ELECTRICAL COMPONENTS

8-60

d. Adjust the voltage so that the current is at

the standard charging level.

e. Set the time according to the charging time

suitable for the open-circuit voltage.

f. If charging requires more than 5 hours, it is

advisable to check the charging current after

a lapse of 5 hours. If there is any change in

the amperage, readjust the voltage to obtain

the standard charging current.

g. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

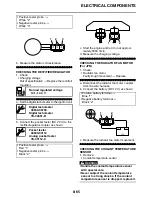

Charging method using a constant volt-

age charger

a. Measure the open-circuit voltage prior to

charging.

TIP

Voltage should be measured 30 minutes after

the engine is stopped.

b. Connect a charger and ammeter to the bat-

tery and start charging.

c. Make sure that the current is higher than the

standard charging current written on the bat-

tery.

TIP

If the current is lower than the standard charg-

ing current written on the battery, this type of

battery charger cannot charge the VRLA (Valve

Regulated Lead Acid) battery. A variable volt-

age charger is recommended.

d. Charge the battery until the battery’s charg-

ing voltage is 15 V.

TIP

Set the charging time at 20 hours (maximum).

e. Measure the battery open-circuit voltage af-

ter leaving the battery unused for more than

30 minutes.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

• Battery terminals

7. Connect:

• Battery leads

(to the battery terminals)

ECA

NOTICE

First, connect the positive battery lead “1”,

and then the negative battery lead “2”.

8. Check:

• Battery terminals

Dirt

Clean with a wire brush.

Loose connection

Connect properly.

9. Lubricate:

• Battery terminals

10.Install:

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

EASB296351

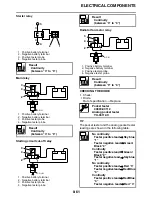

CHECKING THE RELAYS

Check each switch for continuity with the pock-

et tester. If the continuity reading is incorrect,

replace the relay.

1. Disconnect the relay from the wire harness.

2. Connect the pocket tester (

1) and bat-

tery (12 V) to the relay terminal as shown.

Check the relay operation.

Out of specification

Replace.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

12.8 V or more --- Charging is complete.

12.7 V or less --- Recharging is required.

Under 12.0 V --- Replace the battery.

Recommended lubricant

Dielectric grease

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

2

1

Summary of Contents for YZ 2016 Series

Page 6: ...EASB296006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 31: ...CONTROL FUNCTIONS 1 19 a 2...

Page 63: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 72: ...CABLE ROUTING DIAGRAM 2 31 EASB296066 CABLE ROUTING DIAGRAM...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 86: ...CABLE ROUTING DIAGRAM 2 45...

Page 262: ...OIL PUMP AND BALANCER GEAR 5 63 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 282: ...TRANSMISSION 5 83...

Page 302: ...8 CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 68 CHECKING THE FUEL INJECTOR 8 68...

Page 317: ...CHARGING SYSTEM 8 15...

Page 321: ...COOLING SYSTEM For JPN 8 19...

Page 351: ...FUEL PUMP SYSTEM 8 49...

Page 352: ...ELECTRICAL COMPONENTS 8 50 EASB296346 ELECTRICAL COMPONENTS EASB296347 7 8 9 1 3 2 4 5 6...

Page 354: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 356: ...ELECTRICAL COMPONENTS 8 54 EASB296348 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 378: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...