28

5.How to use the function menu (MODE key)

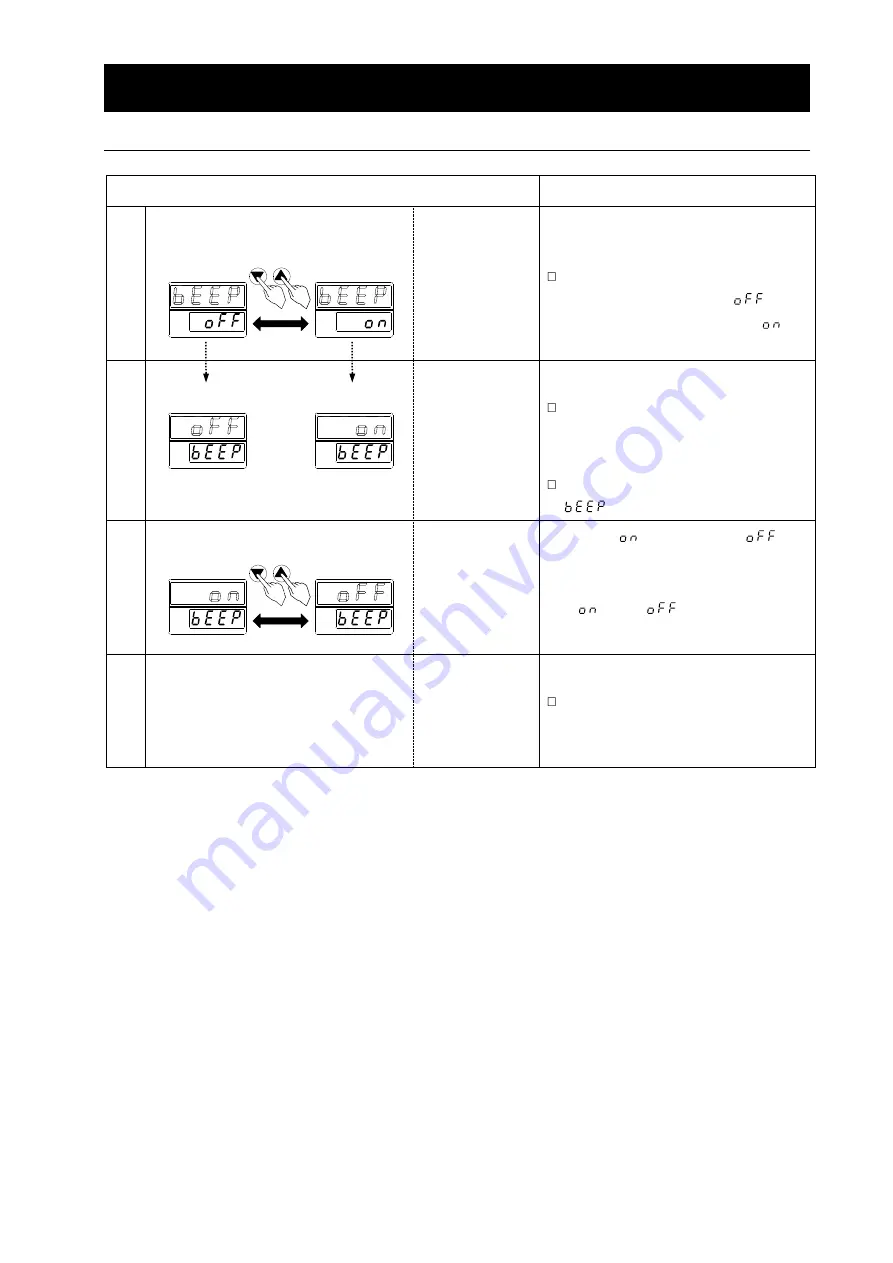

Setting and cancelling the error beep

Display after operation and operating procedures

Description

1

Select a function

(

See P.23

”Menu

c

ontents”.

)

Call for the “error beep” select mode

using the MODE.

The sub display indicates the present

beep setting. Indication of

means the disabled status and

means the enabled status.

2

Press the

[ENTER] key.

Press the [ENTER] key.

The mode changes to the

setting/cancelling mode for the error

beep.

Indication in the sub display changes to

.

3

Press the [

▼

] or

the [

▲

] key.

Select [

] to enable and [

] to

disable.

Press the [▼] or the [▲] key to flash

[

] and [

] alternately.

4

〈

Indication immediately before the MODE

key is pressed

〉

Press the

[ENTER] key.

Press the [ENTER] key.

Indication will return to the status

immediately before the [MODE] key is

pressed.

To disable

To enable

Indication when

the beep is

enabled

Indication when

the beep is

disabled