22

In the Event of Failure…

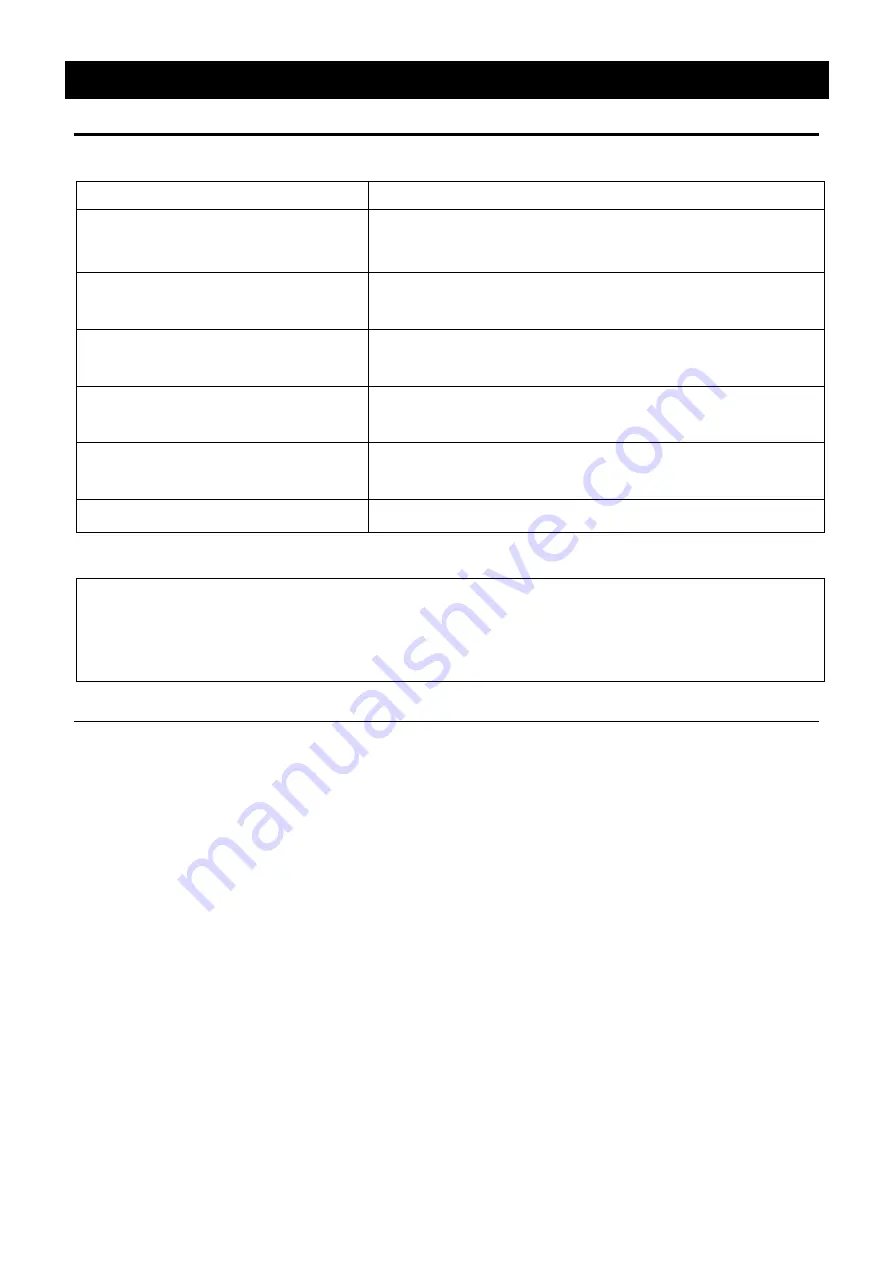

Trouble Shooting

Condition Possible

Causes

Power lamp on the control panel does

not light on when turning on the power

switch.

•

Power plug is not connected to the receptacle correctly.

•

Power

failure.

No water is supplied.

•

Defects in the raw water supply solenoid valve.

•

Insufficient pressure of water way or cut-off of water.

Water supply is not stopped.

•

Defects in the float switch.

•

Defects in the raw water supply solenoid valve.

No water is supplied to boiler.

•

Defect of float switch.

•

Defect of boiler water supply solenoid valve.

Heater does not turn on.

•

Defect of float switch.

•

Heater

disconnection.

Distillation does not stop.

•

Defect of float switch.

When power failure occurs…

•

When power is supplied after a power failure, the device automatically starts operation again with

the same state as just before the power failure. It is danger that the device starts unattached

operation after a power failure.

•

We recommend for you to turn off the switch of device if a power failure occurs during operation.

In the case if the error other than listed above occurred, turn off the power switch and primary

power source immediately. Contact the shop of your purchase or nearest Yamato Scientific

Service Office.