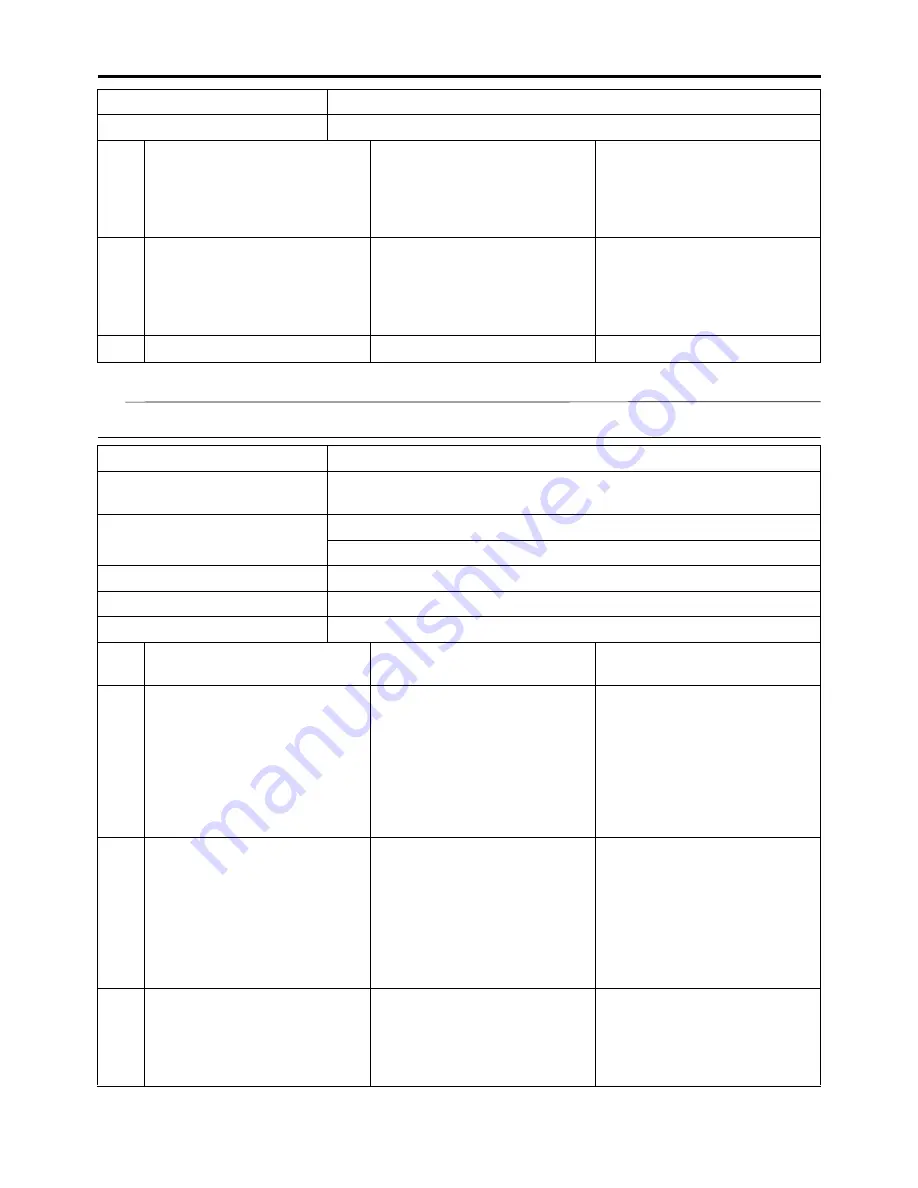

FUEL INJECTION SYSTEM

8-43

TIP

Before troubleshooting, disconnect the starter motor lead from the starter motor.

3

Wire harness continuity.

Open or short circuit

Re-

place the wire harness.

light green–light green

Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played

Go to item 4.

4

Yamaha diagnostic tool mal-

function.

Replace the Yamaha diag-

nostic tool.

Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played

Go to item 5.

5

Malfunction in ECU.

Replace the ECU.

Fault code No.

Er-2

Item

Signals from the ECU cannot be received within the specified

period of time.

Fail-safe system

Able to start engine

Able to drive vehicle

Diagnostic code No.

—

Diagnostic tool display

—

Procedure

—

Item Probable cause of malfunc-

tion and check

Maintenance job

Confirmation of service

completion

1

Connection of Yamaha diag-

nostic tool coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.

Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played

Go to item 2.

2

Connection of wire harness

ECU coupler.

Check the locking condition

of the coupler.

Disconnect the coupler and

check the pins (bent or bro-

ken terminals and locking

condition of the pins).

Improperly connected

Connect the coupler securely

or repair/replace the wire har-

ness.

Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played

Go to item 3.

3

Wire harness continuity.

Open or short circuit

Re-

place the wire harness.

light green–light green

Push the start switch.

Fault code number is not dis-

played

Service is finished.

Fault code number is dis-

played

Go to item 4.

Fault code No.

waiting for connection

Item

No communication signal is received from the ECU.

Summary of Contents for YZ 2016 Series

Page 6: ...EASB296006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 31: ...CONTROL FUNCTIONS 1 19 a 2...

Page 63: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 72: ...CABLE ROUTING DIAGRAM 2 31 EASB296066 CABLE ROUTING DIAGRAM...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 86: ...CABLE ROUTING DIAGRAM 2 45...

Page 262: ...OIL PUMP AND BALANCER GEAR 5 63 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 282: ...TRANSMISSION 5 83...

Page 302: ...8 CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 68 CHECKING THE FUEL INJECTOR 8 68...

Page 317: ...CHARGING SYSTEM 8 15...

Page 321: ...COOLING SYSTEM For JPN 8 19...

Page 351: ...FUEL PUMP SYSTEM 8 49...

Page 352: ...ELECTRICAL COMPONENTS 8 50 EASB296346 ELECTRICAL COMPONENTS EASB296347 7 8 9 1 3 2 4 5 6...

Page 354: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 356: ...ELECTRICAL COMPONENTS 8 54 EASB296348 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 378: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...