6D03F1X

58

NOTE:

“P” is the deviation of the lower case dimen-

sion from standard. The “P” mark

a

is

stamped on the trim tab mounting surface of

the lower case in 0.01 mm units. If the “P”

mark is unreadable, assume that “P” is zero

and check the backlash when the unit is

assembled.

Example:

If “M3” is 50.75 mm and “M4” is 30.52 mm

and “P” is (–5), then

T3 = 82.00 + (–5)/100 – 50.75 – 30.52 mm

= 82.00 – 0.05 – 50.75 – 30.52 mm

= 0.68 mm

6.

Select the pinion shim(s) (T3) as follows.

Example:

If “T3” is 0.68 mm, then the pinion shim is

0.65 mm.

If “T3” is 0.70 mm, then the pinion shim is

0.68 mm.

Backlash

(counter rotation model)

6

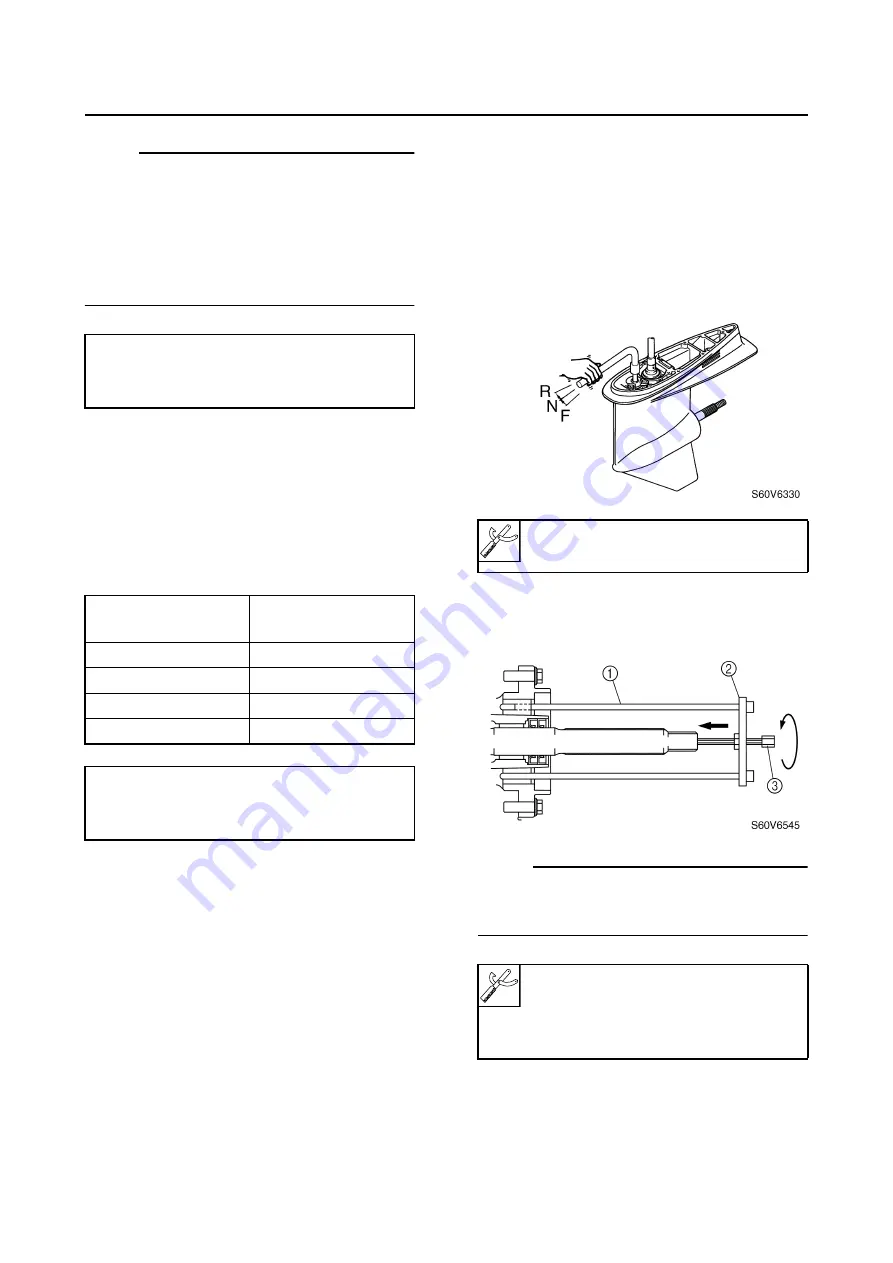

Measuring the forward and reverse

gear backlash

1.

Remove the water pump assembly.

2.

Set the gear shift to the neutral position

at the lower unit.

3.

Install the special service tools so that it

pushes against the propeller shaft.

NOTE:

Tighten the center bolt while turning the drive

shaft until the drive shaft can no longer be

turned.

4.

Install the backlash indicator onto the

drive shaft (22.4 mm [0.88 in] in diame-

ter), then the dial gauge onto the lower

unit.

Calculation formula:

Pinion shim thickness (T3) =

82.00 + P/100 – M3 – M4

Calculated numeral

at 1/100 place

Rounded numeral

1, 2

0

3, 4, 5

2

6, 7, 8

5

9, 10

8

Available shim thicknesses:

0.10, 0.12, 0.15, 0.18, 0.30, 0.40, and

0.50 mm

Shift rod push arm: 90890-06052

Bearing housing puller claw L

1

:

90890-06502

Stopper guide plate

2

: 90890-06501

Center bolt

3

: 90890-06504

Shimming (counter rotation model) / Backlash (counter rotation model)