3-44

CHK

ADJ

EAS00168

CHECKING THE WHEELS

The following procedure applies to both of the

wheels.

1. Check:

8

wheel

Damage/out-of-round

J

Replace.

w

Never attempt to make any repairs to the

wheel.

NOTE:

After a tire or wheel has been changed or re-

placed, always balance the wheel.

EAS00170

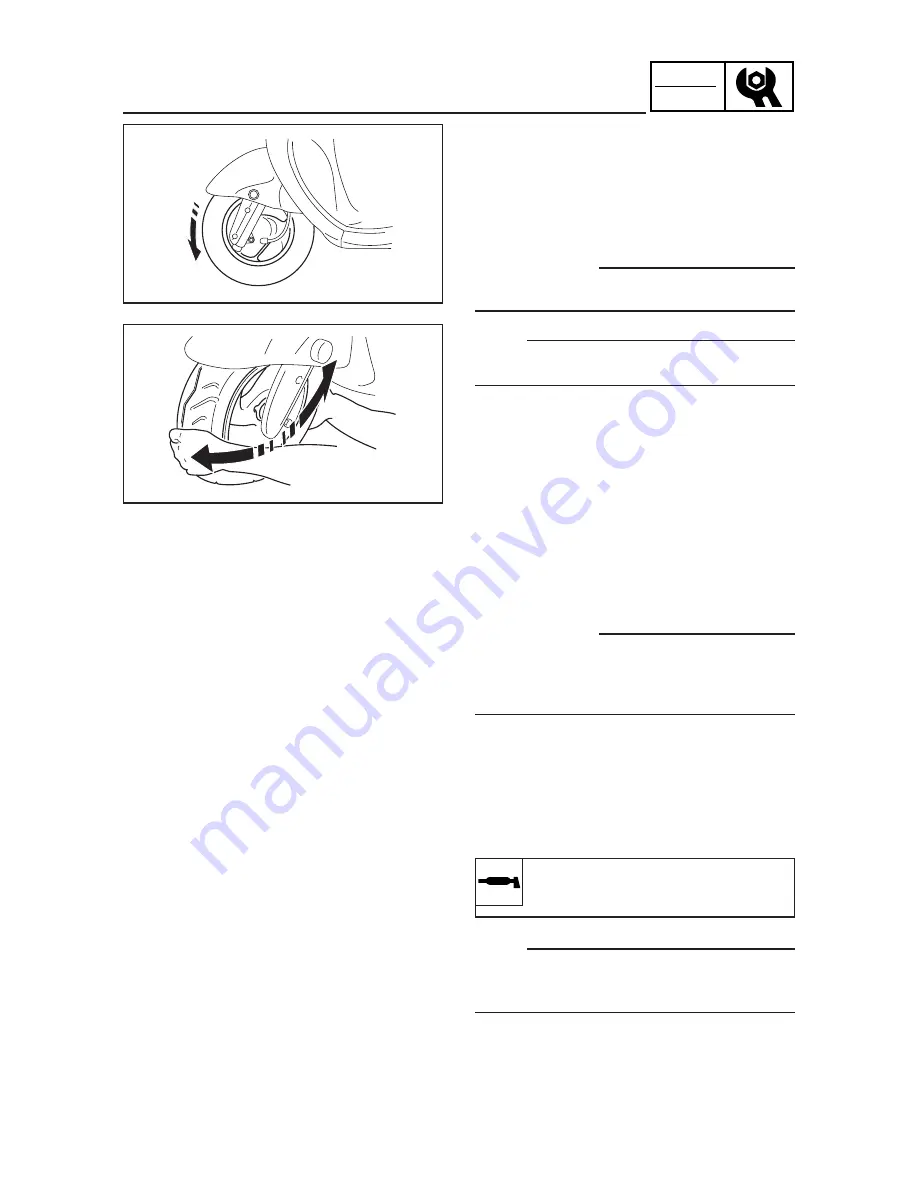

CHECKING AND LUBRICATING THE

CABLES

The following procedure applies to all of the in-

ner and outer cables.

w

Damaged outer cable may cause the cable

to corrode and interfere with its movement.

Replace damaged outer cable and inner

cables as soon as possible.

1. Check:

8

outer cable

Damage

J

Replace.

2. Check:

8

cable operation

Rough movement

J

Lubricate.

Recommended lubricant

Engine oil or a suitable cable

lubricant

NOTE:

Hold the cable end upright and pour a few drops

of lubricant into the cable sheath or use a suit-

able lubricating device.

CHECKING THE WHEELS/

CHECKING AND LUBRICATING THE CABLES