CHASSIS

10-2

• Under a stony or a hard road condition, the

tire pressure should be higher to prevent a flat

tire.

EASB29B391

FRONT FORK SETTING

The front fork setting should be made depend-

ing on the rider’s feeling of an actual run and

the circuit conditions.

The front fork setting includes the following

three factors:

1. Setting of air spring characteristics

• Change the fork oil amount.

2. Setting of spring preload

• Change the spring.

3. Setting of damping force

• Change the compression damping force.

• Change the rebound damping force.

The spring acts on the load and the damping

force acts on the cushion travel speed.

EASB29B392

CHANGE IN AMOUNT AND CHARACTERIS-

TICS OF FORK OIL

Damping characteristic near the final stroke

can be changed by changing the fork oil

amount.

EWA

WARNING

Adjust the oil amount in 5 cm

3

(0.2 US oz,

0.2 Imp.oz) increments or decrements. Too

small oil amount causes the front fork to

produce a noise at full rebound or the rider

to feel some pressure on his hands or body.

Alternatively, too large oil amount will

cause the air spring characteristics to have

a tendency to be stiffer with the consequent

deteriorated performance and characteris-

tics. Therefore, adjust the front fork within

the specified range.

EASB29B393

SETTING OF SPRING AFTER REPLACE-

MENT

As the front fork setting can be easily affected

by the rear suspension, take care so that the

front and the rear are balanced (in position etc.)

when setting the front fork.

1. Use of soft spring

• Change the rebound damping force.

Turn out one or two clicks.

• Change the compression damping force.

Turn in one or two clicks.

TIP

Generally a soft spring gives a soft riding feel-

ing. Rebound damping tends to become stron-

ger and the front fork may sink deeply over a

series of gaps.

2. Use of stiff spring

• Change the rebound damping force.

Turn in one or two clicks.

• Change the compression damping force.

Turn out one or two clicks.

Extent of adjustment

100–120 kPa (1.00–1.20 kgf/cm

2

,

15–18 psi)

Standard oil amount

330 cm

3

(11.16 US oz, 11.64

lmp.oz)

Extent of adjustment

300–365 cm

3

(10.14–12.34 US

oz, 10.58–12.87 Imp.oz)

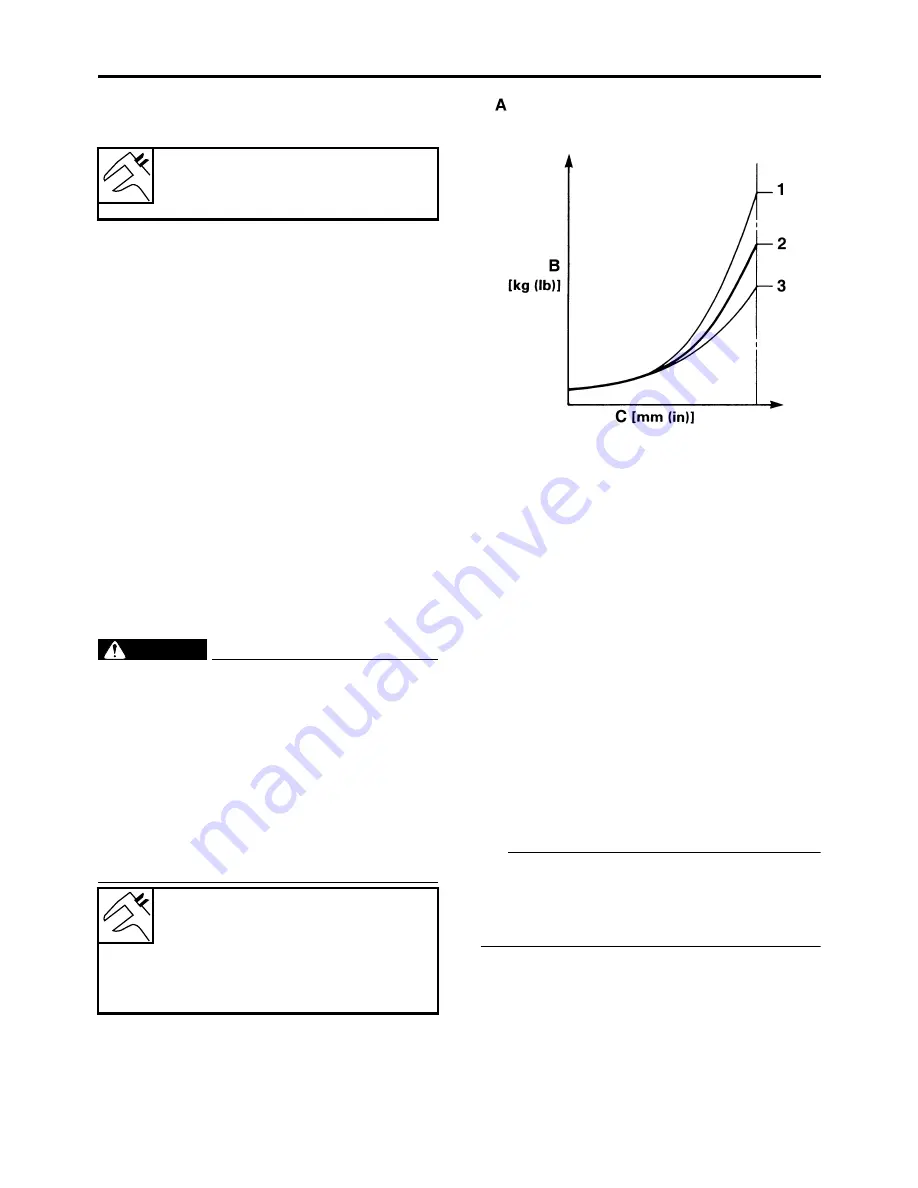

A. Air spring characteristics in relation to oil

amount change

B. Load

C. Stroke

1. Max. oil amount

2. Standard oil amount

3. Min. oil amount

Summary of Contents for YZ 2018 Series

Page 6: ...EASB916006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 40: ...MOTORCYCLE CARE AND STORAGE 1 28...

Page 64: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 23...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...CABLE ROUTING DIAGRAM 2 29 EASB29B065 CABLE ROUTING DIAGRAM...

Page 72: ...CABLE ROUTING DIAGRAM 2 31...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 255: ...OIL PUMP AND BALANCER GEAR 5 58 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 276: ...TRANSMISSION 5 79...

Page 290: ...FUEL TANK 7 5 A Left B Right 1 1 A 0 mm 0 in B 1 1 15 mm 0 59 in...

Page 296: ...THROTTLE BODY 7 11...

Page 299: ......

Page 313: ...CHARGING SYSTEM 8 14...

Page 321: ...COOLING SYSTEM For JPN 8 22...

Page 351: ...FUEL PUMP SYSTEM 8 52 EASB29B345...

Page 352: ...ELECTRICAL COMPONENTS 8 53 ELECTRICAL COMPONENTS EASB29B346 9 10 11 1 3 2 4 5 6 7 8...

Page 354: ...ELECTRICAL COMPONENTS 8 55 11 10 9 2 3 1 6 7 8 4 5...

Page 356: ...ELECTRICAL COMPONENTS 8 57 EASB29B347 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 372: ...ELECTRICAL COMPONENTS 8 73 c Measure the fuel injector resistance...