8-11

8

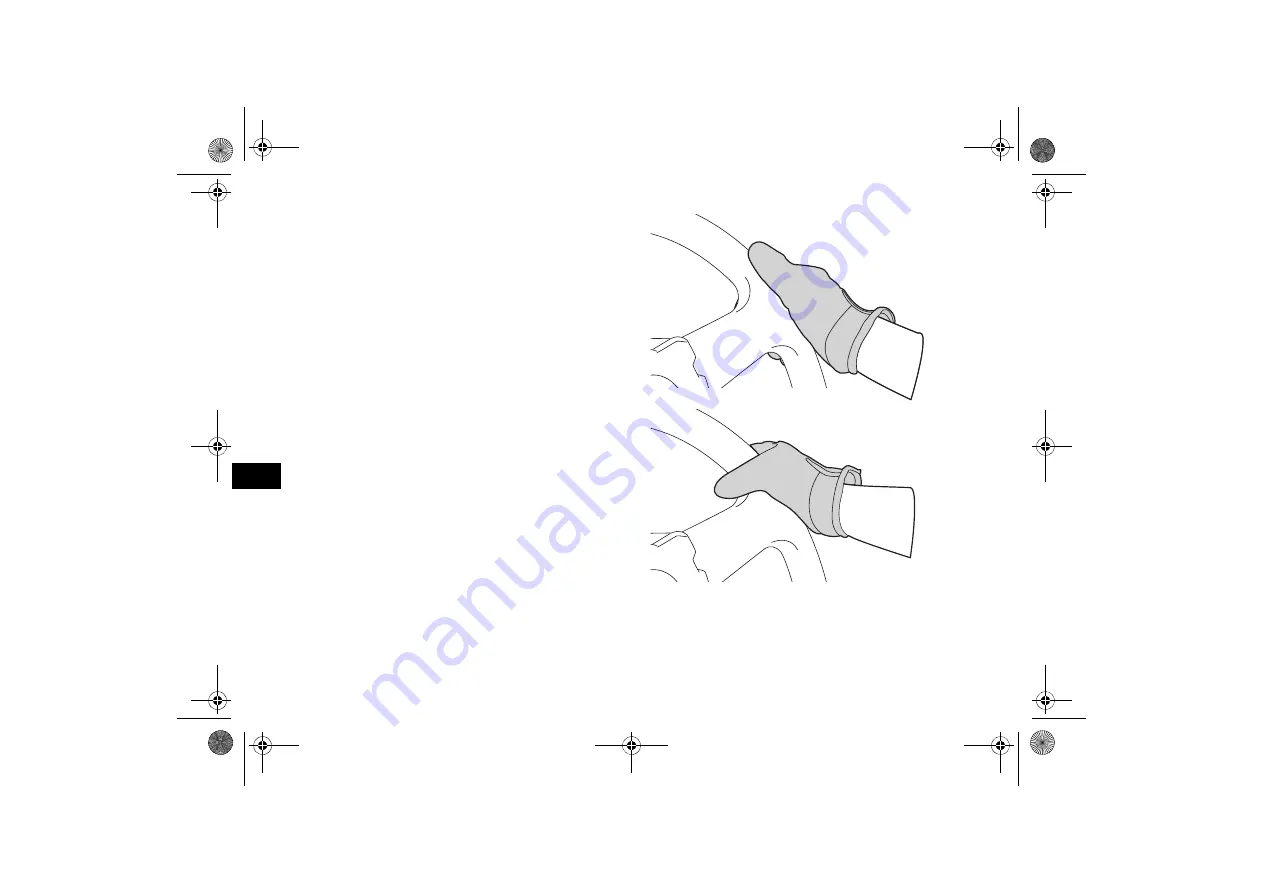

briefly jerk in one direction or back and forth

as the tires and vehicle respond to the obsta-

cle. This quick motion could injure your

thumbs or wrist if your thumbs or hand(s) are

inside the steering wheel. Grip the steering

wheel so that your thumbs will not be hit by

the spokes. As an example, see the illustra-

tion.

CORRECT GRIP EXAMPLE

I

N

CORRECT GRIP EXAMPLE

UBAS7AE0.book Page 11 Wednesday, June 19, 2019 11:51 AM