ENGINE

3-4

EAS20470

ENGINE

EAS20490

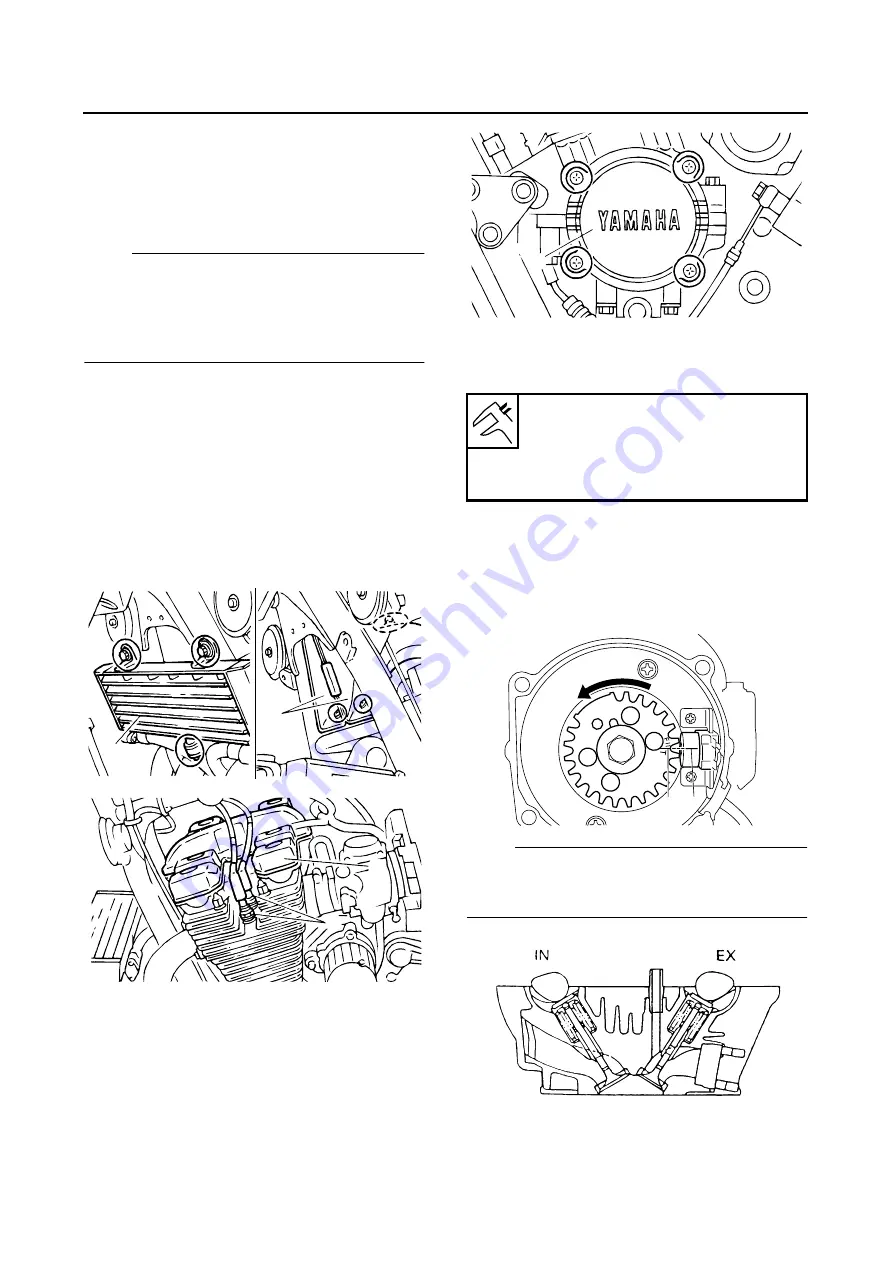

ADJUSTING THE VALVE CLEARANCE

The following procedure applies to all of the

valves.

NOTE:

●

Valve clearance adjustment should be made

on a cold engine, at room temperature.

●

When the valve clearance is to be measured or

adjusted, the piston must be at top dead center

(TDC) on the compression stroke.

1. Remove:

●

Oil cooler “1”

●

Air scoop “2”

Refer to “ENGINE REMOVAL” on page 5-1.

