ULTRA LOW FREEZER

ULF SERIES

MODEL

ULF401U / ULF501U / ULF601U / ULF701U

INSTRUCTION MANUAL

- FIRST EDITION –

•

Thank you for purchasing ULF Series Ultra Low Freezer of Yamato

Scientific.

•

To use this unit properly, read this "Instruction Manual" thoroughly

before using this unit. Keep this instruction manual around this unit

for referring at any time.

WARNING: Carefully read and thoroughly understand the important

warning items described in this manual before using this unit.

Yamato Scientific America Inc.

Santa Clara, CA

Summary of Contents for ULF Series

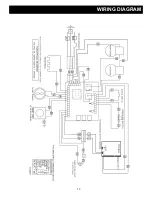

Page 15: ...13 WIRING DIAGRAM ...

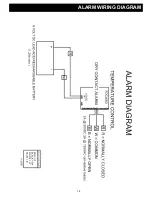

Page 16: ...14 ALARM WIRING DIAGRAM ...

Page 17: ...15 REFRIGERATION FLOW CHART ...