7-21

SETTING

TUN

c

C

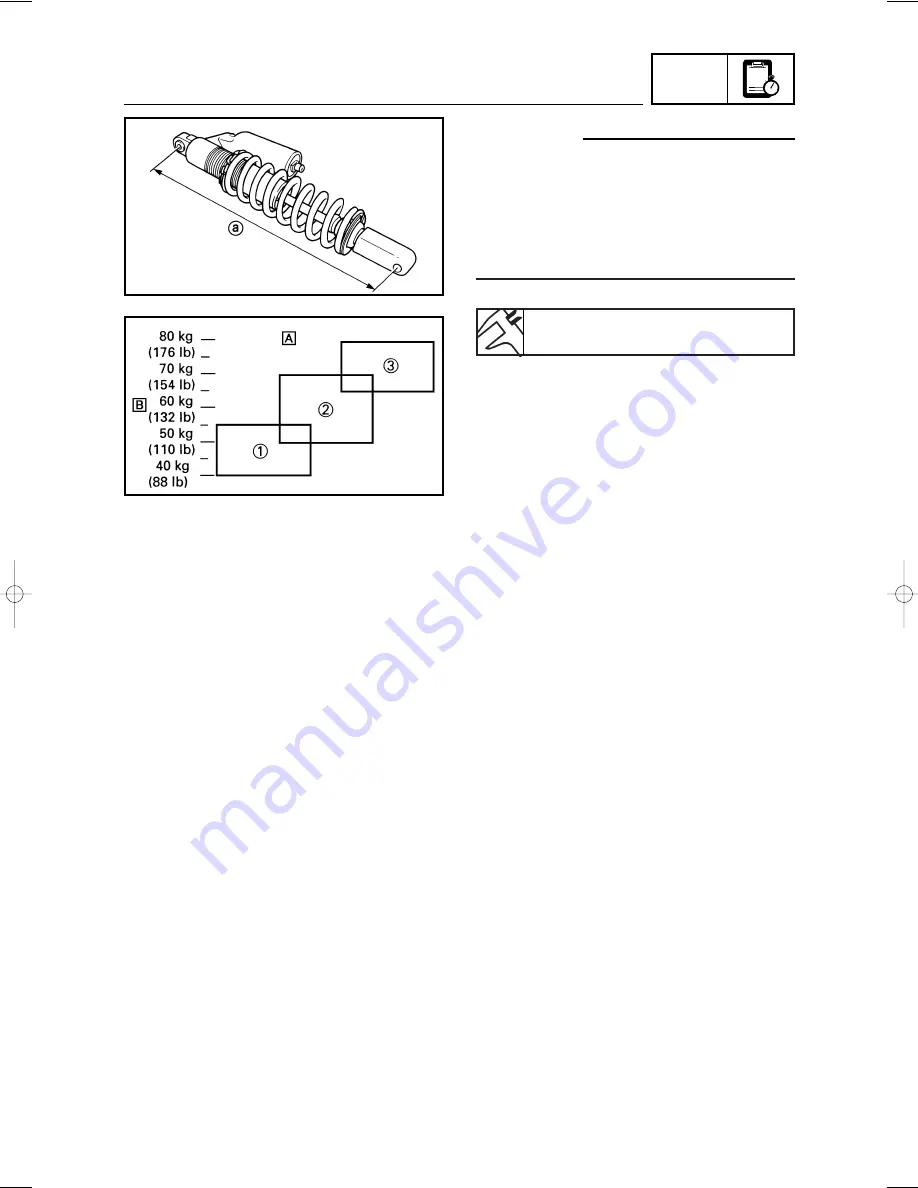

When using a rear cushion other than cur-

rently installed, use the one whose overall

length

a

a

does not exceed the standard as

it may result in faulty performance. Never

use one whose overall length is greater

than standard.

å

Coverage of spring by weight

∫

Rider weight

1

Soft

2

Standard

3

Stiff

Length

a

a

of standard shock:

490.5 mm (19.31 in)

5NX-9-30-7 6/5/01 4:48 PM Page 46

Summary of Contents for YZ250(P)/LC

Page 2: ......

Page 128: ...3 3 INSP ADJ MEMO...

Page 582: ...TUN MEMO...

Page 583: ......

Page 584: ......