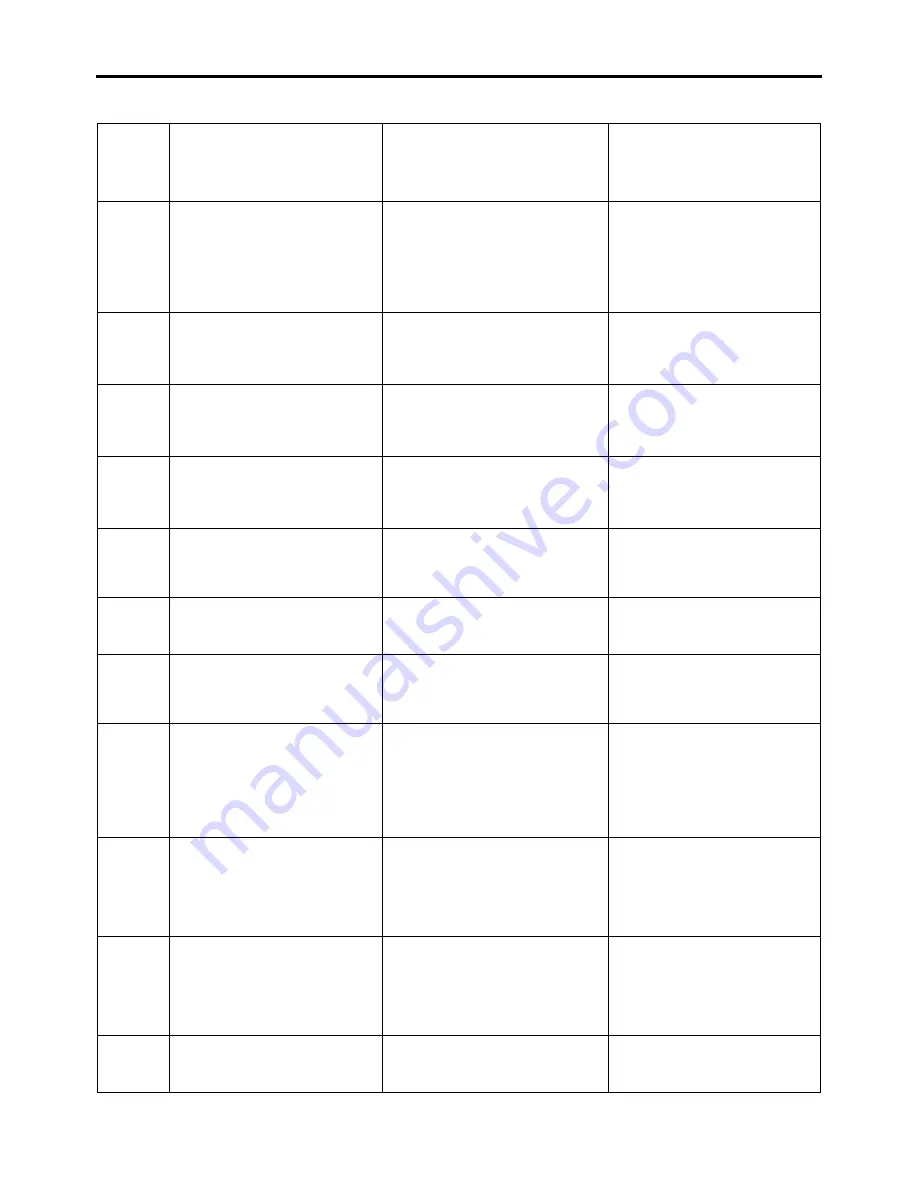

LIST OF SELF-DIAGNOSTIC AND FAIL-SAFE ACTIONS

9-5

EAM30367

SENSOR OPERATION TABLE

Diag-

nostic

code

No.

Item

Display

Procedure

01

Throttle position sensor signal

•

Fully closed position

•

11–14

•

Check with throttle valve

fully closed.

•

Fully opened position

•

109–116

•

Check with throttle valve

fully open.

03

Intake air pressure

Displays the intake air pressure. Operate the throttle while

pushing the start switch. (If

the display value changes, the

performance is OK.)

05

Intake air temperature

Displays the intake air tempera-

ture.

Compare the actually mea-

sured intake air temperature

with the Yamaha diagnostic

tool display value.

06

Coolant temperature

Displays the coolant tempera-

ture.

Compare the actually mea-

sured coolant temperature

with the Yamaha diagnostic

tool display value.

08

Lean angle sensor

Displays the output voltage.

Remove the lean angle sen-

sor, and incline it more than

45 degrees.

•

Upright

•

Overturned

•

0.4–1.4

•

3.7–4.4

09

Monitor voltage

Displays the fuel system volt-

age.

•

Approximately 12.0 (V)

—

21

Neutral switch

Operate the shift pedal.

•

Gear in neutral

•

Gear not in neutral

•

ON

•

OFF

60

EEPROM fault code display

—

•

No fault

•

CO adjustment value

•

Setting tool adjustment val-

ues 0–8 for fuel injection

amount or ignition timing

•

00

•

01

•

07

61

Malfunction history (

) code

display *1

—

•

There is no history.

•

There is some history.

•

00

•

Other: Displays the fault code

of (

).

62

Malfunction history (

) code

erasure *1

Replace all (

) with (

) by

the operation start process-

ing.

•

There is no history.

•

There is some history.

•

00

•

Other: Displays the total num-

ber of (

) and (

).

64

Setting history display

Displays the presence or

absence of the setting history by

Power Tuner.

—

Summary of Contents for YZ 2019 Series

Page 6: ...EAM20162 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 40: ...MOTORCYCLE CARE AND STORAGE 1 28...

Page 63: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 72: ...CABLE ROUTING DIAGRAM 2 31 EAM20152 CABLE ROUTING DIAGRAM...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 86: ...CABLE ROUTING DIAGRAM 2 45...

Page 126: ...ELECTRICAL SYSTEM 3 38...

Page 177: ...FRONT FORK 4 49 1...

Page 196: ...CHAIN DRIVE 4 68...

Page 217: ...CAMSHAFT 5 18 Spark plug Spark plug 13 N m 1 3 kgf m 9 6 lb ft T R...

Page 237: ...ELECTRIC STARTER 5 38...

Page 256: ...OIL PUMP AND BALANCER GEAR 5 57 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 262: ...GENERATOR AND STARTER CLUTCH 5 63 1 a 3 3 2 4...

Page 276: ...TRANSMISSION 5 77...

Page 284: ...WATER PUMP 6 7...

Page 290: ...FUEL TANK 7 5 A Left B Right 1 1 A 0 mm 0 in B 1 1 15 mm 0 59 in...

Page 296: ...THROTTLE BODY 7 11...

Page 299: ......

Page 313: ...CHARGING SYSTEM 8 14...

Page 343: ...FUEL INJECTION SYSTEM 8 44...

Page 347: ...FUEL PUMP SYSTEM 8 48...

Page 348: ...ELECTRICAL COMPONENTS 8 49 EAM20147 ELECTRICAL COMPONENTS 9 10 1 3 2 4 5 6 7 8...

Page 350: ...ELECTRICAL COMPONENTS 8 51 11 10 9 2 3 1 6 7 8 4 5...

Page 352: ...ELECTRICAL COMPONENTS 8 53 EAM30289 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 368: ...ELECTRICAL COMPONENTS 8 69...

Page 376: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...