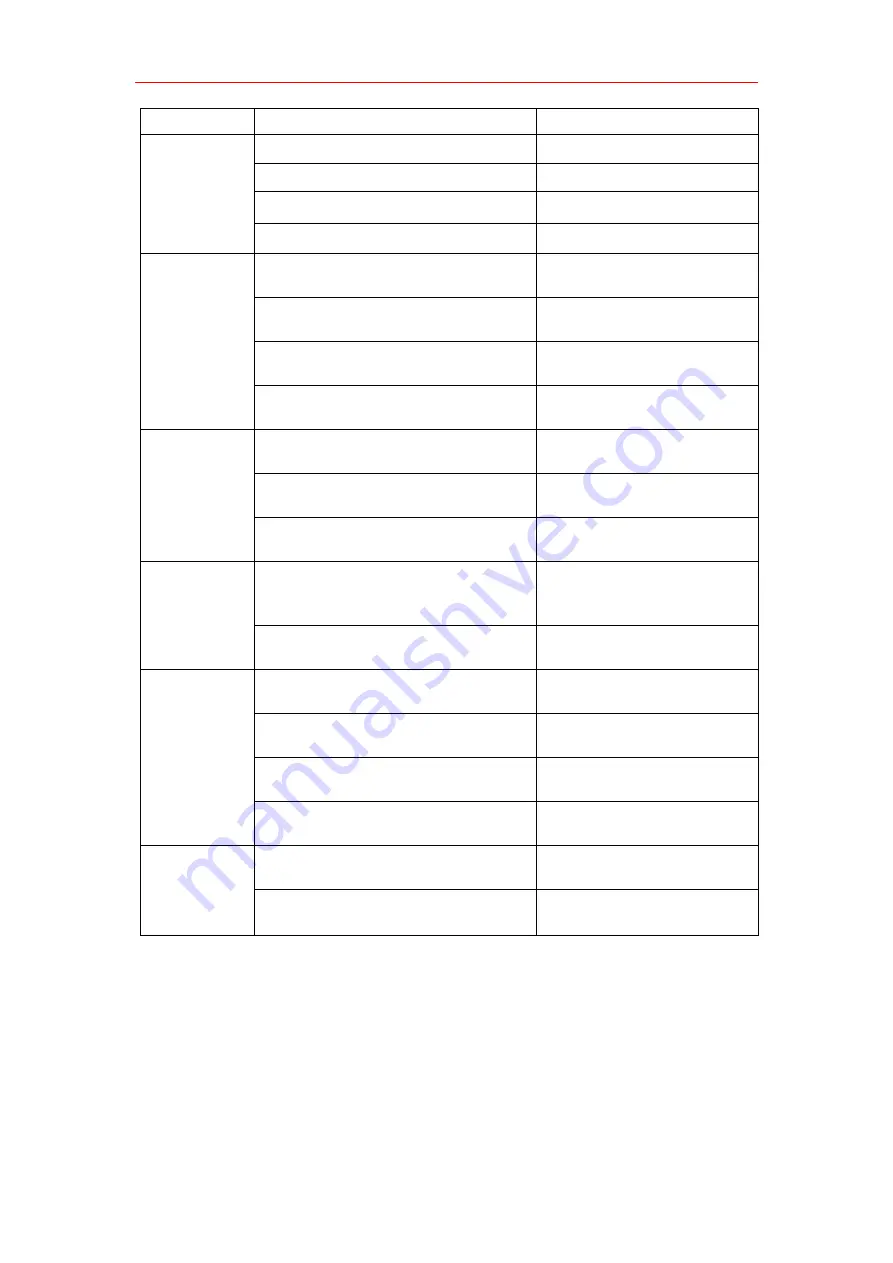

X4

9

Problem

Reason

Solution

Machine

doesn’t work

Battery dead

Charge

Battery failure

Replace the battery

Battery wiring loose

Tighten the battery wiring

Main fuse blown

better fuse

Brush motor

does not work

The brush head is lifted off the

ground

Lower the brush head

Brush disc motor circuit breaker

tripped

Reset brush circuit

breaker button

Main brush switch failure

Please contact the

service center

Motor carbon brush wear

Please contact the

service center

fan not working

Suction motor noise is too loud

Please contact the

service center

Suction motor burned out

Replace the suction

motor

Carbon brush wear

Please contact the

service center

Little or no

water flow out

Clogged water tank drain valve or

water pipe

Clean or replace the

solution tank drain valve

Drain valve closed

Open the drain valve

Inefficient

recycling of

sewage

recovery tank full

Drain the recovery tank

Absorbent strip wear

Replace the absorbent

strip

Suction motor failure

Replace the suction

motor

Damaged recovery tank seal

Replace the seal

Shorter

working hours

The voltages of the two batteries

are not equal

Please contact the

service center

Battery charging failure

Repair or replace the

charger

Chapter 5 Maintenance

Summary of Contents for X4

Page 1: ...X4 FLOOR SCRUBBER Operating instruction ...

Page 17: ...X4 1 ...