FRONT FORK

4-42

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Remove:

• Base valve “1”

(from the damper assembly)

TIP

Hold the damper assembly with the cap bolt

ring wrench “2” and use the cap bolt wrench “3”

to remove the base valve.

EASB291176

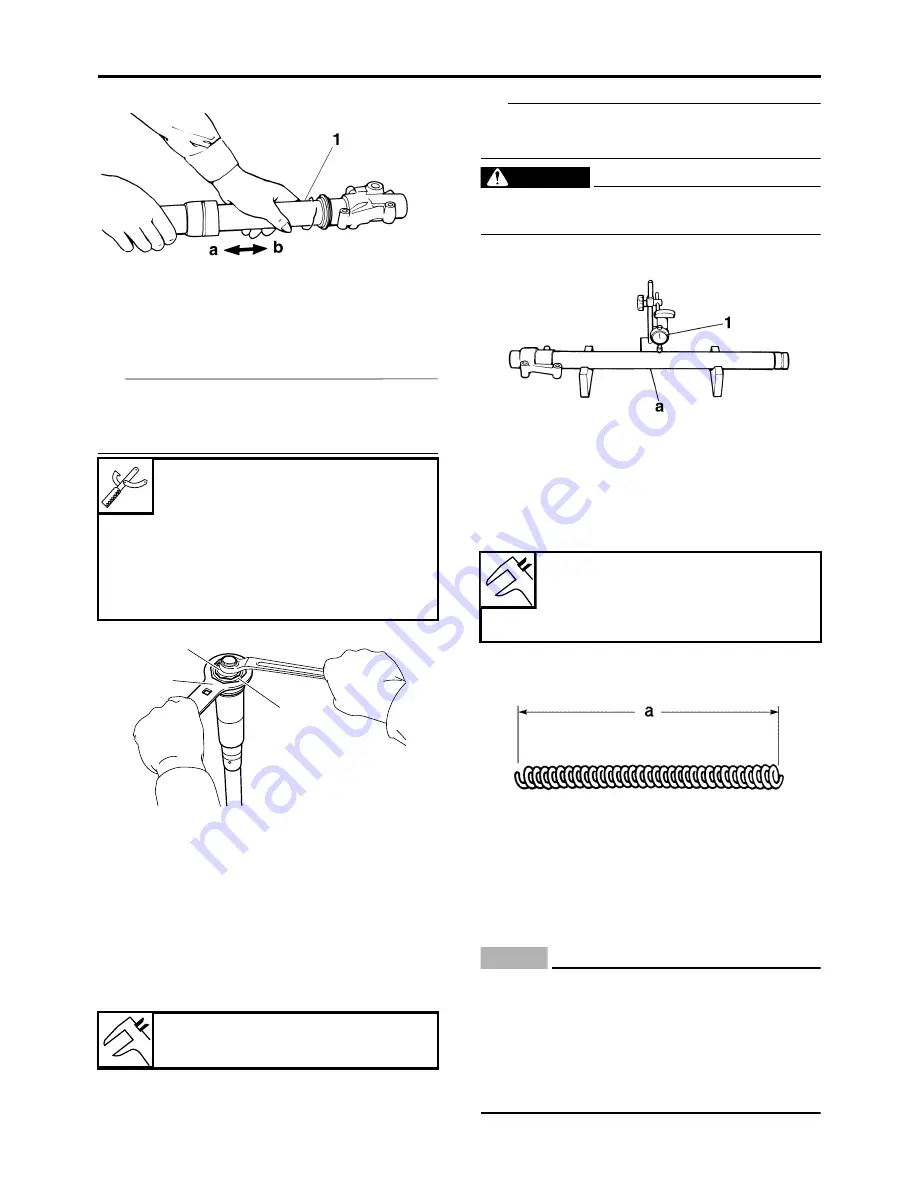

CHECKING THE FRONT FORK LEGS

1. Check:

• Inner tube surface “a”

Scratches

Repair or replace.

Use #1000 grit wet sandpaper.

Damaged oil lock piece

Replace.

• Inner tube bends

Out of specification

Replace.

Use the dial gauge “1”.

TIP

The bending value is shown by one half of the

dial gauge reading.

EWA

WARNING

Do not attempt to straighten a bent inner

tube as this may dangerously weaken it.

2. Check:

• Outer tube

Scratches/wear/damage

Replace.

3. Measure:

• Fork spring free length “a”

Out of specification

Replace.

4. Check:

• Damper assembly “1”

Bend/damage

Replace.

• O-ring “2”

Wear/damage

Replace.

ECA

NOTICE

• The front fork leg has a built-in damper ad-

justing rod and a very sophisticated inter-

nal construction, which are particularly

sensitive to foreign material.

• When disassembling and assembling the

front fork leg, do not allow any foreign ma-

terial to enter the front fork.

Cap bolt wrench

90890-01500

Cap bolt wrench

YM-01500

Cap bolt ring wrench

90890-01501

Cap bolt ring wrench

YM-01501

Inner tube bending limit

0.2 mm (0.01 in)

1

2

3

Fork spring free length

470.0 mm (18.50 in)

Limit

465.0 mm (18.31 in)

Summary of Contents for YZ 2015 Series

Page 6: ...EASB291006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 33: ...CONTROL FUNCTIONS 1 21 a 2...

Page 65: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22 EASB291066...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 72: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 74: ...CABLE ROUTING DIAGRAM 2 31 EASB291068 CABLE ROUTING DIAGRAM...

Page 76: ...CABLE ROUTING DIAGRAM 2 33...

Page 78: ...CABLE ROUTING DIAGRAM 2 35...

Page 80: ...CABLE ROUTING DIAGRAM 2 37...

Page 82: ...CABLE ROUTING DIAGRAM 2 39...

Page 84: ...CABLE ROUTING DIAGRAM 2 41...

Page 86: ...CABLE ROUTING DIAGRAM 2 43...

Page 88: ...CABLE ROUTING DIAGRAM 2 45...

Page 128: ...ELECTRICAL SYSTEM 3 38...

Page 200: ...CHAIN DRIVE 4 70...

Page 244: ...ELECTRIC STARTER 5 41...

Page 266: ...OIL PUMP AND BALANCER GEAR 5 63 c d 6 6 7 8 8 b...

Page 286: ...TRANSMISSION 5 83...

Page 306: ...CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 67 CHECKING THE FUEL INJECTOR 8 68...

Page 321: ...CHARGING SYSTEM 8 15 EASB291338...

Page 325: ...COOLING SYSTEM For JPN 8 19 EASB291341...

Page 355: ...FUEL PUMP SYSTEM 8 49 EASB291348...

Page 356: ...ELECTRICAL COMPONENTS 8 50 ELECTRICAL COMPONENTS EASB291349 8 9 10 1 3 2 4 5 6 7...

Page 358: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 360: ...ELECTRICAL COMPONENTS 8 54 EASB291350 CHECKING THE SWITCHES 4 1 3 2 E B S E B E B E E B B...

Page 382: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...