FUEL INJECTION SYSTEM

7-32

EAS27400

TROUBLESHOOTING METHOD

The engine operation is not normal and the

engine trouble warning light comes on.

1. Check:

●

Fault code number

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Check the fault code number displayed on

the meter.

b. Identify the faulty system with the fault code.

Refer to “Self-Diagnostic Funciton table”.

c. Identify the probable cause of the malfunc-

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

tion. Refer to “Fault code table”.

2. Check and repair the probable case of mal-

function.

3. Perform the fuel injection system reinstate-

ment action.

Refer to “Reinstatement method” of table in

“TROUBLESHOOTING DETAILS” on page

7-41.

4. Turn the main switch to “OFF” and back to

“ON”, then check that no fault code number is

displayed.

NOTE:

If fault codes are displayed, repeat steps (1) to

(4) until no fault code number is displayed.

5. Erase the malfuction history in the diagnostic

mode. Refer to “Sensor operation table (Di-

agnostic code No.62)”.

NOTE:

Turning the main switch to “OFF” will not erase

the malfuction history.

The engine operation is not normal but the

engine trouble warning light does not come

on.

1. Check the operation of following sensors and

actuators in the Diagnostic mode. “ Refer to

“Sensor operation table” and “Actuator oper-

ation table”.

If a malfunction is detected in the sensors or

actuators, repair or replace all faulty parts.

If no malfunction is detected in the sensors

and actuators, check and repair inner parts of

the engine.

EAS27440

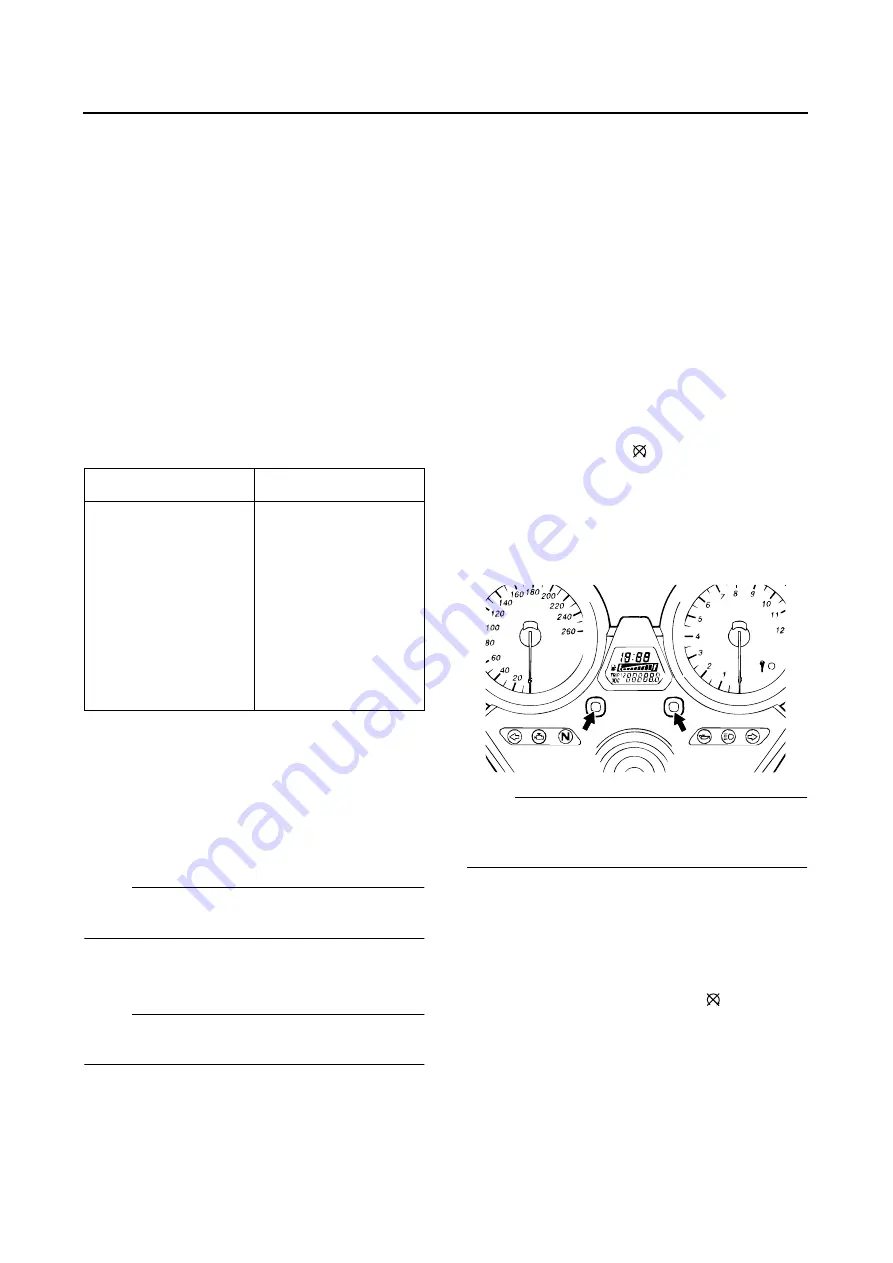

DIAGNOSTIC MONITORING MODE

Setting the diagnostic monitoring mode

1. Turn the main switch to “OFF” and set the en-

gine stop switch to “

”.

