29

VF2400

6. Adjustments

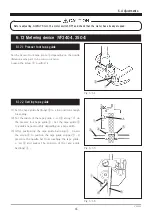

A timing gauge has the marks (

A, B, C, D, E

) for each

needle distance (Table 8).

Move the looper at the extreme right. Keep fitting the

right needle into the groove “V” corresponding needle

distance, and fit the looper tip to the gauge.

Then, tighten the screw ④ securely. (Fig. 6-13)

6.5.3 Using timing gauge

Fig. 6-15

針

C

D

B

AE

Fig. 6-16

Fig. 6-17

Fig. 6-18

0.5 -

1.0 ㎜

①

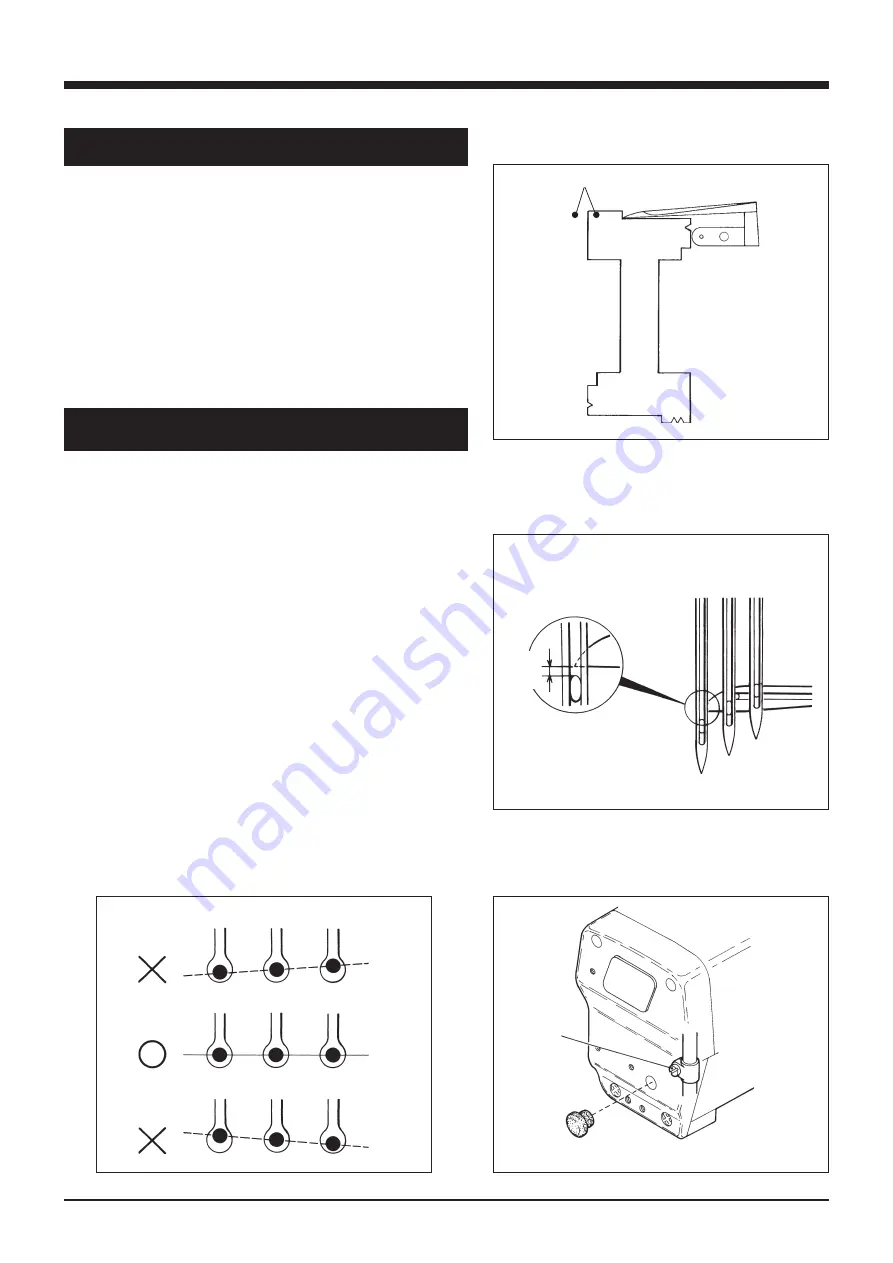

6.6 Height of needle bar

Check points:

◇ Needles should be inserted fully into the needle holes of

the needle clamp and fixed securely.

◇ Looper should be inserted fully into the looper holder

and fixed securely.

Adjusting:

(1) Install the needle to the left hole in the needle clamp.

(2) Check the looper is inserted into the looper holder

fully.

(3) Turn the handwheel until the looper tip meets the cen-

ter of the left needle.

(4) Loosen the screw ① of the needle bar bracket. Move

the needle bar up or down so that the looper tip passes

0.5 - 1.0 mm above the top of the needle eye.

(5) Tighten the screw ① securely. Check that the needles

drop in the centers of the needle holes of the stitch

plate respectively.