A05G069A

4

⚫

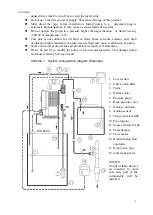

Notices of piping (Piping configuration consult scheme 1)

:

1.

If pump location is above chemical container, do not excess 2.0meters higher

than the chemical lowest level in the container and check valve must be installed

vertically. High suction head may lead fail inhalation. Permissible suction head

is affected by Liquid viscosity, specific gravity, pipeline conditions.(We do not

guarantee suction head of this product)

2.

When input hose is empty, pump may not able to suck liquid into pump

head automatically. In this case you can try to full the hose with liquid

then raise it up higher than pump head and start pumping. This procedure

may solve suction problem. (If a pipe injector will be install, install it after

pump can pump out normally. )

3.

The pressure loss cause by pump pulse should below 1.0 Kgf/cm2 ,otherwise the

pipe start to vibrate. In this case, a pulse reducer can be installed or reduce

piping length/elbow or increase pipe diameter.

4.

Be aware that pressure discrepancy between input output hose should higher

than the inner pressure loss of this pump otherwise, overfeeding even siphon

phenomenon may occur. In this case an anti-siphon/backpressure valve(both are

optional) should be installed.

5.

Fluid which is easy to gasify or vaporize (Ex. H

2

O

2

, most solvents). Gas in pump

head cause variation of flow rate. In this case purge the gas through drain

valve.

6.

Output pipe may install following devices to solve some problems

:

Pulse damper -To reduce pipe vibration especially pipe is long/thin/plenty of

elbows

Pressure gauge -To monitor output pipe pressure.

Release valve -To prevent pipe from rupture cause by exceptional high

pressure and secure operator against hazard.

Back-pressure -To keep constant pressure of output pipe and improve flow

valve rate stability.

Pipe injector -To connect hose/pipe to other pipe.

Anti-siphon - If pumping destination altitude is lower than source

Valve tank siphon phenomenon occur. In this case an anti-siphon

valve should be installed.