7

Ⅳ . SETTING OF PRESSURE

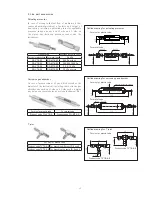

1. Switch contact confi guration

・ Composition of contact of this instrument is as shown on

the right.

・ If the instrument is not applied by differential pressure we

call such “

normal condition

” .

・ At normal condition, the contact between COM. and N.C.

is closed, and between COM. and N.O. is open.

・ With increase of differential pressure and reaching the actuation pressure, the contact will be changed

over ; between COM. and N.C. is opened and between COM. and N.O. is closed.

2. Setting of upper limit/ lower limit

・ When differential pressure applied to the instrument is

increased starting from zero and changes over the electric

contact from N.C. (normal close) to N.O. (normal open), the

pressure at this moment is called “

actuation pressure

” .

・ When this differential pressure decreases from the pressure

higher than this actuation pressure activating electrical

contact and returning the contact from N.O. (normal open)

to N.C. (normal close), the pressure at this moment is called

“

reset pressure

” .

・ There is certain difference between actuation pressure and reset pressure and this is called “

dead band

” .

・ There are two types of the instrument. One is called “

upper limit setting type

” type (H) whose scale of

setting knob is adjusted on actuation pressure, the other is called “

lower limit setting type

” type (L)

which is adjusted on reset pressure.

・ Be careful about the difference between the upper and lower limit setting switched and also understand

the relation between the pressure increase/ decrease and the contact composition before designing the

operational sequence.

Depending on the purpose of use, choose the instrument

either

“upper limit setting type”

or

“lower limit setting type”

Difference of contact movement between

“upper limit setting type” and “lower limit

setting type”

In case of 1-6 kPa range with set value 2 kPa.

(dead band is 0.6 kPa)

Adjusting of scale

Name plate

Upper limit

setting type

Adjusted in

activating pressure

In case of “upper limit setting type”

When the differential pressure increases, the

circuit is closed between N.O. and COM. at

2 kPa.

Then as the differential pressure decreases,

the circuit is opened between N.O. and

COM. at 1.4 kPa.

Lower limit

setting type

Adjusted in

reset pressure

In case of “lower limit setting type”

When the differential pressure increases, the

circuit is closed between N.O. and COM. at

2.6 kPa.

Then as the differential pressure decreases,

the circuit is opened between N.O. and

COM. at 2 kPa.

The scale of the setting knob is adjusted for both upper and lower limit setting type at our factory before

shipping. It is not allowed for customers to convert from the upper limit setting to the lower limit setting or

vice versa.

ᵢᶇᶄᶄᶃᶐᶃᶌᶒᶇᵿᶊᴾᶎᶐᶃᶑᶑᶓᶐᶃ

ᵟᶁᶒᶓᵿᶒᶇᶍᶌᴾᶎᶐᶃᶑᶑᶓᶐᶃ

ᵰᶃᶑᶃᶒᴾᶎᶐᶃᶑᶑᶓᶐᶃ

ᵱᶕᶇᶒᶁᶆᶇᶌᶅᴾᶂᶇᶄᶄᶃᶐᶃᶌᶁᶃ

ᵆᶂᶃᵿᶂᴾᶀᵿᶌᶂᵇ

ᵲᶇᶋᶃ

㻱㼤㼜㼘㼍㼚㼍㼠㼕㼛㼚㻌㼐㼕㼍㼓㼞㼍㼙㻌㼛㼒

㼟㼣㼕㼠㼏㼔㼕㼚㼓㻌㼐㼕㼒㼒㼑㼞㼑㼚㼏㼑㻌㼜㼞㼑㼟㼟㼡㼞㼑

ᾝᵌᾒᵌ

ᾒᾞᾜᵌ

ᾝᵌᾞᵌ

ᵧᶌᶁᶐᶃᵿᶑᶃᴾᶍᶄ

ᶂᶇᶄᶄᶃᶐᶃᶌᶒᶇᵿᶊ

ᶎᶐᶃᶑᶑᶓᶐᶃ