2-21

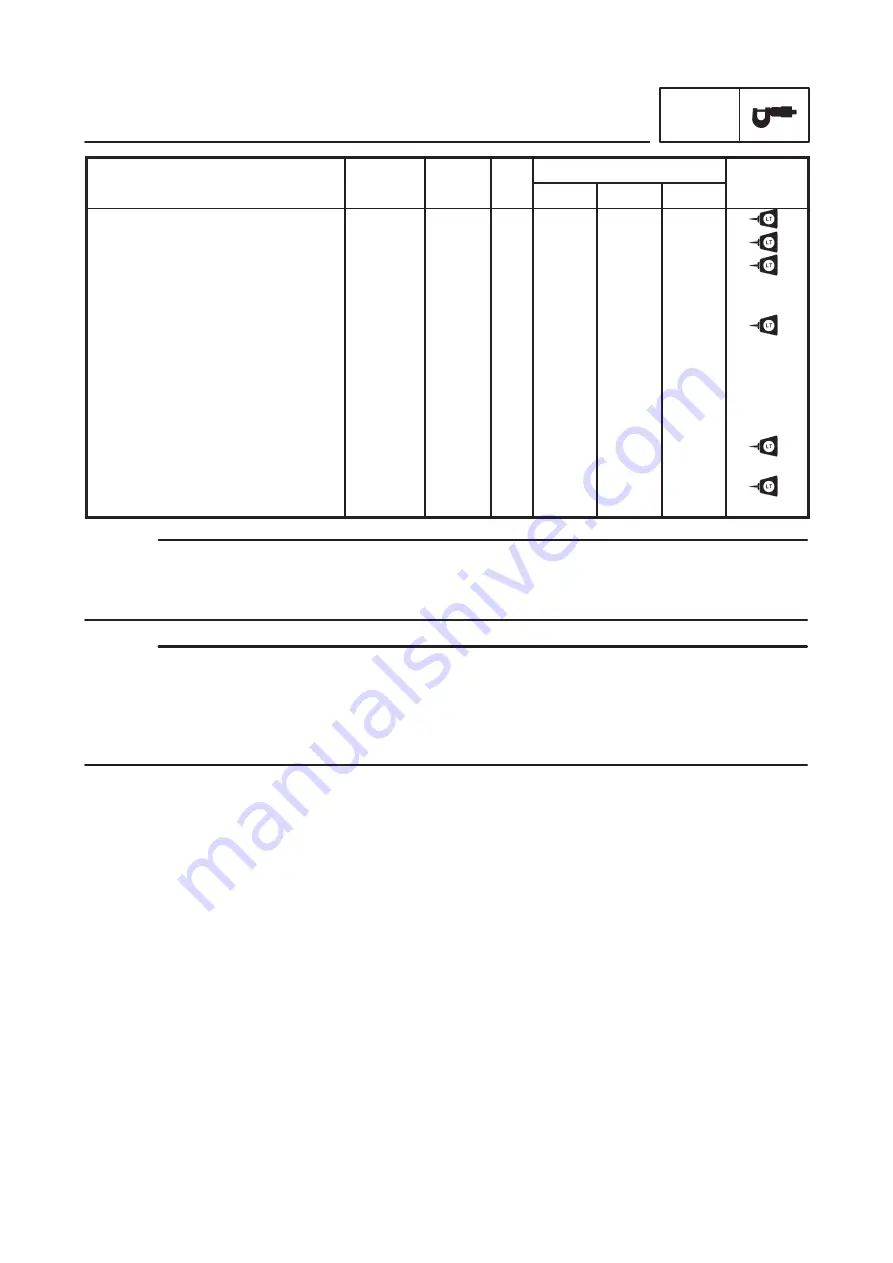

TIGHTENING TORQUES

SPEC

NOTE 1:

NOTE 2:

Item

Fastener

Thread

Q’ty

Tightening torque

Remarks

Item

Fastener

size

Q ty

Nm

m

S

kg

ft

S

lb

Remarks

Main axle bearing housing

Bolt

M6

3

12

1.2

8.7

Shift fork shaft stopper

Bolt

M6

2

10

1.0

7.2

Stopper screw

Screw

M8

1

22

2.2

16

Shift rod lock nut (rear)

Nut

M6

1

7

0.7

5.0

Left thread

Shift rod lock nut (front)

Nut

M6

1

7

0.7

5.0

Shift rod joint

Bolt

M6

1

10

1.0

7.2

Shift arm

Bolt

M6

1

10

1.0

7.2

E.C.U.

Screw

M6

2

7

0.7

5.0

Neutral switch

—

M10

1

20

2.0

15

EXUP servo motor cover

Screw

M5

2

2

0.2

1.5

Coolant temperature sensor

—

M12

1

18

1.8

13

Cylinder identification sensor

Bolt

M6

1

8

0.8

5.7

Atmospheric pressure sensor

Screw

M5

2

7

0.7

5.0

Crankshaft position sensor

Bolt

M6

1

10

1.0

7.2

Oil level switch

Bolt

M6

2

10

1.0

7.2

1. First, tighten the bolts to approximately 19 Nm (1.9 m

S

kg, 14 ft

S

lb) with a torque wrench following the

tightening order.

2. Retighten the bolts 67 Nm (6.7 m

S

kg, 48 ft

S

lb) with a torque wrench.

1. First, tighten the bolts to approximately 20 Nm (2.0 m

S

kg, 15 ft

S

lb) with a torque wrench following the

tightening order.

2. Loosen the all bolts one by one following the tightening order and then tighten them to 20 Nm (2.7

m

S

kg, 15 ft

S

lb) again.

3. Retighten the bolts further to reach the specified angle (60

_

).

22

Summary of Contents for YZF-R1 2004

Page 1: ...Yamaha Motor Co Ltd 2004 YZF R1 S 5VY1 SE1 SERVICE INFORMATION ...

Page 50: ...YZF R1 S 2004 WIRING DIAGRAM ...

Page 51: ......