4 - 56

ENG

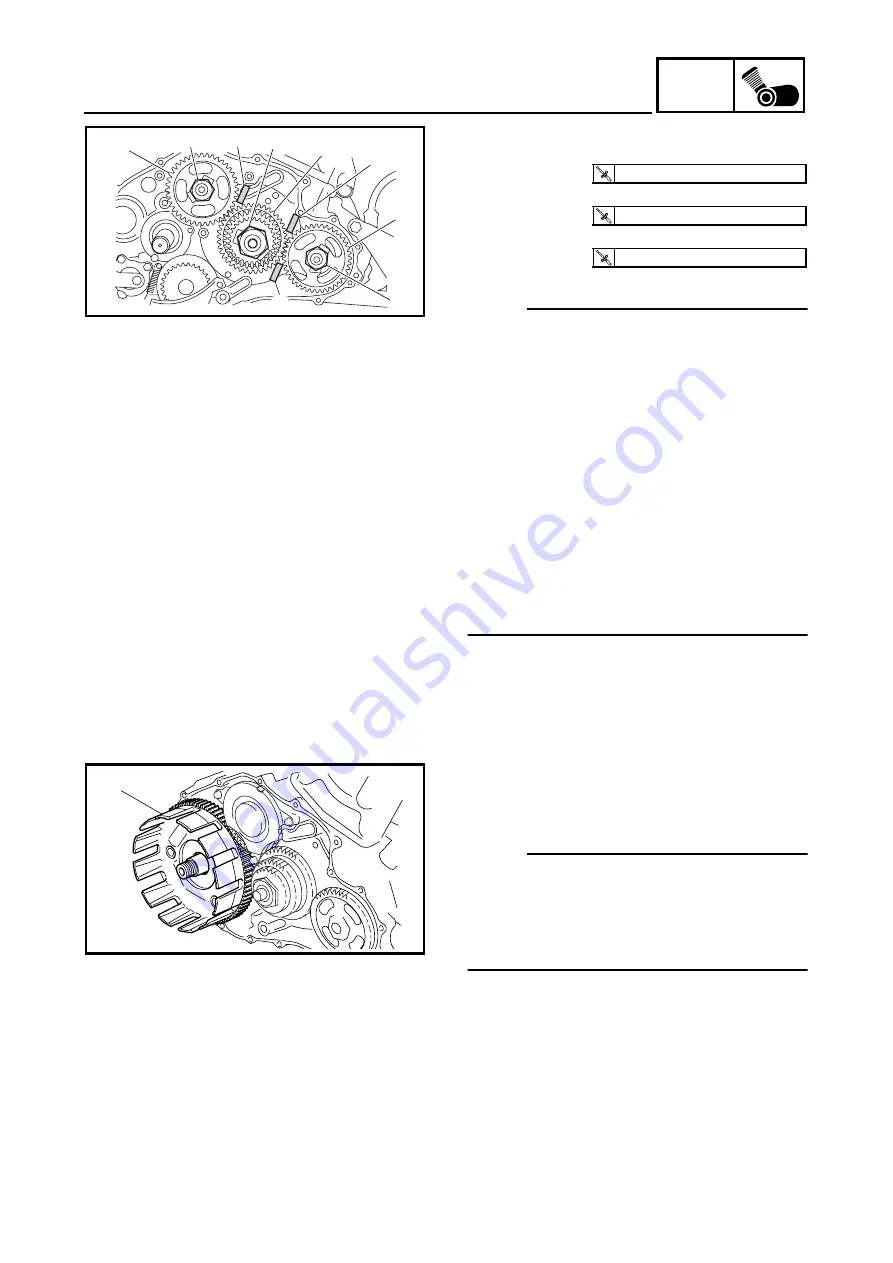

2. Tighten:

• balancer driven gear 2 nut

1

• primary drive gear nut

2

• balancer driven gear 1 nut

3

NOTE:

_

• Apply the engine oil to the balancer threads.

• Apply the molybdenum disulfide grease to

the crankshaft and nut

2

threads.

• Place an aluminum plate

4

between the

teeth of the balancer driven gear 2

5

and

balancer drive gear

6

, then tighten the nut

1

.

• Place an aluminum plate

7

between the

teeth of the balancer driven gear 2

5

and

balancer drive gear

6

, then tighten the nut

2

.

• Place an aluminum plate

8

between the

teeth of the balancer drive gear

6

and bal-

ancer driven gear 1

9

, then tighten the nut

3

.

3. Bend the lock washer tabs along a flat side

of the nut.

5

6

2

9

3

7

8

4

1

T

R

.

.

60 Nm (6.0 m · kg, 43 ft · lb)

T

R

.

.

110 Nm (11.0 m · kg, 80 ft · lb)

T

R

.

.

60 Nm (6.0 m · kg, 43 ft · lb)

EBS00311

INSTALLING THE CLUTCH

1. Install:

• clutch housing

1

NOTE:

_

• Make sure that the primary driven gear teeth

and primary drive gear teeth mesh correctly.

• Make sure that the oil pump drive gear teeth

and oil pump driven gear teeth mesh cor-

rectly.

1

Summary of Contents for YFM700RV 2009

Page 1: ...YFM700RV SERVICE MANUAL 1S3 28197 E0 ...

Page 34: ...2 11 SPEC ENGINE SPECIFICATIONS Cylinder head tightening sequence 1 3 2 4 5 7 8 6 ...

Page 52: ...2 29 SPEC OIL FLOW DIAGRAMS 1 Oil delivery pipe 2 Oil filter 3 Oil pump 2 3 A A A A 2 1 ...

Page 55: ...2 32 SPEC OIL FLOW DIAGRAMS 1 Balancer 1 2 Crankshaft 2 1 ...

Page 408: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...