REAR WHEEL

4-8

EASB296135

REMOVING THE REAR WHEEL

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Remove:

• Rear wheel axle nut “1”

3. Loosen:

• Locknut “2”

4. Tighten:

• Adjusting bolt “3”

5. Remove:

• Rear wheel axle

• Rear wheel

TIP

• Push the rear wheel forward and remove the

drive chain from the rear wheel sprocket.

• Do not depress the brake pedal with the rear

wheel removed.

EASB296136

CHECKING THE REAR WHEEL

1. Check:

• Rear wheel axle

• Rear wheel

• Bearing

• Oil seals

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.

2. Check:

• Tire(s)

• Rear wheel

Damage/wear

Replace.

Refer to “CHECKING THE TIRES” on page

3-33 and “CHECKING THE WHEELS” on

page 3-34.

3. Check:

• Spokes

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.

4. Measure:

• Radial wheel runout

• Lateral wheel runout

Refer to “CHECKING THE FRONT WHEEL”

on page 4-4.

EASB296137

DISASSEMBLING THE REAR WHEEL

1. Remove:

• Oil seals

• Bearing

Refer to “DISASSEMBLING THE FRONT

WHEEL” on page 4-5.

EASB296138

CHECKING AND REPLACING THE REAR

WHEEL SPROCKET

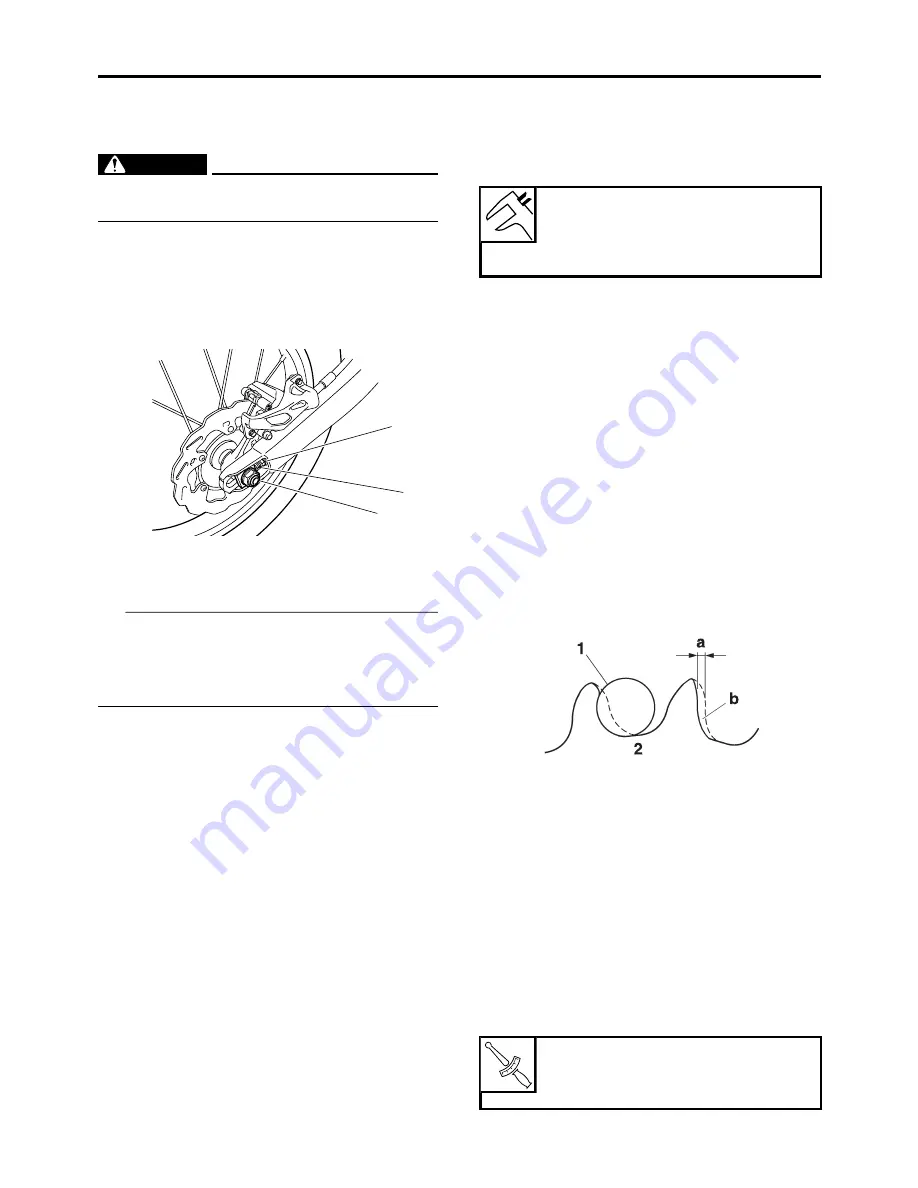

1. Check:

• Rear wheel sprocket

More than 1/4 tooth wear “a”

Replace the

rear wheel sprocket and the drive sprocket

as a set.

Bent tooth

Replace the rear wheel

sprocket and the drive sprocket as a set.

2. Replace:

• Rear wheel sprocket

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the self-locking nuts and the rear

wheel sprocket.

b. Clean the rear wheel drive hub with a clean

cloth, especially the surfaces that contact

the sprocket.

c. Install the new rear wheel sprocket.

3

1

2

Radial wheel runout limit

2.0 mm (0.08 in)

Lateral wheel runout limit

2.0 mm (0.08 in)

b. Correct

1. Drive chain roller

2. Rear wheel sprocket

Rear wheel sprocket self-locking

nut

50 Nm (5.0 m·kgf, 36 ft·lbf)

T

R

.

.

Summary of Contents for YZ 2016 Series

Page 6: ...EASB296006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 31: ...CONTROL FUNCTIONS 1 19 a 2...

Page 63: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 72: ...CABLE ROUTING DIAGRAM 2 31 EASB296066 CABLE ROUTING DIAGRAM...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 86: ...CABLE ROUTING DIAGRAM 2 45...

Page 262: ...OIL PUMP AND BALANCER GEAR 5 63 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 282: ...TRANSMISSION 5 83...

Page 302: ...8 CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 68 CHECKING THE FUEL INJECTOR 8 68...

Page 317: ...CHARGING SYSTEM 8 15...

Page 321: ...COOLING SYSTEM For JPN 8 19...

Page 351: ...FUEL PUMP SYSTEM 8 49...

Page 352: ...ELECTRICAL COMPONENTS 8 50 EASB296346 ELECTRICAL COMPONENTS EASB296347 7 8 9 1 3 2 4 5 6...

Page 354: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 356: ...ELECTRICAL COMPONENTS 8 54 EASB296348 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 378: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...