18

AZ-SD, AZF-G/BT43

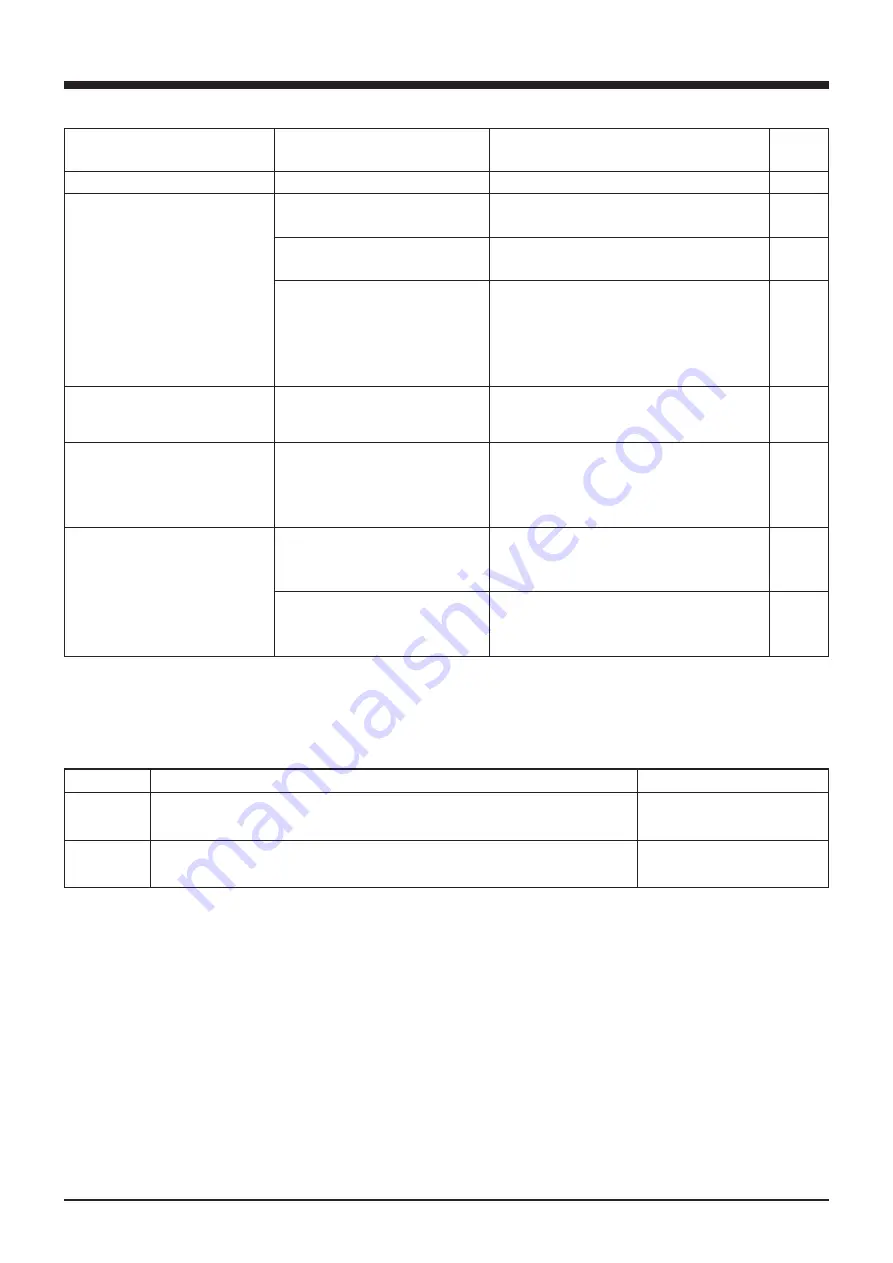

Error code

Causes

Measures

ES

The tension releaser or the stitch plate tongue cannot be moved.

The control board is broken.

Change the control

board.

EE

Resetting to the default setting cannot be performed.

There is an abnormal state in the memory.

Change the control

board.

Table 4

5.

Troubleshooting

Malfunctions

Causes

Measures

Refer

to

Thread chains are not cut. The knife is dull.

Change the knife.

4-2

Thread chains are not sewn

into seams.

A thread chain does not

form a cord.

Loosen the thread chain seam

condition.

3-1-1

Thread chains are pulled

out too early.

Increase the holding pressure.

4-1

Thread chains are not

completely pulled out of

the stitch plate tongue.

Increase each count at the beginning

of sewing so that the stitch plate

tongue or the tension releaser

functions when materials come at the

needle drop.

3-3

The thread tension at the

beginning of sewing is too

high.

The thread chain holding

pressure is too high.

Decrease the holding pressure.

4-1

Changing of the thread

chain seam condition is

unstable at the end of

sewing.

The setting for mesh

materials is valid.

Set the mesh count to zero.

3-5

Seams at the of sewing are

irregular.

Changing to the plain sewing

condition is delayed.

Decrease the value for the tension

releaser at the beginning of sewing.

3-3-1

Sticking out of the stitch

plate tongue is delayed.

Decrease the value for the stitch

plate tongue at the beginning of

sewing.

3-3-2

Error indication on the control panel

Table 5 Note: After the above error code is displayed, the control box does not operate.