●

Air induction system

Refer to “AIR INDUCTION SYSTEM” on

page 6-13.

●

Spark plug “3”

●

Cylinder head cover “4”

●

Timing plate cover “5”

Refer to “CAMSHAFTS” on page 5-5.

2. Measure:

●

Valve clearance

Out of specification

→

Adjust.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft clockwise.

b. When the piston is at TDC on the compres-

sion stroke, align the mark “a” on the pickup

coil rotor with the mark “b” on the crankcase

cover. (TDC)

NOTE:

TDC on the compression stroke can be found

when the camshaft lobes are turned away from

each other.

c. Measure the valve clearance with a thickness

gauge “1”.

1

2

4

3

Valve clearance (cold)

Intake

0.11

–

0.15 mm (0.0043

–

0.0059 in)

Exhaust

0.16

–

0.20 mm (0.0063

–

0.0079 in)

5

a b

Summary of Contents for XJR1300 2007

Page 1: ...SERVICE MANUAL XJR1300 W 5WM 28197 E0 2007 ...

Page 2: ......

Page 8: ......

Page 47: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 24 ...

Page 48: ...LUBRICATION DIAGRAMS 2 25 EAS28860 LUBRICATION DIAGRAMS ...

Page 50: ...LUBRICATION DIAGRAMS 2 27 ...

Page 51: ...LUBRICATION DIAGRAMS 2 28 1 Drive axle 2 Push rod 3 Main axle 4 Camshaft 5 Crankshaft ...

Page 52: ...LUBRICATION DIAGRAMS 2 29 ...

Page 53: ...LUBRICATION DIAGRAMS 2 30 1 Nozzle 2 Bypass valve 3 Oil filter element 4 Relief valve ...

Page 54: ...CABLE ROUTING 2 31 EAS20430 CABLE ROUTING ...

Page 56: ...CABLE ROUTING 2 33 ...

Page 58: ...CABLE ROUTING 2 35 ...

Page 60: ...CABLE ROUTING 2 37 ...

Page 62: ...CABLE ROUTING 2 39 ...

Page 64: ...CABLE ROUTING 2 41 ...

Page 66: ...CABLE ROUTING 2 43 ...

Page 68: ...CABLE ROUTING 2 45 ...

Page 70: ...CABLE ROUTING 2 47 ...

Page 205: ...GENERATOR 5 32 b Measure the stator coil resistances 1 2 ...

Page 240: ...STARTER CLUTCH 5 67 1 3 2 New ...

Page 260: ...FUEL TANK 6 3 fuel hose end in the direction of the arrow 1 ...

Page 269: ...THROTTLE BODIES 6 12 ...

Page 270: ...AIR INDUCTION SYSTEM 6 13 EAS27040 AIR INDUCTION SYSTEM 1 2 3 4 4 5 4 4 3 2 1 1 2 4 3 ...

Page 274: ...AIR INDUCTION SYSTEM 6 17 ...

Page 277: ......

Page 278: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 282: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 288: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 289: ...CHARGING SYSTEM 7 12 1 Generator 2 Main switch 4 Main fuse 7 Battery ...

Page 291: ...CHARGING SYSTEM 7 14 ...

Page 292: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 295: ...LIGHTING SYSTEM 7 18 ...

Page 296: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 302: ...FUEL INJECTION SYSTEM 7 25 EAS27330 FUEL INJECTION SYSTEM EAS27340 CIRCUIT DIAGRAM ...

Page 342: ...FUEL PUMP SYSTEM 7 65 EAS27580 FUEL PUMP SYSTEM EAS27590 CIRCUIT DIAGRAM ...

Page 345: ...FUEL PUMP SYSTEM 7 68 ...

Page 346: ...IMMOBILIZER SYSTEM 7 69 EAS27640 IMMOBILIZER SYSTEM EAS27650 CIRCUIT DIAGRAM ...

Page 355: ...IMMOBILIZER SYSTEM 7 78 ...

Page 361: ...ELECTRICAL COMPONENTS 7 84 a b Br R Br R ...

Page 382: ......

Page 383: ......

Page 384: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...