12

AZ-SD, AZF-G/BT43

3.Proper operation

3.3 Adjustment at beginning of sewing

Fig. 3-3

Fig. 3-4

Fig. 3-5

lighted

lighted

3.3.2 Stitch plate tongue adjustment at beginning of sewing

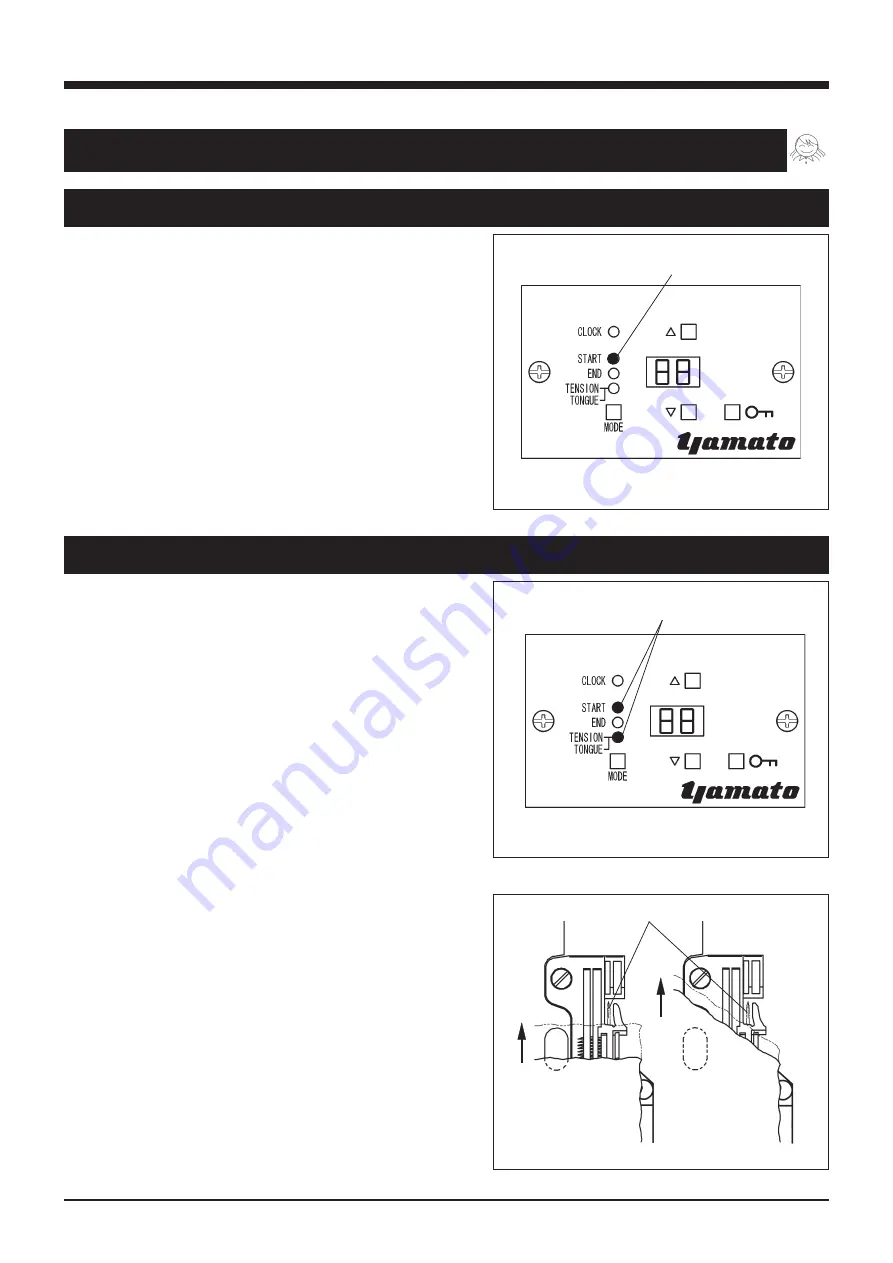

3.3.1 Tension releaser adjustment at beginning of sewing

(1) Press the “MODE”

key several times to ligh

the

“START”

and

“TONGUE”

lamps.

(2)

Adjust the count by pressing the “▲” and “▼”

keys so that the stitch plate tongue sticks

out when the sensor detects the material end

and the material reaches the needle holes.

(Two counts indicate one stitch.)

(1) Press the “MODE”

key several times to light

the

“START”

lamp only.

(2)

Adjust the count by pressing the “▲” and

“▼” keys so that the tension releaser changes

the thread chain seam condition to the plain

sewing seam condition when the sensor detects

the material end and the material reaches

the needle holes. (Two counts indicate one

stitch.)

tongue sticks out