41

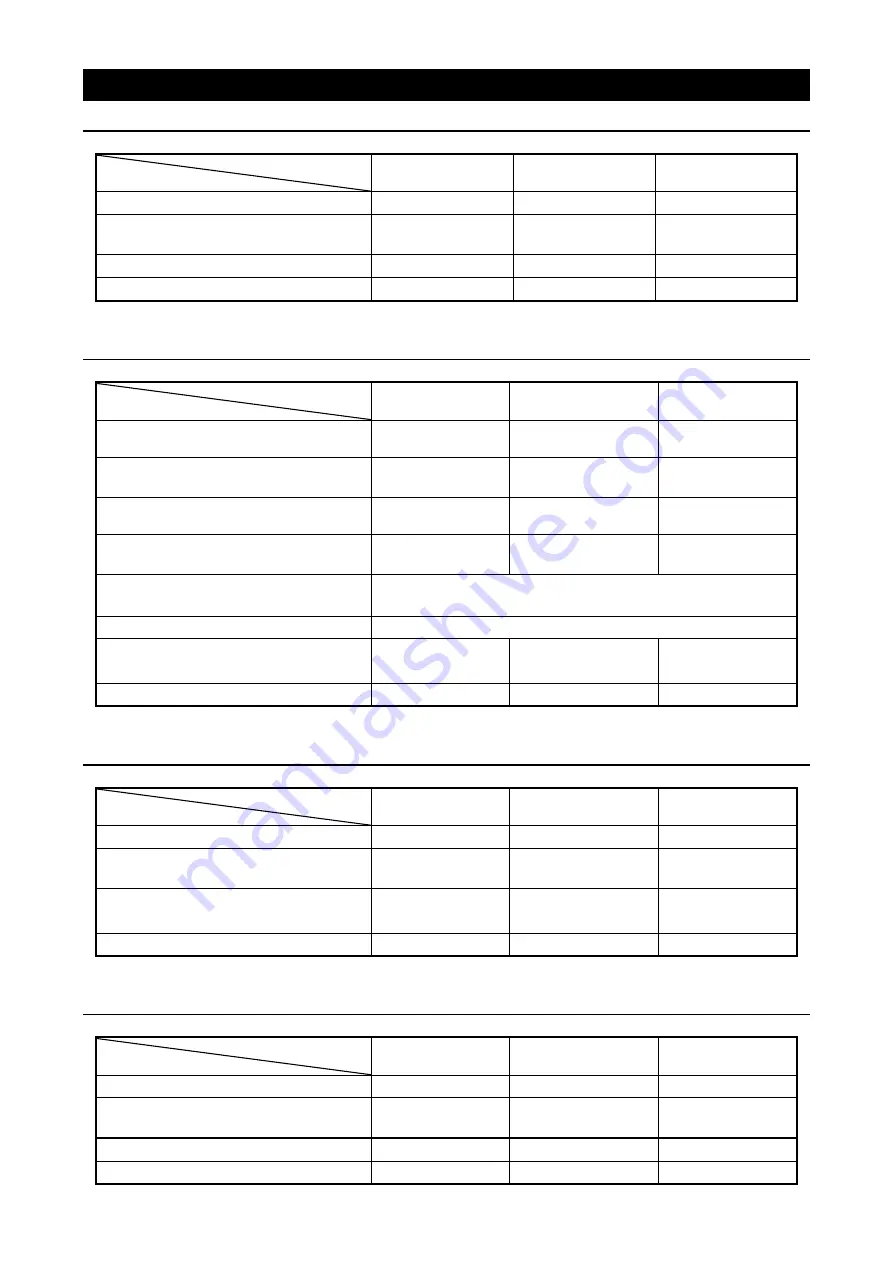

10. Specifications

Individual specification for standard type

Type

item

LDS-120

LDS-150

LDS-180

Standard discharge air quantity m

3

/min

12

16

19

Static pressure within the machine

Pa (mmH

2

O)

30(3)

59(6)

79(8)

External dimensions

W×D×H (mm)

1200×750×2400

1500×750×2400

1800×750×2400

Weight (Approx. kg)

290

330

370

Individual specification for air curtain type

Type

item

LDS-120A

LDS-150A

LDS-180A

Standard discharge air quantity m

3

/min

12

16

19

Static pressure within the machine

Pa (mmH

2

O)

30(3)

59(6)

79(8)

Air flow(m

3

/min)

8.4

11.2

13.3

Air flow pressure within the machine

Pa (mmH

2

O) Pa(mmH

2

O)

20(2)

35(3.6)

49(5)

Air flow duct

Each duct PVC with ID 400 mm OD 100 mm

Connected with a half flange

Applicable air supply duct

PVC with ID 211 mm OD 216 mm

External dimensions

W×D×H

(mm)

1200×750/1020

×2600

1500×750/1020

×2600

1800×750/1020

×2600

Weight (Approx. kg)

340

380

440

Individual specification for desk-top type

Type

item

LDS-120T

LDS-150T

LDS-180T

Standard discharge air quantity m

3

/min

12

16

19

Static pressure within the machine

Pa (mmH

2

O)

30(3)

59(6)

79(8)

External dimensions

W×D×H

(mm)

1200×750

×1550

1500×750

×1550

1800×750

×1550

Weight (Approx. kg)

130

150

170

Individual specification for low-ceiling type

Type

item

LDS-120J

LDS-150J

LDS-180J

Standard discharge air quantity m

3

/min

10

13

16

Static pressure within the machine

Pa (mmH

2

O)

25(2.5)

39(4)

59(6)

External dimensions

W×D×H (mm)

1200×750×2100

1500×750×2100

1800×750×2100

Weight (Approx. kg)

280

320

360