut:

5 Nm (0.5 m

d

kg, 3.6 ft

d

lb)