5-7

CARBURETOR

HANDLING NOTE

Do not loosen the screw (throttle

position sensor) "1" except when

changing the throttle position sen-

sor due to failure because it will

cause a drop in engine perfor-

mance.

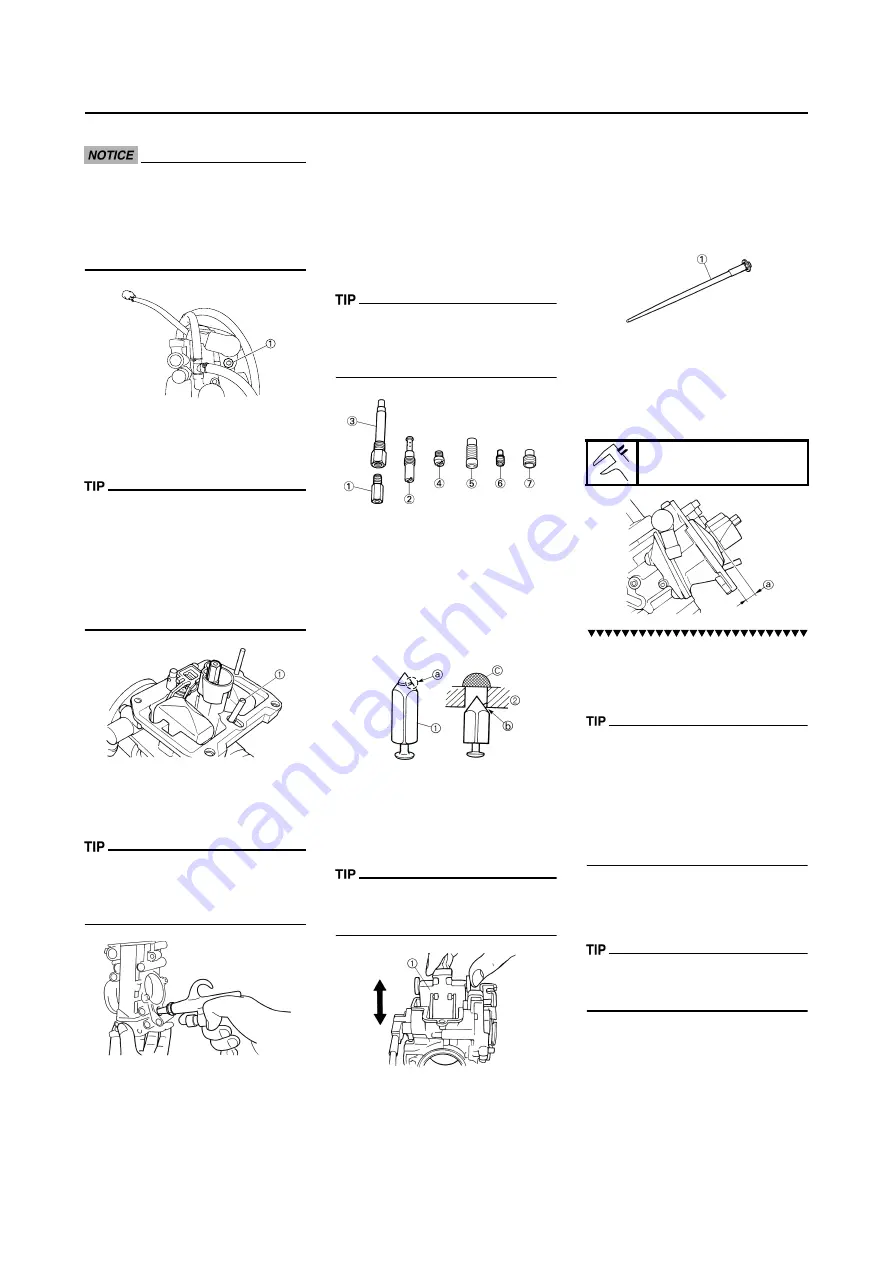

REMOVING THE PILOT SCREW

(For EUROPE)

1. Remove:

• Pilot screw "1"

To optimize the fuel flow at a small

throttle opening, each machine's pilot

screw has been individually set at the

factory. Before removing the pilot

screw, turn it in fully and count the

number of turns. Record this number

as the factory-set number of turns

out.

CHECKING THE CARBURETOR

1. Inspect:

• Carburetor body

Contamination

→

Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

2. Inspect:

• Main jet "1"

• Pilot jet "2"

• Needle jet "3"

• Starter jet "4"

• Pilot air jet "5"

• Leak jet "6"

• Main air jet "7"

Damage

→

Replace.

Contamination

→

Clean.

• Use a petroleum based solvent for

cleaning. Blow out all passages and

jets with compressed air.

• Never use a wire.

CHECKING THE NEEDLE VALVE

1. Inspect:

• Needle valve "1"

• Valve seat "2"

Grooved wear "a"

→

Replace.

Dust "b"

→

Clean.

• Filter "c"

Clogged

→

Clean.

CHECKING THE THROTTLE

VALVE

1. Check:

• Free movement

Stick

→

Repair or replace.

Insert the throttle valve "1" into the

carburetor body, and check for free

movement.

CHECKING THE JET NEEDLE

1. Inspect:

• Jet needle "1"

Bends/wear

→

Replace.

• Clip groove

Free play exists/wear

→

Replace.

MEASURING AND ADJUSTING

THE FLOAT HEIGHT

1. Measure:

• Float height "a"

Out of specification

→

Adjust.

Measurement and adjustment

steps:

a. Hold the carburetor in an upside

down position.

• Slowly tilt the carburetor in the op-

posite direction, then take the mea-

surement when the needle valve

aligns with the float arm.

• If the carburetor is level, the weight

of the float will push in the needle

valve, resulting in an incorrect mea-

surement.

b. Measure the distance between

the mating surface of the float

chamber and top of the float using

a vernier calipers.

The float arm should be resting on the

needle valve, but not compressing

the needle valve.

c. If the float height is not within

specification, inspect the valve

seat and needle valve.

d. If either is worn, replace them

both.

Float height:

8.0 mm (0.31 in)

Summary of Contents for WR250F(Y) 2009

Page 2: ......

Page 43: ......

Page 71: ...3 18 ENGINE INTAKE EXHAUST...

Page 84: ...3 31 ELECTRICAL Charging method using a variable voltage charger...

Page 85: ...3 32 ELECTRICAL Charging method using a constant voltage charger...

Page 223: ......