X4

10

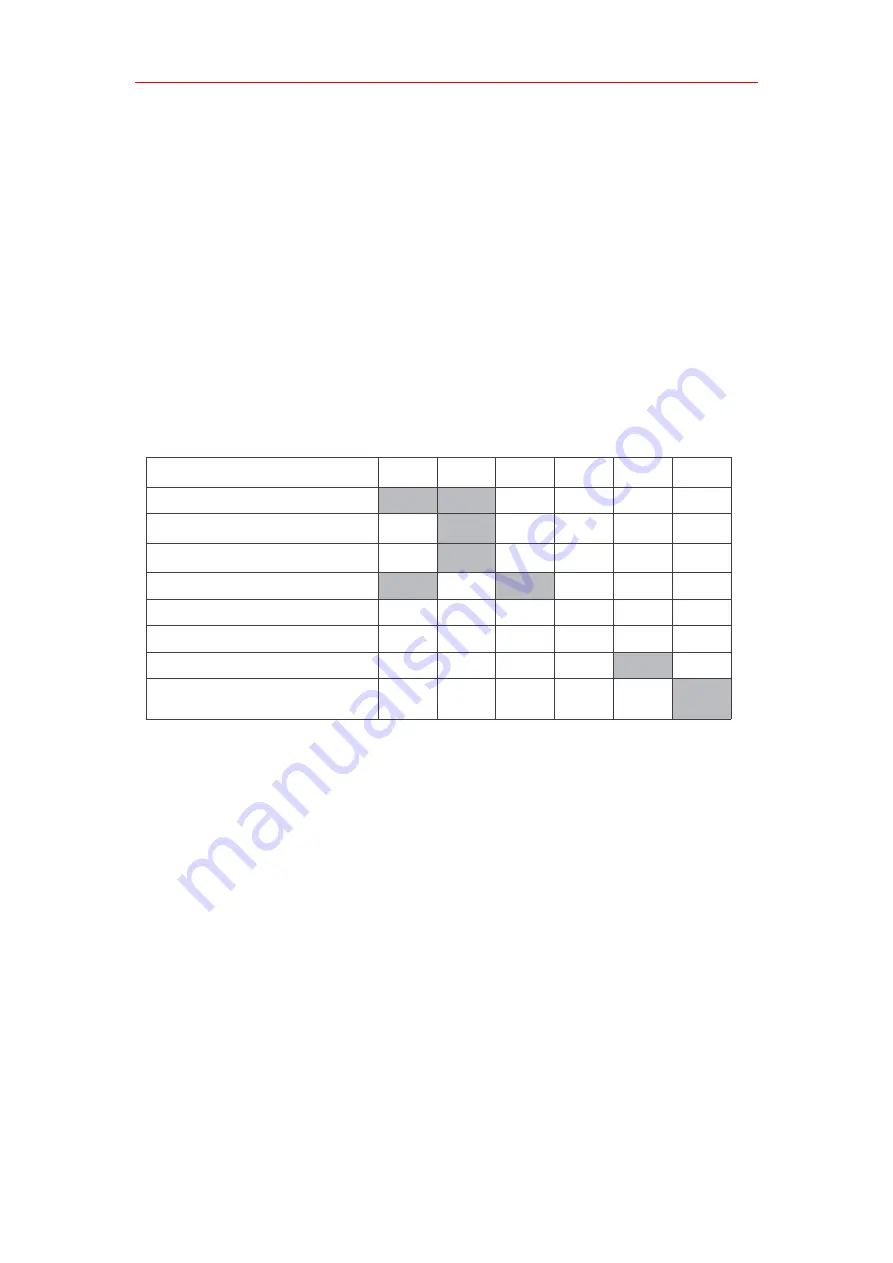

Machine life and operational safety must be ensured by proper and routine

maintenance of the machine. The routine maintenance requirements are tabulated

below. Under suitable working conditions, the maintenance interval can be changed,

which must be determined by the professional responsible for the maintenance.

To perform maintenance operations, the machine must be stopped (remove the start

switch key), so please read the safety section of the manual carefully.

Conditions of Use

●Ambient temperature: -10

℃~

40

℃

●The relative humidity of the air: 5%

~

70%

●No conductive dust, no explosion hazard environment

● An environment that does not contain gases or vapors that corrode metals

●Indoor use, ventilated, non-vibration environment, front and rear space at least

300mm

Maintenance schedule

Warranty

Warranty is not covered under the following conditions of use:

● Failure to perform maintenance in accordance with the maintenance manual may

result in mechanical damage or failure.

●The mechanical appearance or structure is obviously damaged due to improper

operation.

●Disassembly or modification not approved by the original factory.

●Damage due to weather or force majeure.

●More than 1 year of warranty or more than 1500 hours of use.

Maintenance operation

On

handover

Every10h Every50h Every100

h

Every200

h

Every500

h

Brush Disc Height Adjustment Check

Whether the brush plate is wired or

entangled

Squeegee Cleaning Complete

Inspection

Tank cover seal inspection

Screw and nut tightening inspection

Check the wear of the brush disc

Replacement of absorbent strips

Main brush and drive system motor

carbon brush inspection and

replacement

Summary of Contents for X4

Page 1: ...X4 FLOOR SCRUBBER Operating instruction...

Page 17: ...X4 1...