2. Disconnect the wire harness coupler from the

fuel pump.

3. Press the SELECT button and RESET button

simultaneously, turn the main switch “ON”,

and keep switch pressed for at least 8 sec-

onds.

NOTE:

●

All displays on the meter disappear except the

clock and tripmeter displays.

●

“dIAG” appears on the clock LCD.

4. Press the SELECT button to select the CO

adjustment mode “CO” or the diagnostic

monitoring mode “dIAG”.

5. After selecting “CO”, press the SELECT and

RESET buttons simultaneously for at least 2

seconds.

6. Set the engine stop switch to “

”.

7. Select the diagnostic monitoring code num-

ber that applies to the item that was verified

with the fault code number by pressing the

SELECT and RESET buttons.

Fault code No.

No fault code No.

Check and repair.

Refer to

SHOOTING DETAILS”

on page 7-41.

Monitor the opera-

tion of the sensors

and actuators in the

diagnostic mode.

Refer to “Sensor

operation table” and

“Actuator operation

table”.

Check and repair.

Summary of Contents for XJR1300 2007

Page 1: ...SERVICE MANUAL XJR1300 W 5WM 28197 E0 2007 ...

Page 2: ......

Page 8: ......

Page 47: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 24 ...

Page 48: ...LUBRICATION DIAGRAMS 2 25 EAS28860 LUBRICATION DIAGRAMS ...

Page 50: ...LUBRICATION DIAGRAMS 2 27 ...

Page 51: ...LUBRICATION DIAGRAMS 2 28 1 Drive axle 2 Push rod 3 Main axle 4 Camshaft 5 Crankshaft ...

Page 52: ...LUBRICATION DIAGRAMS 2 29 ...

Page 53: ...LUBRICATION DIAGRAMS 2 30 1 Nozzle 2 Bypass valve 3 Oil filter element 4 Relief valve ...

Page 54: ...CABLE ROUTING 2 31 EAS20430 CABLE ROUTING ...

Page 56: ...CABLE ROUTING 2 33 ...

Page 58: ...CABLE ROUTING 2 35 ...

Page 60: ...CABLE ROUTING 2 37 ...

Page 62: ...CABLE ROUTING 2 39 ...

Page 64: ...CABLE ROUTING 2 41 ...

Page 66: ...CABLE ROUTING 2 43 ...

Page 68: ...CABLE ROUTING 2 45 ...

Page 70: ...CABLE ROUTING 2 47 ...

Page 205: ...GENERATOR 5 32 b Measure the stator coil resistances 1 2 ...

Page 240: ...STARTER CLUTCH 5 67 1 3 2 New ...

Page 260: ...FUEL TANK 6 3 fuel hose end in the direction of the arrow 1 ...

Page 269: ...THROTTLE BODIES 6 12 ...

Page 270: ...AIR INDUCTION SYSTEM 6 13 EAS27040 AIR INDUCTION SYSTEM 1 2 3 4 4 5 4 4 3 2 1 1 2 4 3 ...

Page 274: ...AIR INDUCTION SYSTEM 6 17 ...

Page 277: ......

Page 278: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 282: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 288: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 289: ...CHARGING SYSTEM 7 12 1 Generator 2 Main switch 4 Main fuse 7 Battery ...

Page 291: ...CHARGING SYSTEM 7 14 ...

Page 292: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 295: ...LIGHTING SYSTEM 7 18 ...

Page 296: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 302: ...FUEL INJECTION SYSTEM 7 25 EAS27330 FUEL INJECTION SYSTEM EAS27340 CIRCUIT DIAGRAM ...

Page 342: ...FUEL PUMP SYSTEM 7 65 EAS27580 FUEL PUMP SYSTEM EAS27590 CIRCUIT DIAGRAM ...

Page 345: ...FUEL PUMP SYSTEM 7 68 ...

Page 346: ...IMMOBILIZER SYSTEM 7 69 EAS27640 IMMOBILIZER SYSTEM EAS27650 CIRCUIT DIAGRAM ...

Page 355: ...IMMOBILIZER SYSTEM 7 78 ...

Page 361: ...ELECTRICAL COMPONENTS 7 84 a b Br R Br R ...

Page 382: ......

Page 383: ......

Page 384: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...