FRONT BRAKE

4-19

NOTICE

Brake fluid may damage painted surfaces

and plastic parts. Therefore, always clean

up any spilt brake fluid immediately.

5. Bleed:

• Brake system

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

6. Check:

• Brake fluid level

The minimum level mark or below

Add.

Refer to “CHECKING THE BRAKE FLUID

LEVEL” on page 3-26.

7. Check:

• Brake lever free play

Refer to “ADJUSTING THE FRONT

BRAKE” on page 3-22.

• Brake lever operation

A softy or spongy feeling

Bleed the brake

system.

Refer to “BLEEDING THE BRAKE SYS-

TEM” on page 3-21.

EASB291152

REMOVING THE FRONT BRAKE MASTER

CYLINDER

TIP

Before removing the front brake master cylin-

der, drain the brake fluid from the entire brake

system.

1. Remove:

• Union bolt

• Copper washers

• Brake hoses

TIP

To drain any remaining brake fluid, place a con-

tainer under the master cylinder and the end of

the brake hose.

EASB291153

CHECKING THE FRONT BRAKE MASTER

CYLINDER

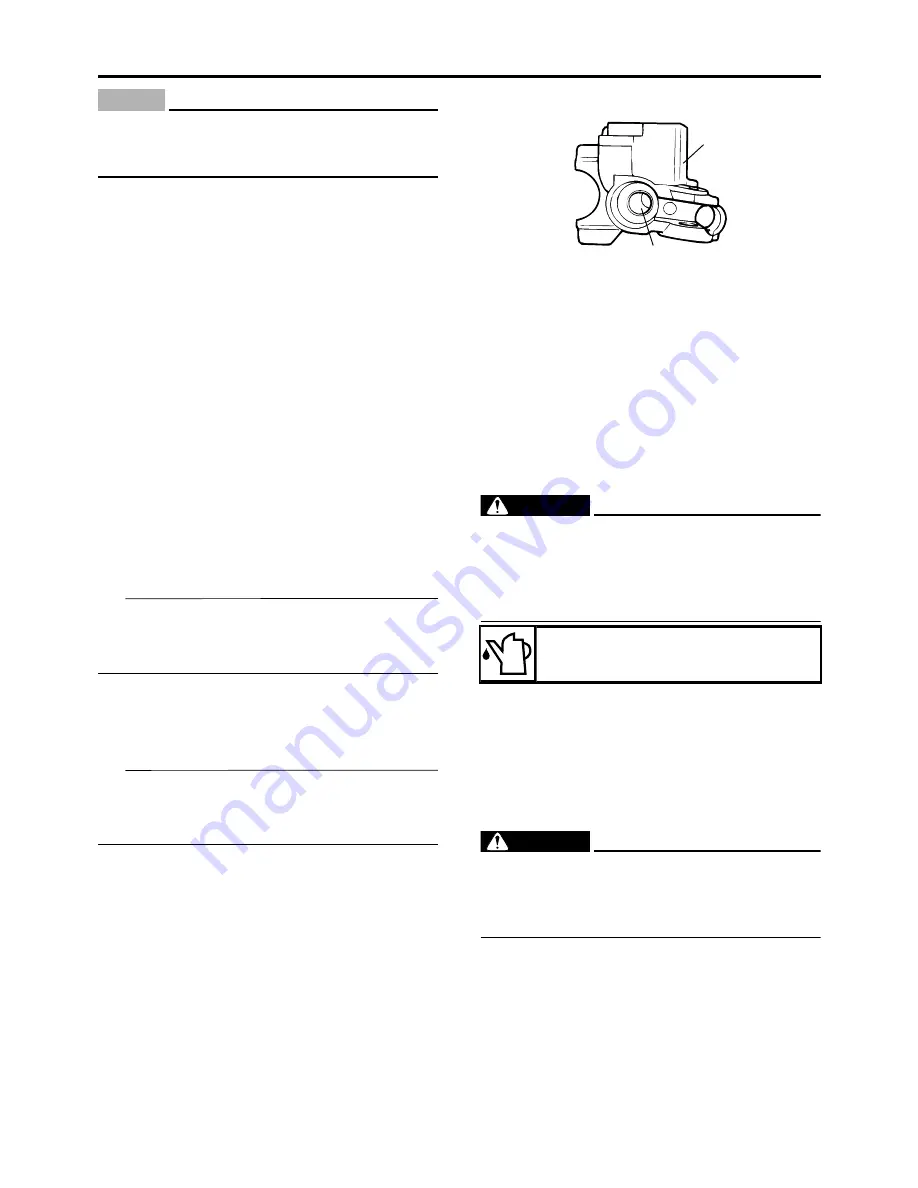

1. Check:

• Brake master cylinder “1”

Damage/scratches/wear

Replace.

• Brake fluid delivery passages “2”

(brake master cylinder body)

Obstruction

Blow out with compressed

air.

2. Check:

• Brake master cylinder kit

Damage/scratches/wear

Replace.

3. Check:

• Brake master cylinder reservoir cap

4. Check:

• Brake hoses

Cracks/damage/wear

Replace.

EASB291154

ASSEMBLING THE FRONT BRAKE MAS-

TER CYLINDER

EWA

WARNING

• Before installation, all internal brake com-

ponents should be cleaned and lubricated

with clean or new brake fluid.

• Never use solvents on internal brake com-

ponents.

1. Wash the brake master cylinder and the

brake master cylinder kit with brake fluid.

2. Install:

• Primary cylinder cup “1”

• Secondary cylinder cup “2”

Install to the brake master cylinder piston

“3”.

EWA

WARNING

Apply brake fluid to the cylinder cups and

install them as shown. Wrong orientation in

installation causes poor braking perfor-

mance.

Recommended brake fluid

DOT 4

1

2

Summary of Contents for YZ 2015 Series

Page 6: ...EASB291006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 33: ...CONTROL FUNCTIONS 1 21 a 2...

Page 65: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22 EASB291066...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 72: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 74: ...CABLE ROUTING DIAGRAM 2 31 EASB291068 CABLE ROUTING DIAGRAM...

Page 76: ...CABLE ROUTING DIAGRAM 2 33...

Page 78: ...CABLE ROUTING DIAGRAM 2 35...

Page 80: ...CABLE ROUTING DIAGRAM 2 37...

Page 82: ...CABLE ROUTING DIAGRAM 2 39...

Page 84: ...CABLE ROUTING DIAGRAM 2 41...

Page 86: ...CABLE ROUTING DIAGRAM 2 43...

Page 88: ...CABLE ROUTING DIAGRAM 2 45...

Page 128: ...ELECTRICAL SYSTEM 3 38...

Page 200: ...CHAIN DRIVE 4 70...

Page 244: ...ELECTRIC STARTER 5 41...

Page 266: ...OIL PUMP AND BALANCER GEAR 5 63 c d 6 6 7 8 8 b...

Page 286: ...TRANSMISSION 5 83...

Page 306: ...CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 67 CHECKING THE FUEL INJECTOR 8 68...

Page 321: ...CHARGING SYSTEM 8 15 EASB291338...

Page 325: ...COOLING SYSTEM For JPN 8 19 EASB291341...

Page 355: ...FUEL PUMP SYSTEM 8 49 EASB291348...

Page 356: ...ELECTRICAL COMPONENTS 8 50 ELECTRICAL COMPONENTS EASB291349 8 9 10 1 3 2 4 5 6 7...

Page 358: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 360: ...ELECTRICAL COMPONENTS 8 54 EASB291350 CHECKING THE SWITCHES 4 1 3 2 E B S E B E B E E B B...

Page 382: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...