5-22

FRONT FORK

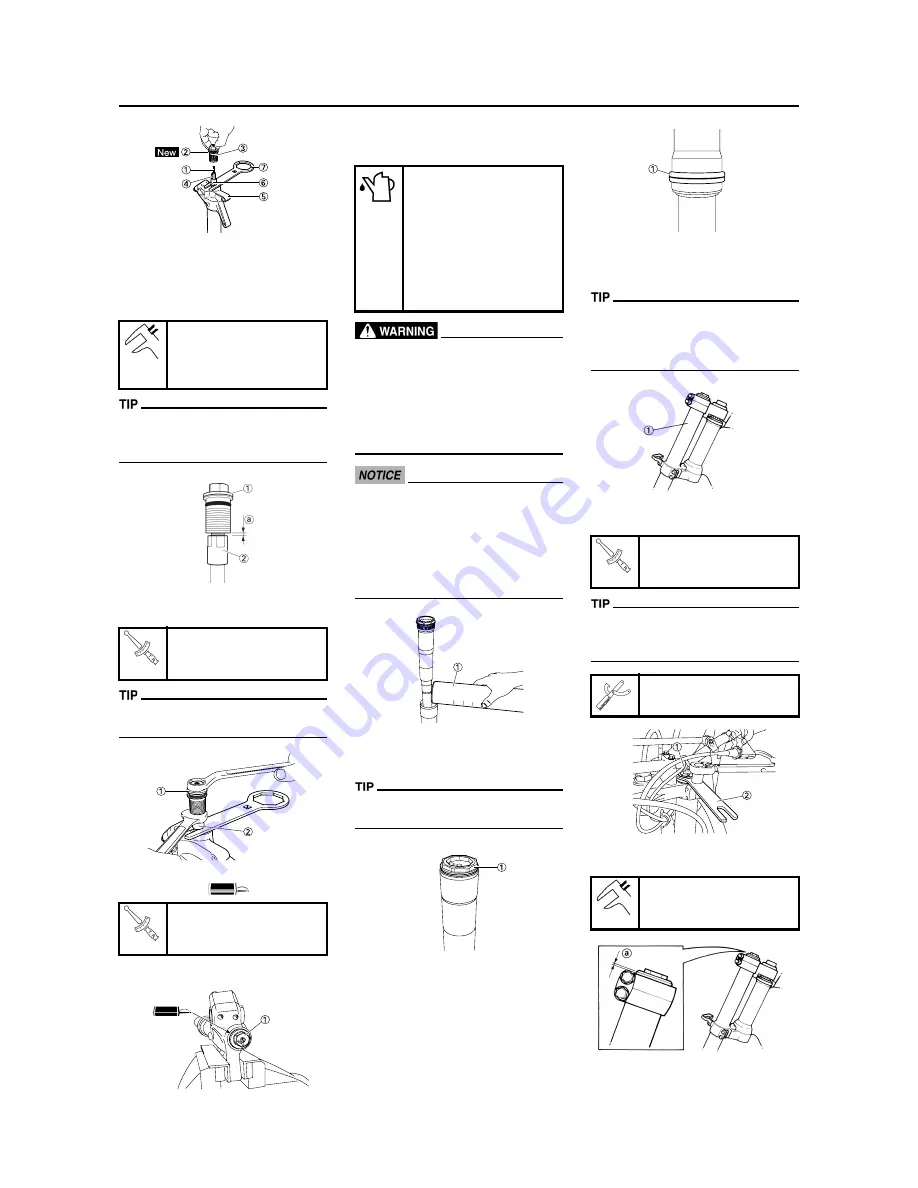

28. Inspect:

• Gap "a" between the adjuster "1"

and locknut "2".

Out of specification

→

Retighten

and readjust the locknut.

If the adjuster is installed out of spec-

ification, proper damping force can-

not be obtained.

29. Tighten:

• Adjuster (locknut) "1"

Hold the locknut "2" and tighten the

adjuster with specified torque.

30. Install:

• Adjuster "1"

To inner tube.

31. Fill:

• Front fork oil "1"

From outer tube top.

Never fail to make the oil amount

adjustment between the maximum

and minimum amount and always

adjust each front fork to the same

setting. Uneven adjustment can

cause poor handling and loss of

stability.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

32. Install:

• Damper assembly "1"

To outer tube.

Temporarily tighten the damper as-

sembly.

33. Install:

• Protector guide "1"

INSTALLING THE FRONT FORK

1. Install:

• Front fork "1"

• Temporarily tighten the pinch bolts

(lower bracket).

• Do not tighten the pinch bolts (up-

per bracket) yet.

2. Tighten:

• Damper assembly "1"

Use the cap bolt ring wrench "2" to

tighten the damper assembly with

specified torque.

3. Adjust:

• Front fork top end "a"

Gap "a" between the ad-

juster and locknut:

0.5–1.0 mm (0.02–0.04

in)

Adjuster (locknut):

29 Nm (2.9 m•kg, 21

ft•lb)

Adjuster:

55 Nm (5.5 m•kg, 40

ft•lb)

Recommended oil:

Suspension oil "S1"

Standard oil amount:

330 cm

3

(11.6 Imp oz,

11.2 US oz)

Extent of adjustment:

300–375 cm

3

(10.6–13.2 Imp oz,10.1–

12.7 US oz)

Damper assembly:

30 Nm (3.0 m•kg, 22

ft•lb)

Cap bolt ring wrench:

YM-01501/90890-01501

Front fork top end (stan-

dard) "a":

5 mm (0.20 in)