5

Maintenance Method

Daily Inspection and Maintenance

WARNING!

Disconnect the power cable from the power source when doing an inspection or maintenance

unless needed.

Perform the daily inspection and maintenance after returning the temperature of this unit to the

normal one.

Do not disassemble this unit.

CAUTION!

Use a well-drained soft cloth to wipe dirt on this

unit. Do not use benzene, thinner or cleanser for

wiping. Do not scrub this unit. Deformation,

deterioration or color change may result in.

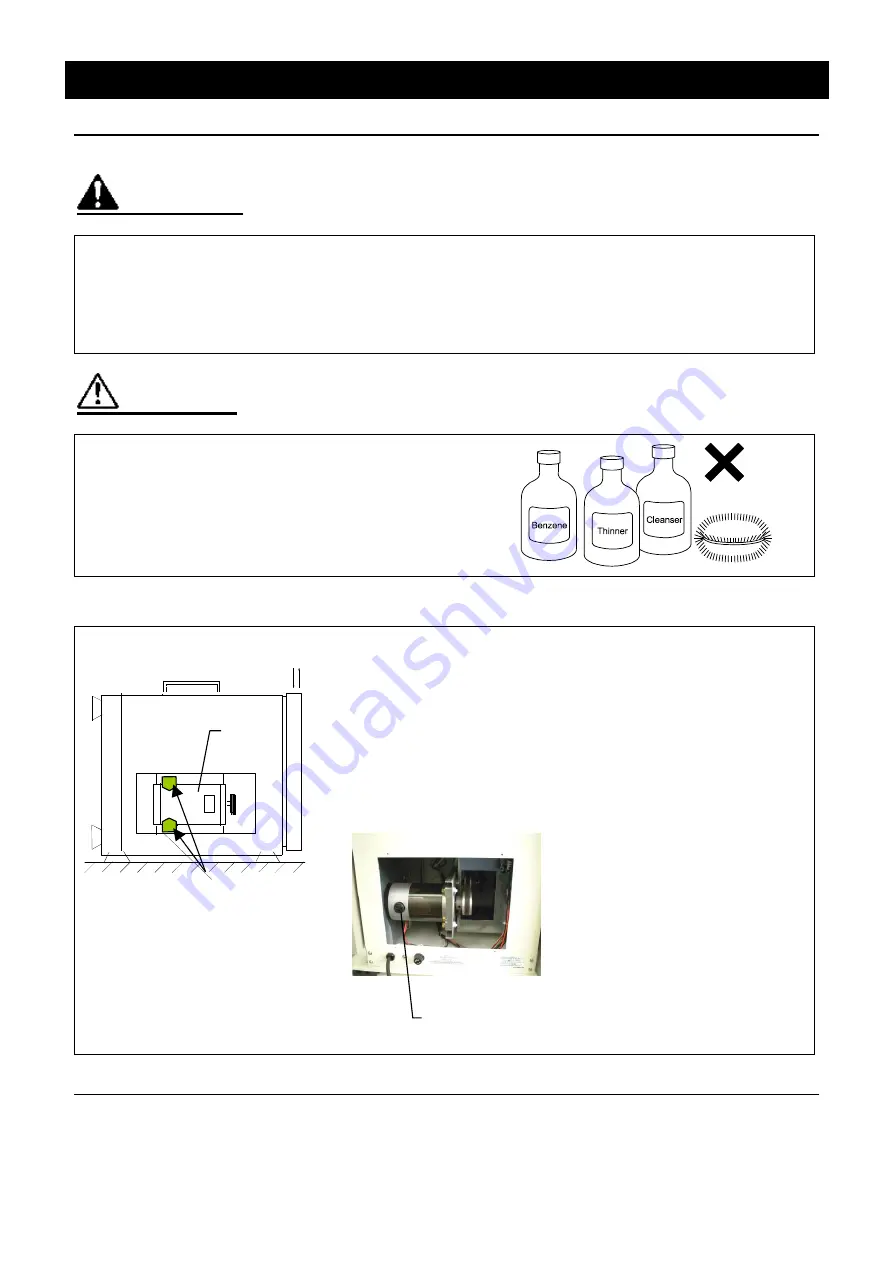

Replacement method of Motor Brush

Replacement of Motor Brush

Brush holder

Motor

Since the carbon brush of the motor is worn out as the motor is

operated for a long time, replace the carbon brush periodically.

Though the timing of the replacement is dependent on the

frequency of operation, check such a brush every 6 months.

When the inspection port cover is removed, the motor can be

seen. Two resin holders for fixing the carbon brush are

provided in the lower part of the motor. Use a coin, etc. to

loosen the groove on top of the holder. Change it with the

attached carbon brush, and replace it at the original place.

For any questions, contact the dealer who you purchased this unit from, or the nearest sales

division in our company.

Two brush holders

(Installed on the other side of this face shown in this photo)