4-22

VALVES AND VALVE SPRINGS

ENG

*****************************************************

*****************************************************

NOTE:

a

b

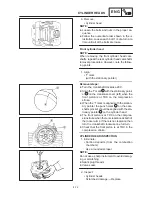

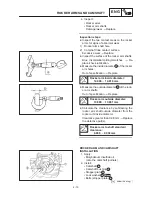

VALVE AND VALVE SPRING REMOVAL

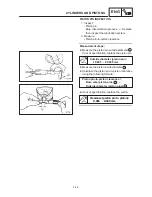

1. Check:

S

Valve sealing

Leakage at the valve seat

Inspect the

valve face, valve seat and valve seat

width.

Refer to “INSPECTION”.

Checking steps:

D

Pour a clean solvent

1

into the intake and

exhaust ports.

D

Check that the valve seals properly.

There should be no leakage at the valve seat

2

.

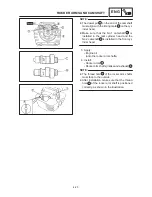

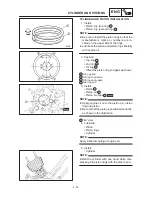

2. Remove:

S

Valve cotters

Attach a valve spring compressor

1

between

the valve spring retainer and the cylinder head

to remove the valve cotters.

Valve spring compressor:

90890-04019

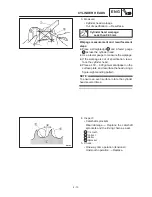

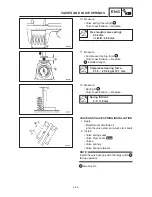

VALVE AND VALVE SPRING INSPECTION

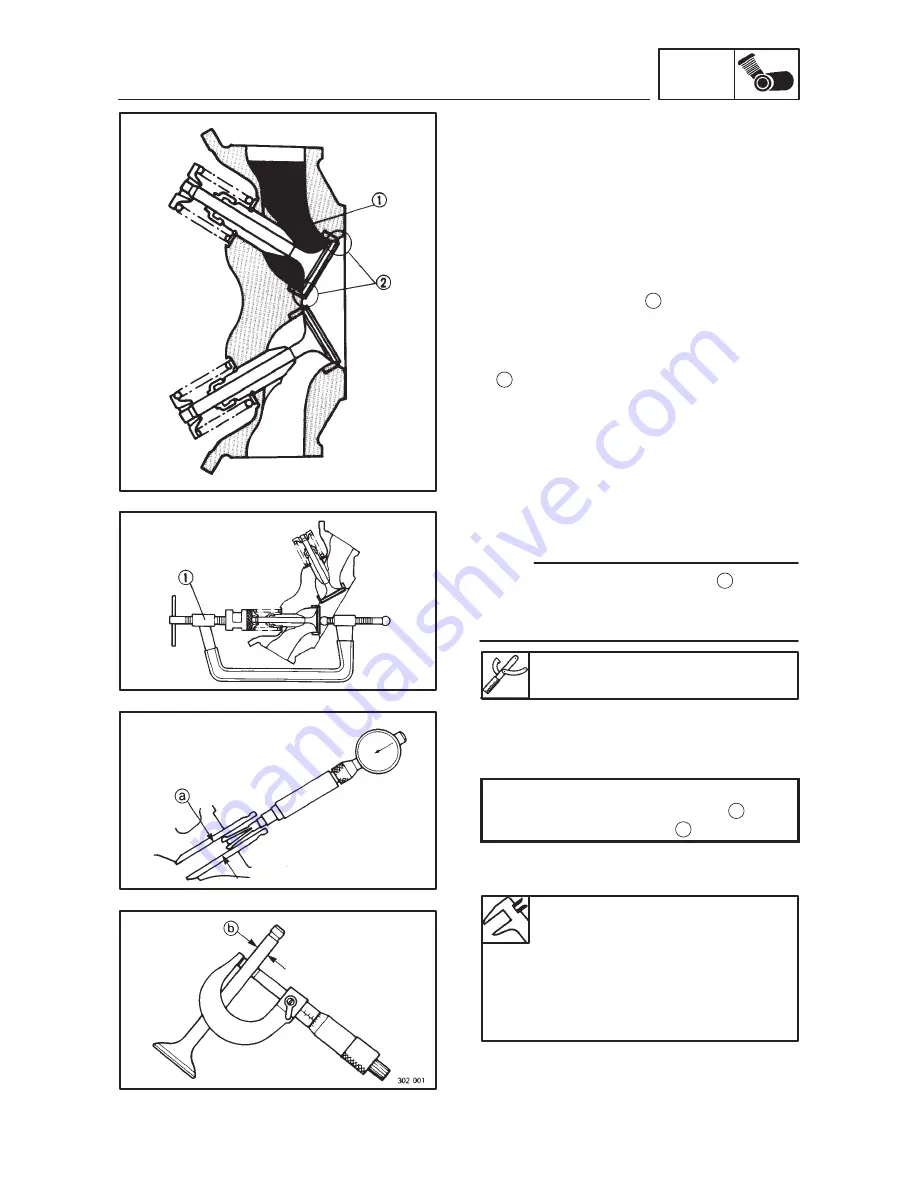

1. Measure:

S

Stem-to-guide clearance

Stem-to-guide clearance =

valve guide inside diameter –

valve stem diameter

Out of specification

Replace the valve

guide.

Clearance (stem to guide):

Intake:

0.010

0.037 mm

<Limit>:

0.08 mm

Exhaust:

0.025

0.052 mm

<Limit>:

0.10 mm

Summary of Contents for XVS6501997

Page 1: ......

Page 2: ......

Page 8: ......

Page 10: ...GEN INFO ...

Page 18: ...GEN INFO ...

Page 20: ...SPEC ...

Page 44: ...2 24 LUBRICATION DIAGRAMS SPEC 1 Crankshaft 2 Oil filter 3 Oil pump ...

Page 102: ...INSP ADJ ...

Page 188: ...CARB ...

Page 198: ...CARB ...

Page 266: ...CHAS ...

Page 268: ...ELEC SELF DIAGNOSIS 7 49 TROUBLESHOOTING 7 50 ...

Page 298: ...E 7 30 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 320: ...TRBL SHTG ...

Page 326: ...TRBL SHTG ...