ENG

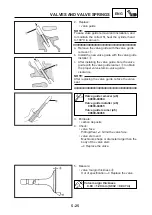

VALVES AND VALVE SPRINGS

CHECKING THE VALVE SPRINGS

The following procedure applies to all of the valve

springs.

1. Measure:

• spring free length

a

Out of specification

-->

Replace.

2. Measure:

• compressed spring force

a

Out of specification

-->

Replace.

b

Installed length

3. Measure:

• spring tilt

a

Out of specification

-->

Replace.

Spring tilt limit (all)

2.5

o

/1.6 mm (2.5°/0.063 in)

a

Spring free length

Intake (inside)

36.17mm (1.424 in)

<limit>: 34.47mm (1.357 in)

Exhaust (inside)

36.17mm (1.424 in)

<limit>: 34.47mm (1.357 in)

Intake (outside)

36.63mm (1.442 in)

<limit>: 34.63mm (1.363 in)

Exhaust (outside)

36.63mm (1.442 in)

<limit>: 34.63mm (1.363 in)

a

b

Compressed spring force

Inside

75 ~ 91 N at 30.5 mm

(7.50 ~ 9.10 kgf at 30.5 mm,

17 ~ 20.5 lbf at 1.20 in)

Outside

128.5 ~ 157.9 N at 32.0 mm

(12.85 ~ 15.79 kgf.m at 32.0 mm

29 ~ 36 lbf at 1.26 in)

a

5-28

Summary of Contents for YBR250 2007

Page 1: ...YBR250 SERVICE MANUAL 5D1 F8197 E0 2007 ...

Page 2: ......

Page 359: ...YAMAHA MOTOR DA AMAZÔNIA LTDA ...