10. Be certain that exhaust pipe is flush with lower unit.

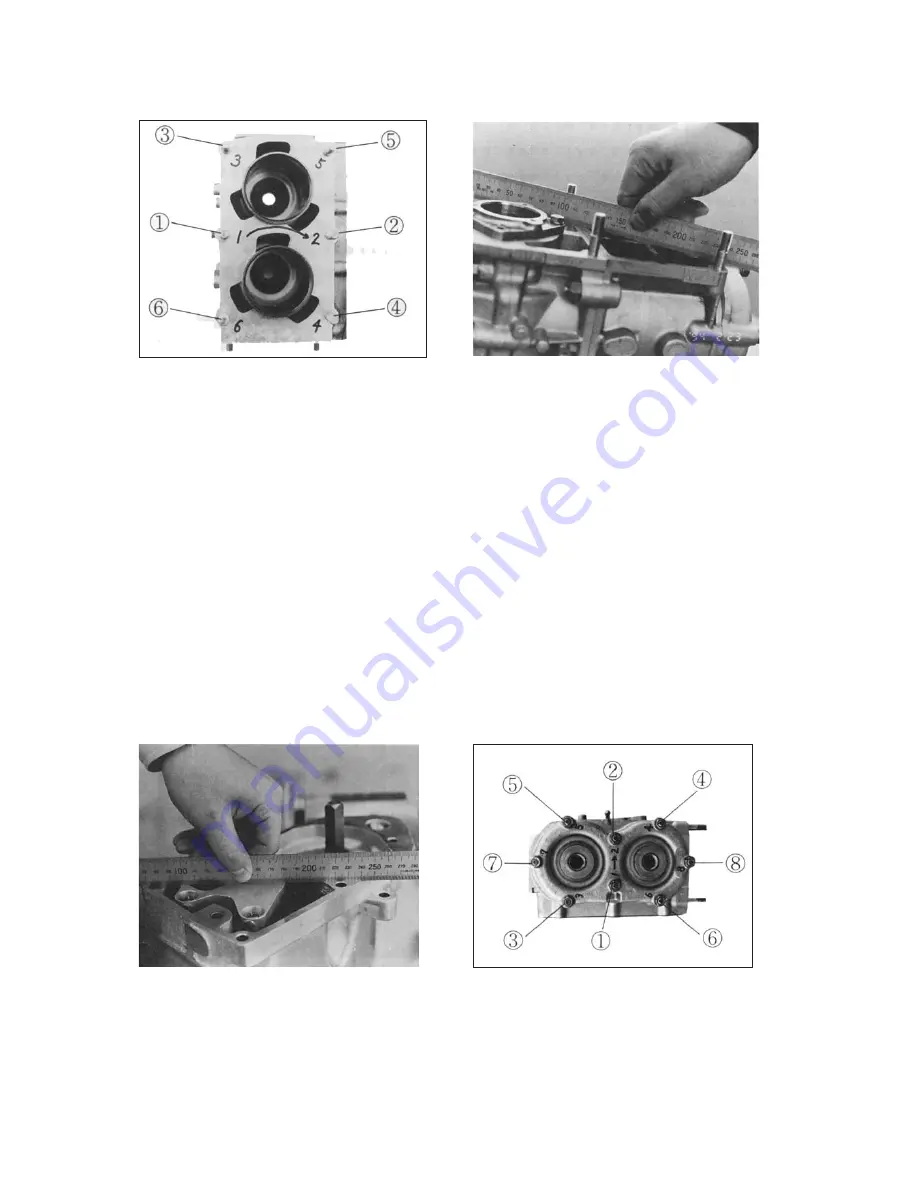

See figure 9.

11. Torque cylinder head 20 ~ 24 Nm (200 ~ 250 kg cm / 14 ~ 18 ft lbs).

See figure

10

for proper sequence. CAUTION: It is of utmost importance that all bolts and

nuts be torqued as specified. Over-tightening can cause distortion with notice-

able loss of power.

– 10 –

Figure 7

Figure 8

Figure 9

Figure 10

Summary of Contents for 302

Page 1: ...302 YAMATO MOTOR CO LTD Ota Japan November 2012 M O D E L M A N U A L ...

Page 2: ...YAMATO EUROpE www YamatoRacing co uk ...

Page 14: ... 11 pOWER UNIT GROUp ...

Page 15: ...pOWER UNIT GROUp 12 ...

Page 18: ... 15 MAGNETO GROUp ...

Page 19: ... 16 CARBURETTOR GROUp ...

Page 23: ... 20 LOWER UNIT GROUp ...

Page 24: ... 21 LOWER UNIT GROUp ...

Page 25: ...GEAR CASE GROUp 22 ...

Page 26: ... 23 FUEL TANK GROUp ...

Page 27: ... 24 IV TROUBLESHOOTING ...

Page 28: ... 25 V CROSS SECTION OF MOTOR ...