7 - 1

FI

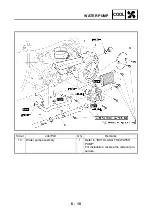

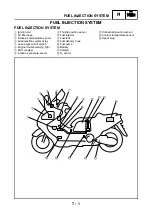

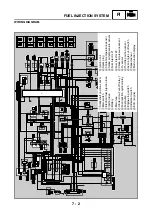

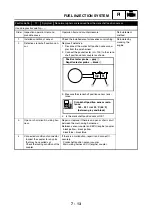

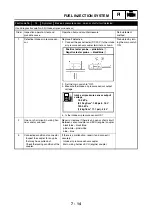

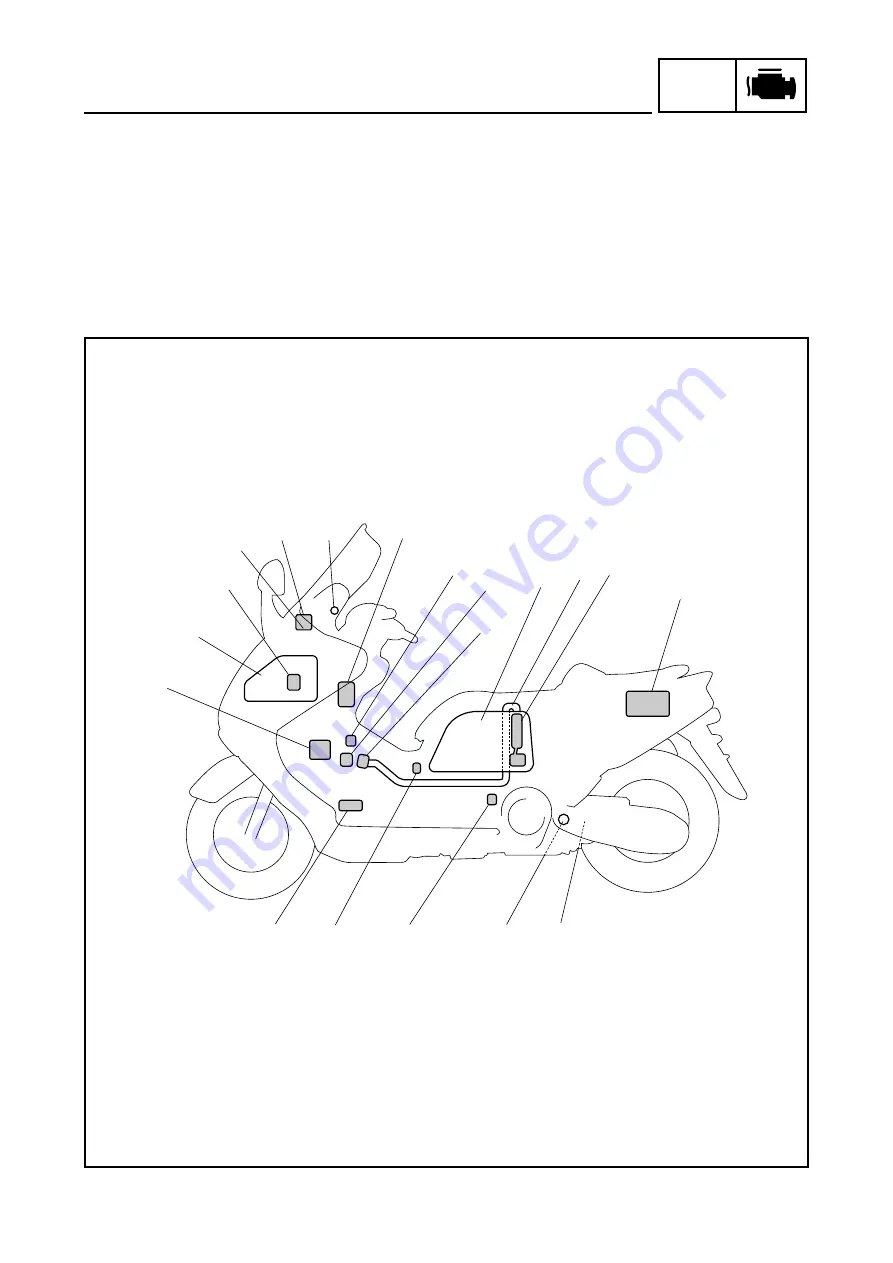

FUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM

1

Ignition coil

2

Air filter case

3

Intake air temperature sensor

4

Fuel injection system relay

5

Lean angle cut-off switch

6

Engine trouble warning light

7

ECU (engine)

8

Intake air pressure sensor

9

Throttle position sensor

0

Fuel injector

A

Fuel tank

B

Fuel delivery hose

C

Fuel pump

D

Battery

E

Catalyst

F

O

2

sensor

G

Crankshaft position sensor

H

Coolant temperature sensor

I

Spark plug

1

2

3

4

5

6

7

8

9

0

A

B C

D

F

E

G

H

I

Summary of Contents for XP500

Page 1: ...2005 XP500 XP500A5VU5 AE1 SERVICE MANUAL...

Page 2: ......

Page 8: ......

Page 9: ...GEN INFO 1...

Page 11: ...GEN INFO...

Page 38: ...SPEC 2...

Page 40: ...SPEC...

Page 68: ...2 28 SPEC OIL FLOW DIAGRAMS 1 Oil strainer 2 Crankshaft...

Page 69: ...2 29 SPEC OIL FLOW DIAGRAMS 1 Clutch 2 Right main journal bearing 3 Main gallery plug...

Page 118: ......

Page 119: ...CHK ADJ 3...

Page 193: ......

Page 194: ...CHAS 4...

Page 198: ...CHAS...

Page 292: ...4 94 CHAS ANTI LOCK BRAKE SYSTEM XP500A...

Page 326: ......

Page 327: ...ENG 5...

Page 331: ...ENG...

Page 424: ...COOL 6...

Page 426: ...COOL...

Page 442: ......

Page 443: ...FI 7...

Page 445: ...FI...

Page 476: ...ELEC 8...

Page 544: ......

Page 545: ...TRBL SHTG 9...

Page 553: ......

Page 556: ......

Page 557: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN...