7*20 Brakes, wheels and tyres

NORTH AMERICAN

DEPARTMENT OF TRANSPORT

COMPLIANCE SYMBOL

ARROW DENOTING

THE DIRECTION OF

WHEEL ROTATION

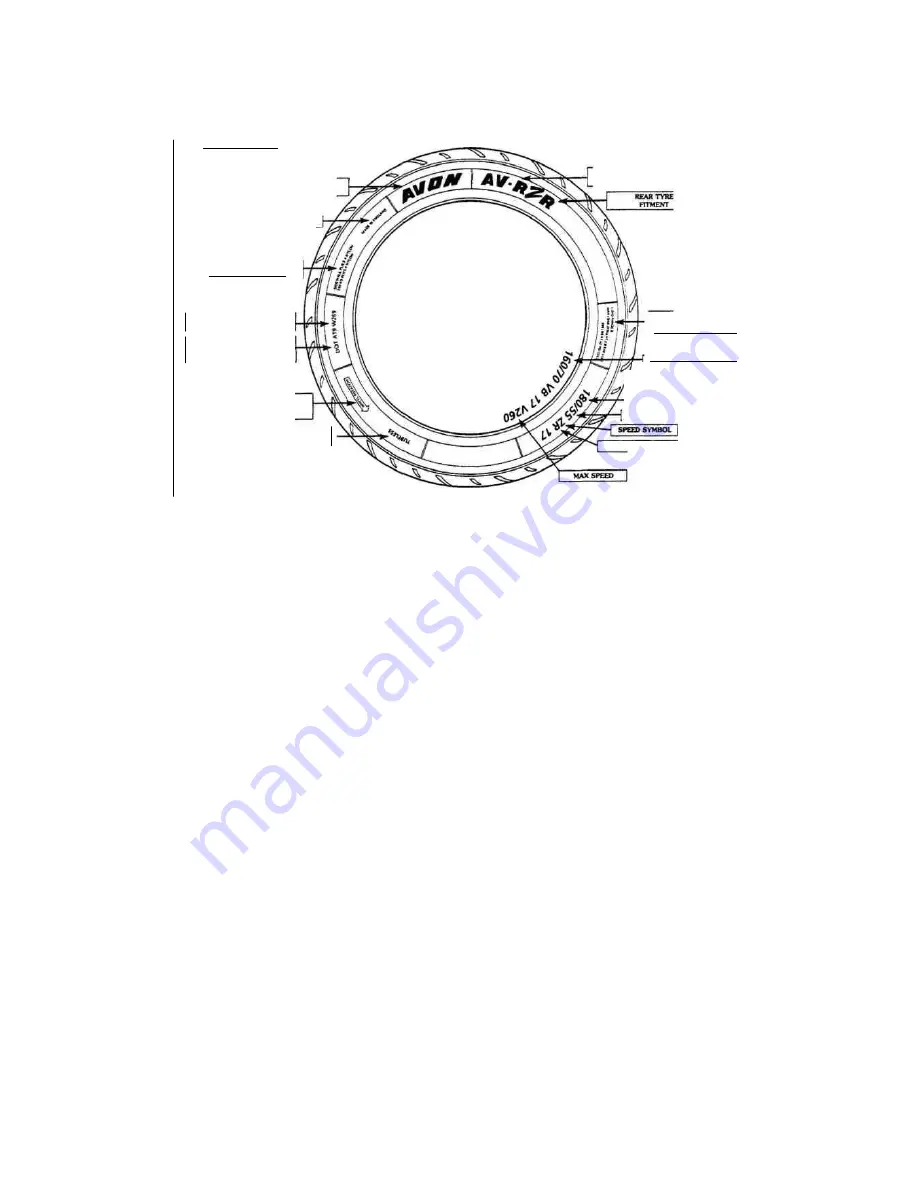

14.3 Common tyre sidewall markings

the

beginning

of

this

manual

for

tyre

maintenance.

Fitting new tyres

3 When selecting new tyres, refer to the tyre

information label on the swingarm and the tyre

options listed in the owners handbook. Ensure

that front and rear tyre types are compatible, the

correct size and correct speed rating; if

necessary seek advice from a Yamaha dealer or

tyre fitting specialist

(see illustration).

4

it is recommended that tyres are fitted by a

motorcycle tyre specialist rather than attempted

in the home workshop. This is particularly

relevant in the case of tubeless tyres because

the force required to break the seal between the

wheel rim and tyre bead is substantial, and is

usually beyond the capabilities of an individual

working with normal tyre levers. Additionally, the

specialist will be able to balance the wheels after

tyre fitting. 5 Note that punctured tubeless tyres

can in

some cases be repaired. Any such repairs must

be carried out professionally by a motorcycle tyre

fitting specialist and advice sought on reduced

speed limits for repaired tyres.

6 A punctured tubed tyre is best repaired by

fitting a new inner tube and of course removing

the item which caused the puncture from the tyre

tread. Inner tubes can be repaired using a kit, but

the safest option is to renew the inner tube.

Scaned by Stalker

A COMMERCIAL NAME

OR IDENTITY

MANUFACTURERS NAME

OR BRAND NAME

COUNTRY OF MANUFACTURE

TYRE CONSTRUCTION DETAILS

fNQT REQUIRED IN UK)

LOAD AND PRESSURE

MARKING REQUIREMENT

(NOT APPLICABLE IN UK)

NORTH AMERICAN TYRE

IDENTIFICATION NUMBER

BIAS BELTED TYRE SIZE ]

TYRE SIZE DESIGNATION

TYRE% PROFILE |

RADIAL CONSTRUCTION

THE WORD TUBELESS

WHIM! APPLICABLE